Engineering Tomorrow’s Drones – Precision and Challenges in Modern Manufacturing

In the rapidly evolving landscape of drone technology, the ability to manufacture drones that are both highly efficient and robust is more crucial than ever. Drones have transcended their origins as mere hobbyist gadgets to become indispensable tools across a myriad of industries, including agriculture, construction, public safety, and environmental monitoring. Their capacity to access difficult-to-reach areas, provide real-time insights, and perform tasks with high precision makes them invaluable in today’s technology-driven world.

The drone industry is experiencing unprecedented growth, driven by continuous technological advancements and an increasing demand for innovative applications. According to the latest report by Research and Markets – Global Drone Market Outlook 2022, the global drone market is expected to reach $58.4 billion by 2026, growing at a compound annual growth rate (CAGR) of 16.4% from 2021. This expansion underscores the critical role drones will play in the future, prompting manufacturers to innovate continually and overcome the challenges associated with drone production.

Manufacturing drones presents unique challenges that require specialised solutions. These challenges include reducing weight without compromising strength, ensuring scalability in production, and maintaining cost efficiency. Ethereal Machines, a leader in precision and customization, is at the forefront of addressing these challenges through advanced manufacturing techniques. By leveraging their expertise in 5-axis CNC machining, Ethereal Machines ensures that drones are high-performing, robust, and economically viable.

Key Challenges in Drone Manufacturing

Weight Reduction Without Compromising Strength

One of the most critical challenges in drone manufacturing is achieving significant weight reduction without compromising the structural integrity and strength of the drone. Drones must be lightweight to maximize flight efficiency and battery life, but they also need to withstand various stresses and environmental conditions. This delicate balance between weight and strength is crucial for optimal performance.

Advanced materials such as carbon fiber and titanium offer high strength-to-weight ratios. Carbon fiber is particularly favored for its lightweight properties and exceptional strength, making it ideal for constructing drone frames and components. Titanium, although slightly heavier, provides unparalleled strength and corrosion resistance, ensuring the drone’s durability in harsh environments.

