Maximizing Manufacturing Excellence

CNC Machining as a Service

Are you tired of grappling with the limitations of traditional CNC milling? Fortunately, CNC machining services offer a liberating alternative, allowing you to unlock the full potential of CNC milling technology. These services are a groundbreaking manufacturing approach that grants businesses access to top-tier CNC milling capabilities, all without the need for hefty investments in equipment or in-house machinists.

The benefits of CNC machining services are plentiful and profound. They encompass heightened efficiency, cost reduction, and accelerated time-to-market. Moreover, CNC machining service providers extend a comprehensive array of advanced CNC milling techniques, including high-speed milling and five-axis milling, enabling businesses to fabricate intricate and pinpoint-precise prototypes and components.

The key lies in selecting the right CNC machining service provider. Doing so grants access to cutting-edge CNC milling technology, a wealth of technical expertise, and unrivaled customer support. So, let’s embark on a journey into the realm of advanced CNC machining services and discover how they can propel your business to new heights.

State of CNC Milling Today

Overview of CNC milling

Limitations of Traditional CNC Milling

Introduction to Advanced CNC Milling Services

Advanced CNC Milling Techniques:

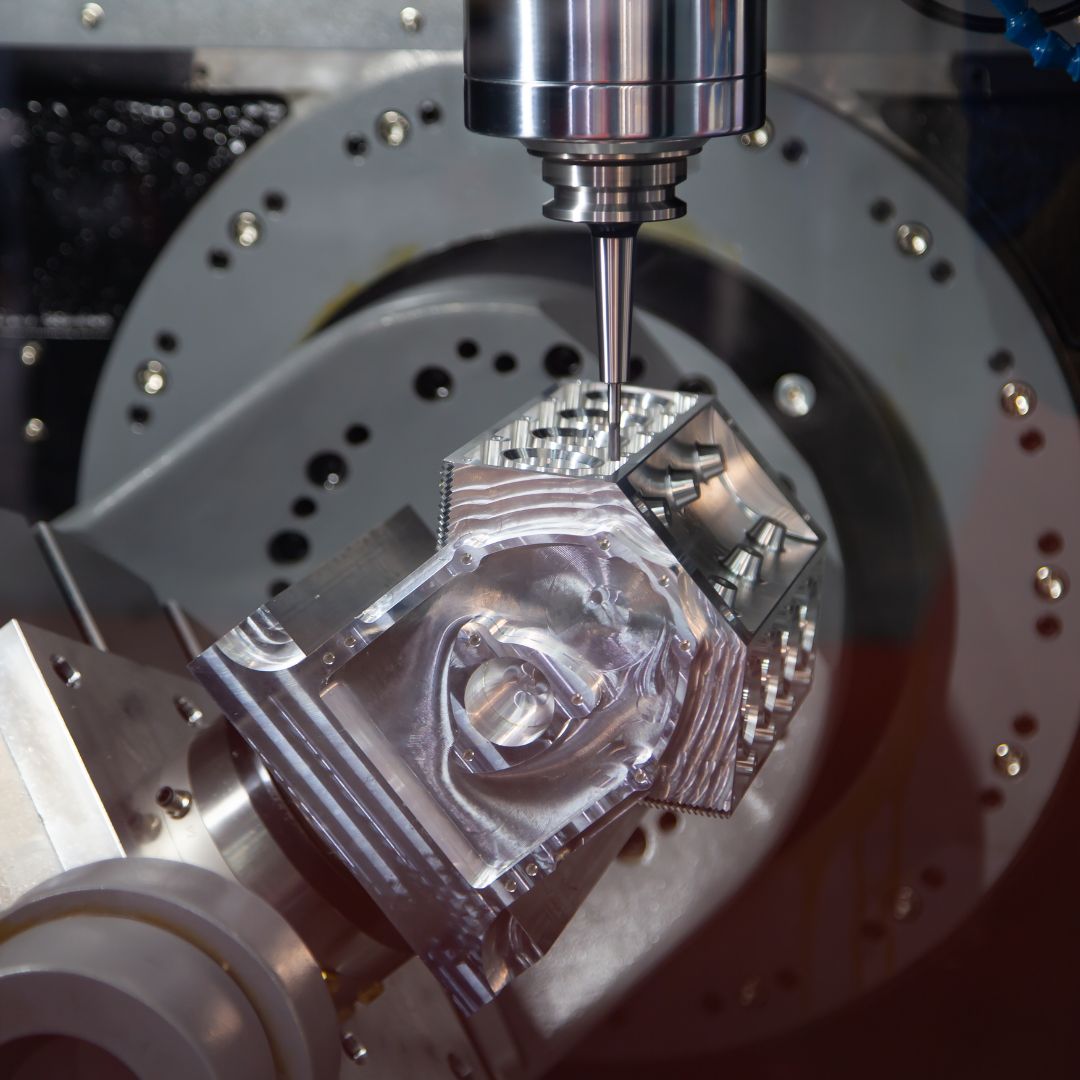

Gone are the days when traditional CNC milling was the only way to achieve precision part-making. This is where Advanced CNC Milling Services comes in. With a variety of techniques available, it unleashes the full potential of Machining as a Service (MaaS).

One such technique is High-speed Milling that uses a spindle speed of 20,000 RPM or more. This allows for faster material removal rates, which means parts can be produced in a shorter amount of time. High-efficiency Milling is another technique that focuses on material removal rates, as well as optimizing tool life. This is achieved by controlling cutting forces, chip formation, and heat generation.

Five-Axis Milling is yet another technique that offers precise control over part geometry. With the ability to access five sides of a part, it can produce complex geometries with ease. Finally, Cryogenic Milling, which involves cooling the workpiece to cryogenic temperatures, introduces added benefits such as reduced tool wear and improved surface finishes.

With these advanced techniques, it’s no wonder that many industries such as Aerospace, Automotive, Medical, Consumer Products, and Industrial have adopted them. The impact of these techniques is vast as they have made it possible to produce complex and precise parts, which would have been impossible with traditional CNC Milling.

The benefits of these advanced techniques are many; they offer precision, speed, cost-effectiveness, scalability, and quality control. However, choosing the right CNC Milling Service Provider is crucial. One must consider factors like experience and reputation, technological expertise, quality management, turnaround time, and customer support.

