Exploring the World of CMM in CNC Machining

Precision is paramount in the world of manufacturing and engineering. At the heart of this precision-driven universe lies the Coordinate Measuring Machine (CMM), a device that has become indispensable in the realms of quality control and parts fabrication. This blog embarks on an explorative journey into the world of CMMs, delving into their components, uses, and the significant role they play in the constantly evolving CNC industry.

CMMs, with their roots tracing back to the mid-20th century, have undergone remarkable evolution. Initially conceived to measure complex geometries with high precision, these machines have adapted over the years, aligning with technological advancements and changing industry needs. Today, they stand as a cornerstone in manufacturing, offering unparalleled accuracy in the measurement of the physical geometrical characteristics of an object.

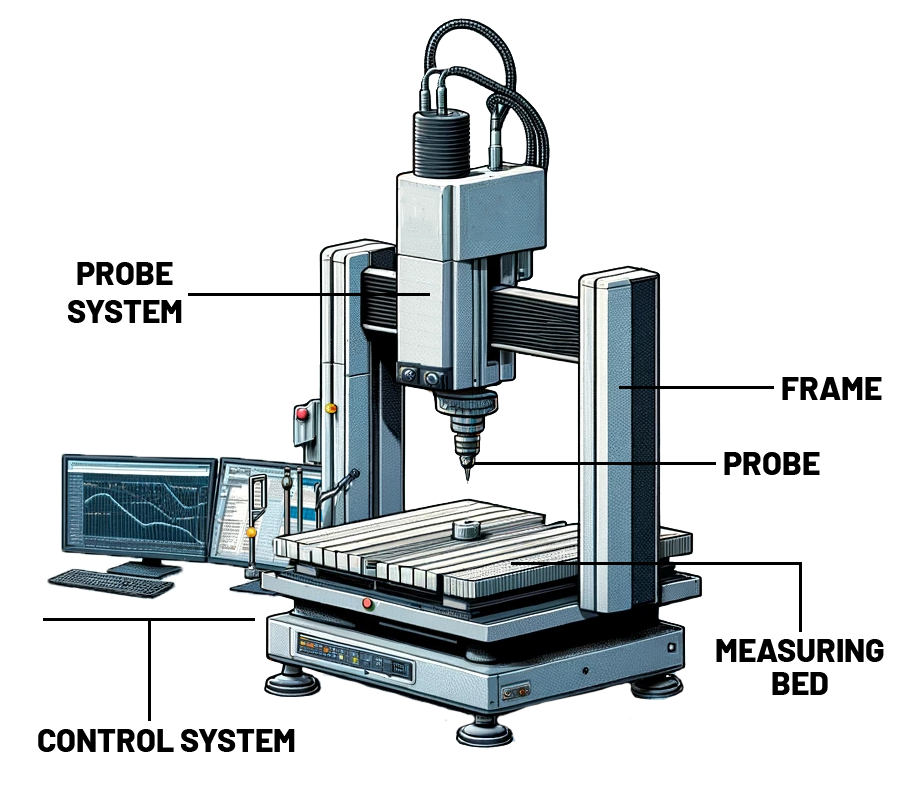

Components of CMM

Core Components of a CMM:

