Choosing the Right Perfect Materials for CNC Machining Project

Understanding the Importance of Material Selection

Material selection – it’s not just for reality TV shows like The Bachelor; it’s a critical aspect of manufacturing, especially in the realm of CNC machining. Choosing the right materials for this process demands careful consideration. Settling for a “good enough” material just won’t make the cut (pun intended).

So, why is material selection so pivotal in CNC machining? It all boils down to compatibility. While CNC machining can work with various materials, from metal to wood, not all materials are created equal. Just because a material can be machined doesn’t mean it’s the best fit for your project. Think of it like building a winning baseball team; you need players who can hit home runs, not just swing a bat.

When selecting materials, there are several crucial factors to ponder:

Intended Use: Consider how your part will be used. Will it face corrosive elements? Choose a material naturally resistant to corrosion to avoid premature failure. Compliance with industry regulations is non-negotiable.

Weight: Weight is crucial, particularly for automotive and aerospace applications. Opt for low-density metals or lightweight plastics like ABS, but be ready to trade some strength for reduced weight.

Strength: Strength isn’t one-size-fits-all. Different types like tensile strength and wear-resistance matter depending on your part’s needs. Factor in temperature requirements; some materials can’t handle high heat.

Budget: Material costs impact your project’s bottom line. Seek a balance between performance and cost-efficiency. High-cost materials may not be practical due to CNC machining’s material wastage.

Choosing the perfect material for your CNC machining project isn’t simple. It involves navigating the implications of material selection, meeting project requirements, adhering to industry standards, considering strength and weight needs, evaluating the budget, and understanding the unique properties of materials. It’s a complex task, but that’s what makes engineering so exhilarating. So, fellow engineers, choose your materials wisely and keep innovating!

Considering End-Use and Application

When choosing a material for CNC machining, it’s important to consider the purpose and end-use of the part. If the part will be used in a high-stress environment or exposed to corrosive elements or extreme temperatures, these factors will play a significant role in material selection.

For corrosion resistance, stainless steel is an excellent choice. It naturally resists corrosion, making it suitable for parts exposed to moisture or other corrosive substances.

Regulations from organizations like the FDA and FAA also need to be taken into account to ensure safety and reliability. Complying with industry-specific standards is crucial for the final product’s integrity.

Now, let’s discuss some suitable materials for different applications. Aluminum alloys are popular due to their lightweight and sturdy properties, making them ideal for industries like aerospace and automotive, where weight reduction is important. If you’re looking for a material with elegance, titanium is a great option. It offers a unique combination of strength, lightness, and corrosion resistance.Plastics like ABS provide a balance between weight, strength, and cost-effectiveness. They are suitable for meeting performance requirements without being too expensive.

Additionally, there are other materials to consider such as brass, copper, and exotic alloys. The world of CNC machining materials offers a wide range of options.

By considering the purpose of the part, end-use, corrosion resistance, regulations, and the suitability of different materials for various applications, you can choose the perfect material for your CNC machining project.

Weighing Strength and Weight Requirements

When it comes to CNC machining, it’s important to consider the strength and weight requirements of your project. The chosen material should have the necessary strength to hold up under pressure and withstand heavy loads or constant wear and tear.

Measuring strength can be done through parameters like tensile strength, which measures a material’s ability to withstand pulling forces, and wear resistance, which determines its ability to withstand friction and abrasion. Considering temperature requirements is also crucial, as the material needs to be able to handle extreme heat or cold without losing its shape or integrity.

Balancing weight and strength is a challenging task, but there are lightweight material options available that offer a perfect balance. These lightweight materials, such as aluminum alloys and advanced plastics, provide strength while keeping the weight low. They offer a performance that may not match heavyweight materials but are like David to Goliath, defying expectations and proving that size isn’t everything.

So, when it comes to CNC machining, choosing the perfect material for your project requires careful consideration and evaluating the balance between strength and weight. Explore the world of lightweight materials and find the one that suits your needs. Your CNC masterpiece awaits!

Budget Considerations and Material Costs

Budget considerations and material costs are essential factors when it comes to CNC machining. It’s crucial to find a balance between maximizing the desired material properties and performance while minimizing expenditure.

Evaluating the pros and cons of different materials is necessary to find a material that meets project requirements without exceeding the budget. Factors like durability, strength, and cost-effectiveness should be carefully considered.

Before making a final decision, it’s important to evaluate the project budget. This serves as a roadmap for material selection and helps determine which materials are financially feasible.

The cost-efficiency of a project is also affected by the amount of scrap material produced during CNC machining. It’s important to consider how much waste is generated by the chosen material and ensure it aligns with the budget goals.

Finding the perfect balance between material properties and expenditure is key in budget considerations and material costs for CNC machining. So, explore your options and make informed decisions to conquer the world of CNC machining with your budget-friendly knowledge!

Common Materials for CNC Machining

When it comes to CNC machining, there is a wide range of materials to choose from, each with their own unique properties and applications. Let’s explore some commonly used materials in CNC machining:

Aluminum Alloys: Aluminum alloys are lightweight and offer an excellent strength-to-weight ratio. They are widely used in various industries, including automotive and aerospace, due to their thermal conductivity and corrosion resistance. They provide great performance at a reasonable cost.

Stainless Steel: Stainless steel is known for its corrosion resistance, making it suitable for parts exposed to harsh environmental conditions. It offers excellent strength, durability, and a polished finish, making it a popular choice in medical devices, kitchen appliances, and architectural components.

Titanium: Titanium is a material with high strength, low density, and high corrosion resistance. It finds applications in the aerospace and medical industries where strength, lightness, and biocompatibility are crucial.