Advanced CNC Milling Techniques have revolutionized the manufacturing industry. With precision, quality, and speed guaranteed, one can produce complex geometries in a short amount of time. The possibilities are endless, and the future is exciting.

Applications of Advanced CNC Milling

The applications of advanced CNC milling are endless. Aerospace industries have been able to use CNC milling services to fabricate light-weight parts that are critical for fuel savings and reducing emissions. Automotive industries have also benefitted from the application, and they have been able to produce high-precision and complex parts for improved vehicle design.

Medical and dental specialists have embraced the technology to produce highly intricate and sophisticated prosthetics and implants, which fit seamlessly into the human body.

Consumer producers have been able to manufacture complex components in a cost-effective and timely manner while reducing the time required to get their products to market. The industrial sector has not been left behind either, with the technology being used to produce parts that meet specific requirements.

Choosing the right CNC milling service provider should be a top priority, as it will help ensure that you receive parts that meet your requirements. Factors such as the provider’s experience and reputation, technological expertise, quality management, turnaround time, and customer support should come into play when selecting a provider.

Ethereal Machine's MAAS (Machining As A Service)

Unlocking CNC Excellence for Your Business

Understanding the MAAS Process

1. Upload a CAD File

2. Design Analysis is Performed

3. Manufacturing Begins

4. Inspection Done & Parts Shipped

Benefits of MAAS with Ethereal Machines

Why choose us as your CNC Machining provider

Fair Pricing for CNC Machining Projects:

Rapid Iterations:

Quality Assurance:

Convenience of Obtaining an Instant Quote:

Conclusion

In conclusion, advanced CNC milling services, such as Ethereal Machine’s MAAS (Machining As A Service), have revolutionized the manufacturing industry by providing precise, efficient, and cost-effective machining solutions. MAAS enables businesses to access advanced technologies like high-speed and five-axis milling, resulting in faster turnaround times and higher quality products. Many industries, such as aerospace, automotive, medical, consumer products, and industrial, have benefited from these services.

Choosing the right CNC milling service provider is critical to ensure a smooth and successful project. Look for experienced and reputable providers like Ethereal Machines, with technological expertise, quality management systems, and good customer support. Ultimately, the benefits of advanced CNC milling services are precision, speed, scalability, cost-effectiveness, and quality control. With these advantages, businesses can bring their big ideas to life and stay ahead of the competition.

Views: 558