CNC Machining's Role in Advancing Space Exploration

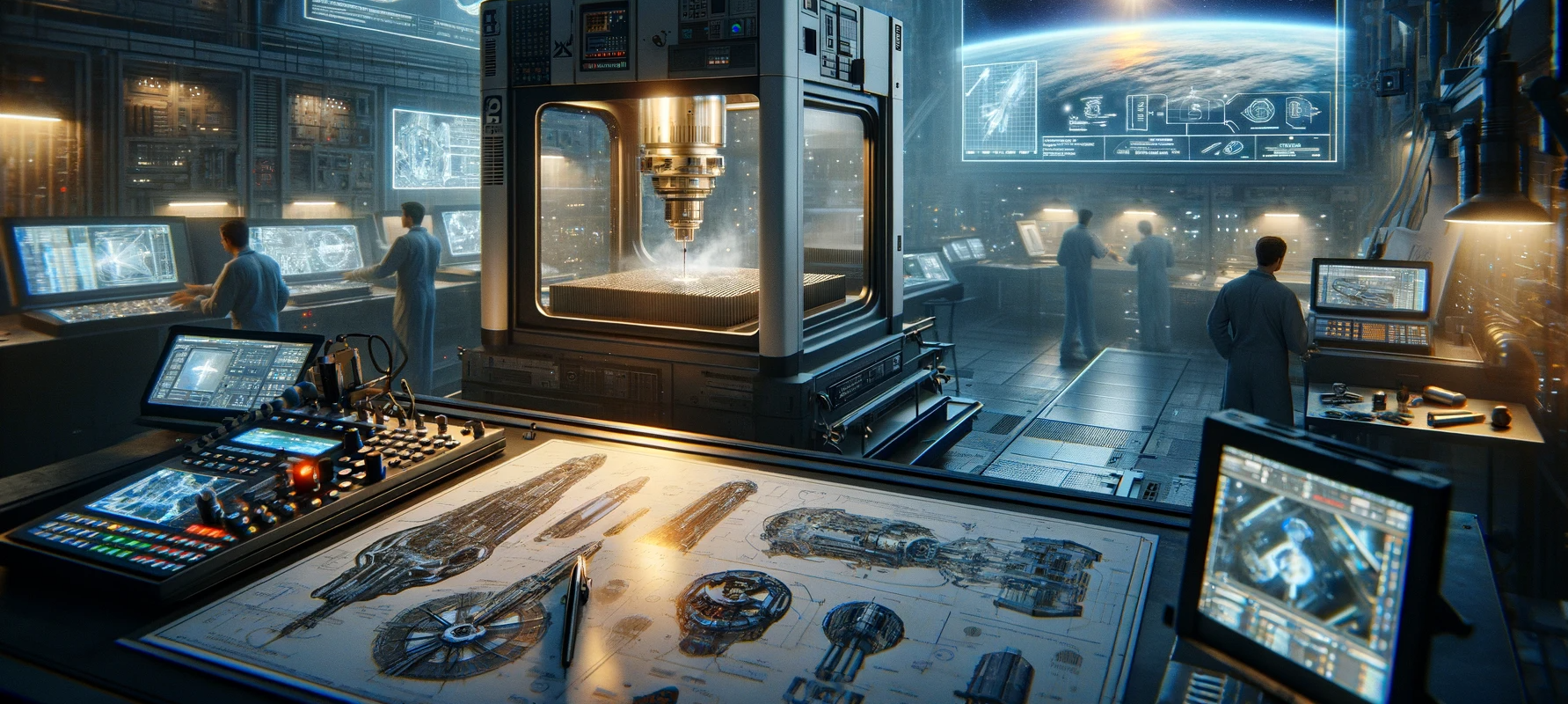

In this quest, CNC (Computer Numerical Control) technology emerges as a game-changer, outperforming traditional manufacturing methods with its unparalleled accuracy, efficiency, and versatility. It has become an indispensable tool in the arsenal of space exploration. This section will explore the pivotal innovations and evolving trends in CNC machining, highlighting how this technology is adapting to and shaping the demands of space-grade applications. Let’s take a closer look at how CNC technology plays a crucial role in fashioning components that can brave the harsh conditions of space travel. These components need to endure everything from blazing temperatures to the vast emptiness of space, requiring the kind of precision engineering that only CNC machining can provide.