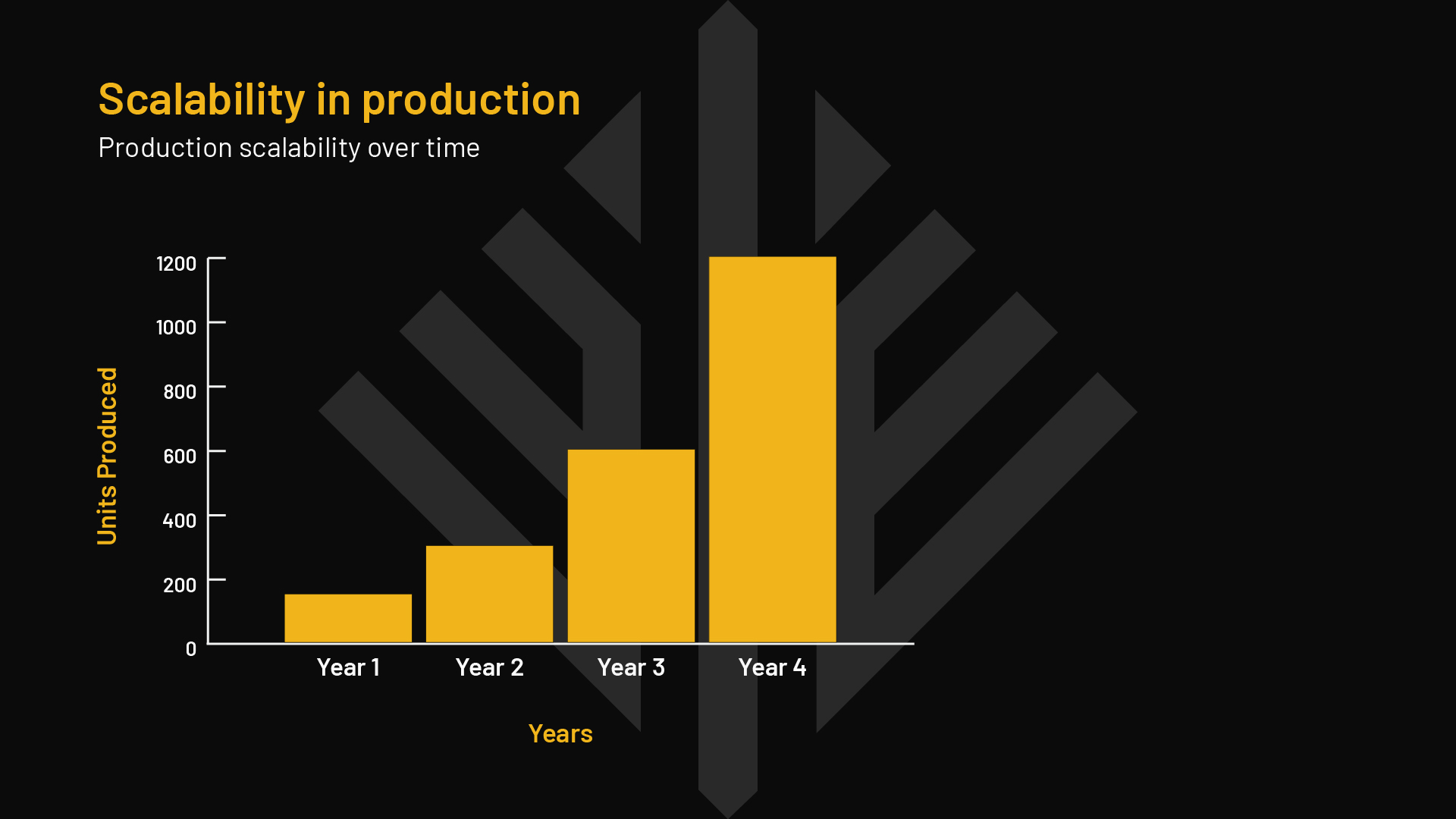

Scalability in Production

As the demand for drones continues to surge, manufacturers face the challenge of scaling production without compromising quality. Ethereal Machines addresses this by implementing state-of-the-art manufacturing processes and technologies that ensure consistency and precision at scale.

The use of 5-axis CNC machining is a cornerstone of Ethereal Machines’ approach. This technology allows for the production of complex components with high precision, reducing the need for multiple setups and manual interventions. This accelerates the production process and ensures that each element meets stringent quality standards.

Cost-Efficiency

Manufacturing drones cost-effectively is essential to making the technology accessible and sustainable. Ethereal Machines employs various strategies to achieve cost-efficiency, including optimizing manufacturing workflows and reducing material waste.

By leveraging precision machining and automation, Ethereal Machines minimizes labor costs and material usage. The integration of advanced software and machinery ensures that each production step is optimized for efficiency, leading to significant cost savings.

Ethereal Machines' Solutions

Ethereal Machines’ commitment to precision and customization sets them apart in the drone manufacturing industry. Our expertise in 5-axis CNC machining enables the production of highly intricate components with unmatched accuracy. This level of precision is crucial for the performance and reliability of drones, particularly in applications that demand exacting standards.

The company’s ability to customize components to meet specific client requirements further enhances its value proposition. Whether it’s a unique design feature or a particular choice of material, Ethereal Machines works closely with clients to deliver tailored solutions that meet their precise needs.

Industry Data and Insights

Data from the EY-FICCI drone report underscores the rapid growth and potential of the drone industry. The global drone market is driven by advancements in technology and the increasing adoption of drones across various sectors. This growth presents significant opportunities for manufacturers like Ethereal Machines to innovate and lead the market.

Potential Applications of Drones

Agriculture

Construction

Public Safety

Conclusion

The challenges of drone manufacturing are significant, but with the right expertise and technology, they can be effectively addressed. Ethereal Machines is at the forefront of this effort, leveraging its precision machining and customization capabilities to produce high-quality, reliable drones. As the drone industry continues to grow, Ethereal Machines is well-positioned to lead the market, offering innovative solutions that meet the evolving needs of various sectors.

For more information or to explore partnership opportunities, contact Ethereal Machines and discover how their cutting-edge manufacturing techniques can benefit your business.

<span data-metadata=""><span data-metadata=""><span data-buffer="">MAAS

Machining As A Service

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 1651