Plastics: Plastics like ABS, acrylic, and nylon are widely used in CNC machining due to their versatility, low cost, and ease of machining. They offer designers and engineers a range of options for creating lightweight and intricate parts. Plastics are commonly used in the electronics, automotive, and consumer goods industries.

In addition to these commonly used materials, there are other options worth considering. Copper, brass, and bronze offer unique properties such as electrical conductivity and antimicrobial properties, making them suitable for specific applications. Ceramics and composites provide excellent heat resistance and strength for specialized projects.

When selecting the perfect material for your CNC machining project, it’s important to understand your specific requirements. Consider factors like end-use, corrosion resistance, temperature requirements, strength, and weight. Evaluate the machining environment and balance cost-effectiveness with manufacturability. By making informed decisions based on these considerations, you can ensure the success of your project.

So, the world of CNC materials is vast and full of exciting possibilities. Whether you choose aluminum alloys for their lightweight performance, stainless steel for its corrosion resistance, titanium for its strength, or plastics for their versatility, there’s a material out there to suit your needs. Embrace the variety, weigh your options, and create amazing CNC machined parts with the perfect material.

Choosing the Perfect Material for Your Project

When it comes to CNC machining, selecting the perfect material for your project is crucial for success. Understanding the specific requirements of your project is the first step in making an informed decision. Consider factors such as the part’s purpose, desired material properties, and performance expectations.

Each project has unique needs, so it’s important to evaluate the project requirements carefully. Will the part be exposed to high temperatures or corrosive environments? These considerations will narrow down the pool of viable materials. For example, if you’re constructing a part that requires high strength and heat resistance, materials like stainless steel or titanium might be suitable options.

But it’s not just about performance; you also need to evaluate the machining environment. Different materials react differently to varying cutting speeds, tool materials, and coolants. Machining temperature, humidity, and the presence of contaminants can all impact the final product. Ensuring compatibility between the material and the machining environment will lead to improved productivity, reduced costs, and a higher-quality finished product.

While performance and compatibility are crucial, cost-effectiveness and manufacturability should not be overlooked. Material costs play a significant role in determining the overall project budget. Selecting a material that maximizes desired properties while minimizing expenditure is the ultimate goal. It’s essential to carefully evaluate your budget before making any final decisions.

In order to choose the perfect material for your project, you need to consider all the factors mentioned above and make informed decisions based on a comprehensive understanding of your project requirements, material properties, and machining environment. Balancing all these elements will lead to successful projects that meet the desired outcomes.

So, don’t rush into material selection. Take the time to evaluate your project’s specific needs, consider the material properties and performance requirements, and assess the machining environment. By considering cost-effectiveness and manufacturability, you can make informed decisions that will ensure the success of your CNC machining projects.

Conclusion

Choosing the right material is paramount in CNC machining, ensuring the success and longevity of your project. No one wants their masterpiece to crumble or fail under stress, right? To make an informed choice, you must start by understanding your project’s specific requirements. What’s the intended purpose of the part you’re manufacturing, and will it be subjected to challenging conditions? Answering these questions narrows down the list of materials that can withstand the test of time. Additionally, consider the material properties and performance characteristics that align with your project’s unique demands. Whether it’s strength, heat resistance, or weight, finding the right balance is crucial.

Furthermore, don’t underestimate the impact of the machining environment. Different materials respond differently to factors like temperature and humidity, which can significantly affect the machining process and the quality of the final product. Therefore, meticulous consideration of these variables ensures a seamless manufacturing process and a finished product that meets your high standards. Lastly, remember that cost-effectiveness and manufacturability are key factors. Evaluate your project budget and select a material that maximizes the desired properties while minimizing expenditure. Keep an eye on the part’s weight, too, as it can directly influence overall cost-effectiveness. Armed with this understanding, you’re well-equipped to embark on your CNC machining journey, creating robust, cost-efficient products that stand the test of time.

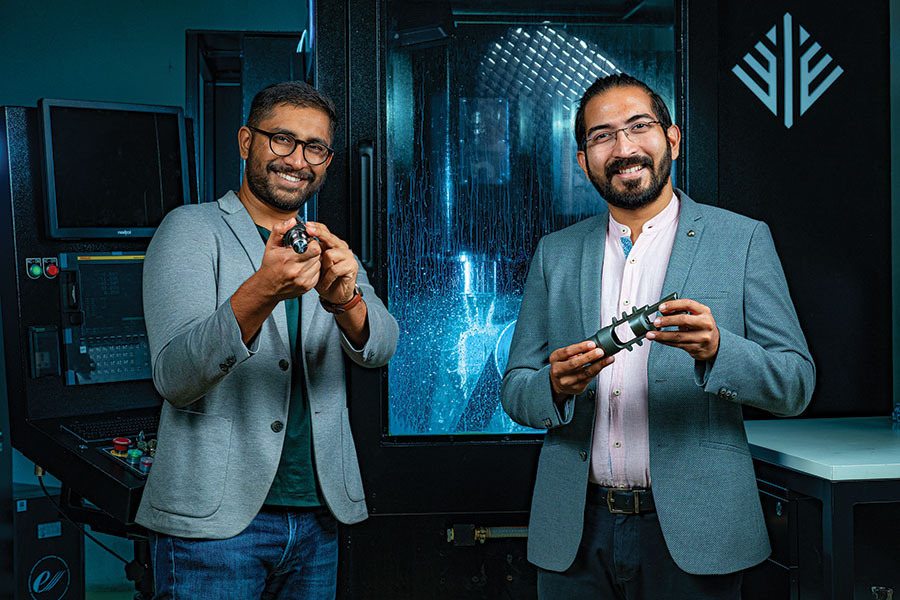

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 580