Pushing the Limits of CNC for Deep Space Missions

Material Solutions for Space's Extreme Challenges

One of the most notable innovations is the development of new materials specifically designed for space applications. These materials must withstand extreme conditions, from the bone-chilling cold of deep space to the searing heat of re-entry into Earth’s atmosphere. For instance, materials like Titanium-Aluminide have gained popularity due to their high strength-to-weight ratio and excellent high-temperature performance, making them ideal for engine components and structural frames. Ethereal Machines has been at the forefront of adopting such materials, constantly upgrading our CNC machines to handle these advanced materials with precision.

a) The Demand for Exotic Materials in Space

- The vastness of space exposes materials to conditions like intense radiation, vacuum, and severe temperature fluctuations.

- This necessitates the use of exotic materials such as titanium alloys and advanced polymers. These materials are specifically chosen for their resilience and ability to withstand space’s harsh conditions.

b) Precision Machining for Extreme Conditions

- CNC machining steps up to meet the rigors of space by precisely shaping these materials. The accuracy and precision of CNC machining are crucial in ensuring that each component meets the exact specifications required for space applications.

- The role of CNC in machining these materials extends beyond mere shaping. It involves ensuring that these materials possess the necessary thermal stability and radiation resistance. This aspect is critical, considering the unforgiving nature of space.

c) Achieving Thermal Stability and Radiation Resistance

- Thermal stability is vital for materials in space to withstand drastic temperature changes. CNC machining aids in structuring materials in a way that their thermal properties are optimized for such fluctuations.

- Similarly, radiation resistance is a crucial factor. Materials machined via CNC techniques are engineered to endure high levels of cosmic radiation, a prevalent threat in space.

d) CNC Machining: A Critical Contributor to Space Exploration:

- The role of CNC machining in preparing materials for space exploration is not just a matter of manufacturing; it’s a matter of engineering survival in extreme conditions.

- The precision and capabilities of CNC machining in handling these exotic materials directly contribute to the success and safety of space missions

Precision Engineering for Critical Space Components

In the vast expanse of space, even the tiniest measurement holds immense importance. When it comes to crafting vital components like engine parts and life support systems for spacecraft, precision is not just a preference – it’s an absolute necessity. This is where CNC machining steps in, wielding unparalleled precision to meet ultra-fine tolerances crucial for the functionality and safety of these critical systems. The remarkable surface finishes achieved through CNC techniques play a pivotal role in boosting the performance and durability of these components, equipping them to withstand the unforgiving rigors of space exploration.

In the world of aerospace manufacturing, the pursuit of pushing the limits is an unending quest. Innovations such as 5-axis machining and precision machining represent the cutting edge of this relentless drive for advancement. These advanced techniques open the door to creating intricately detailed and previously unimaginable designs. By diving into real-life examples, it becomes clear that these advanced CNC methods are not only revolutionising production timelines, but also elevating the standard of aerospace components, ultimately leading to a significant boost in overall manufacturing efficiency.

a) The Precision of Small Dimensions

- The quest for space exploration hinges not just on grand designs but also on the minutiae of small dimensions. The precision of these tiny components can mean the difference between success and catastrophic failure in the harsh environment of space. This is where CNC machining shines, turning materials into precise parts with tolerances measured in microns.

- Understanding the critical nature of these small dimensions, Ethereal Machines employ state-of-the-art CNC technology to achieve the high level of precision required for aerospace components. Our machines are equipped with advanced calibration and measurement systems, ensuring that every cut, mill, or drill is executed with exacting precision.

- For example, consider the intricate fuel injection nozzles used in rocket engines. These nozzles must deliver fuel with precise timing and in exact quantities to ensure efficient combustion. Any deviation, however slight, could lead to inefficient fuel burn and, consequently, mission failure. Ethereal Machines’ CNC equipment is capable of crafting these nozzles with the precision necessary to meet these stringent requirements.

- Moreover, the reliability of communication systems in space depends heavily on the precision of their micro-components. These tiny parts must fit together perfectly to ensure clear and uninterrupted communication between astronauts and mission control. Ethereal Machines understands this imperative and has continually refined its CNC processes to meet the exacting standards of the aerospace industry.

b) Challenges and Solutions in CNC for Space

- Space exploration presents a unique set of challenges, from the need to create components that can withstand extreme temperatures and radiation to the demand for lightweight yet strong materials. Ethereal Machines rise to these challenges with innovative solutions and a forward-thinking approach.

- One of the primary challenges is the extreme conditions that space components must endure. Our response has been to focus on materials and techniques that are up to the task. We work with advanced alloys known for their strength and durability, and our CNC machines are calibrated to handle these materials with the precision required for space applications.

- Facing yet another hurdle is the demand for lightweight components. Even a single gram of excess weight on a spacecraft necessitates more fuel, escalating the mission’s expenses and intricacies. Enter Ethereal Machines, utilising cutting-edge machining methods to meticulously eliminate material, thereby trimming down weight without sacrificing the component’s durability.

Conclusion

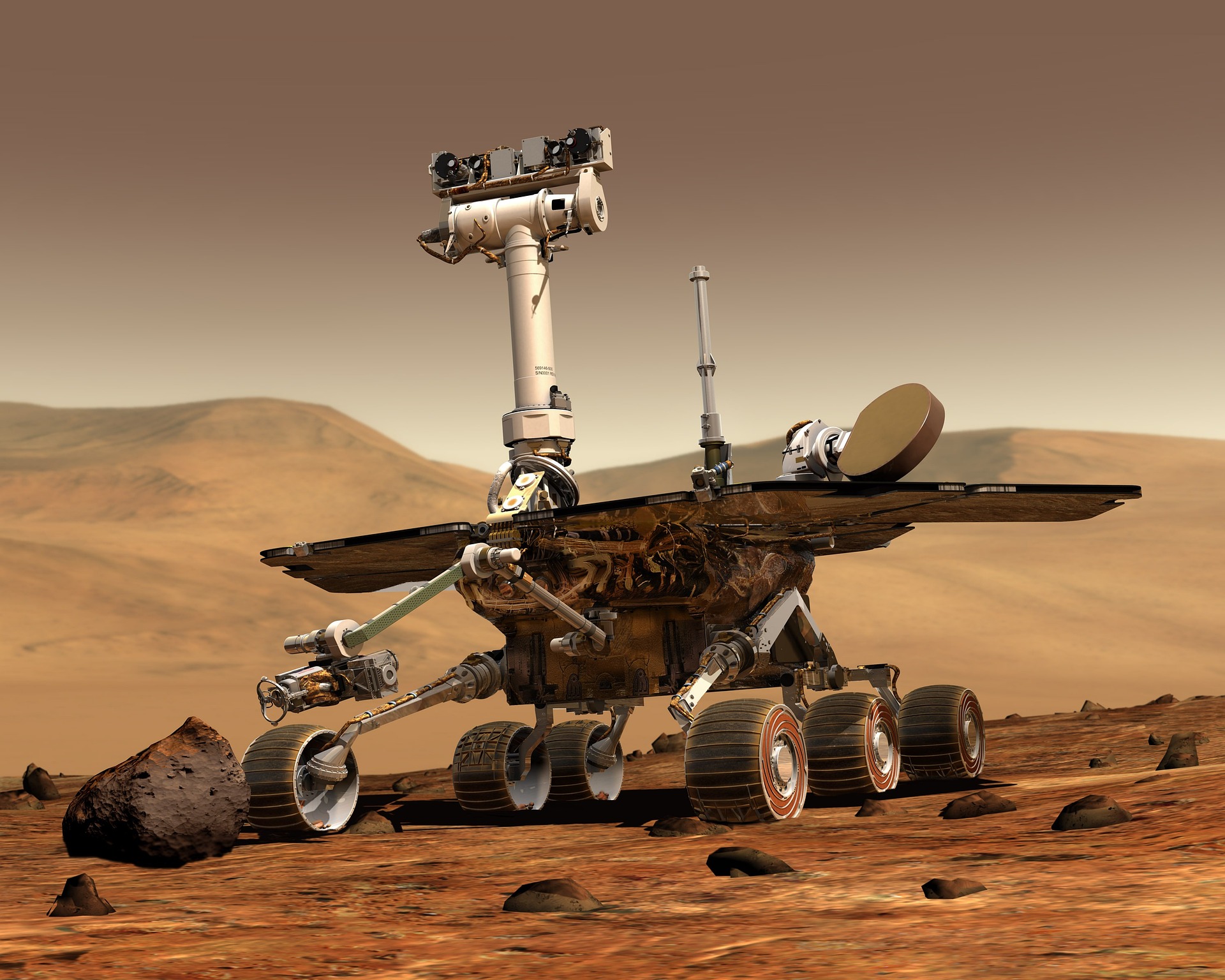

In the vast expanse of space exploration, the role of CNC machining cannot be overstated. From shaping NASA’s Perseverance Rover to fueling the endeavors of SpaceX and Blue Origin, CNC machining stands as a pillar of innovation and progress. In the unforgiving environment of space, where accuracy and dependability reign supreme, CNC machining represents the pinnacle of human creativity, transforming ambitious visions of Mars and beyond into tangible realities.

Ethereal Machines, with its profound expertise in the deep tech industry and unwavering commitment to CNC machines, has become a byword for precision, ingenuity, and trustworthiness. As space exploration progresses toward commercial tourism and more ambitious missions, the significance of CNC machining is poised to soar, symbolising the fusion of engineering resilience and technological exactitude. This heralds only the dawn of a future brimming with opportunities, with CNC machining at the forefront of space exploration.

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 476