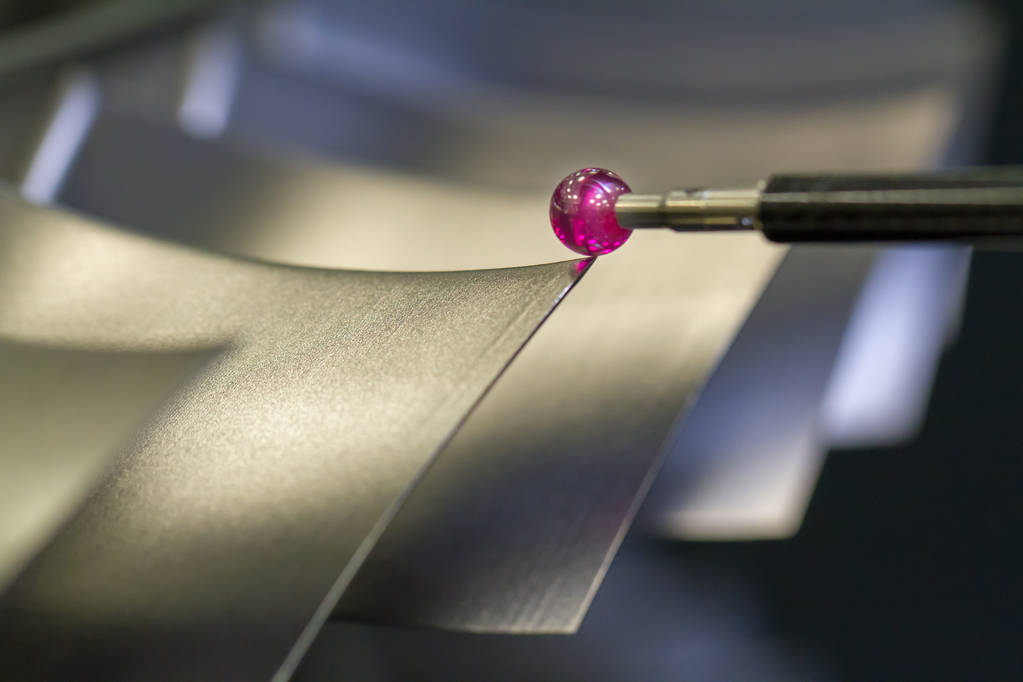

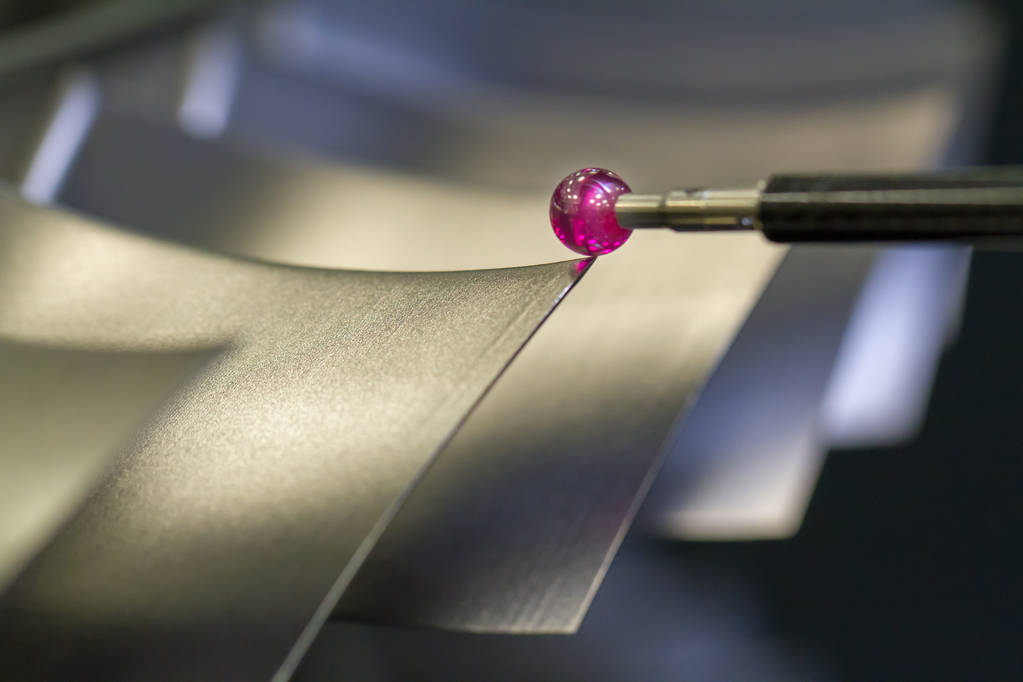

- Probing System: Tactile or non-contact, gathers dimensional data from object surfaces, crucial for accurate data acquisition.

- Measuring Table: Often made of granite, it provides stability and temperature resistance, and serves as the base for measurement.

- Sophisticated Software: Processes and interprets data, converts it into metrics and visual representations, and integrates with CAD programs.

Additional Components and Features:

- Control System: Manages probing system movement and positioning, and ensures precision.

- Data Analysis Tools: Uses advanced algorithms for data analysis, and compensates for anomalies.

- Calibration Equipment: Maintains CMM accuracy, and requires regular calibration against standards.

- Frame or Structure: Supports CMM components, designed for rigidity and minimal thermal expansion.

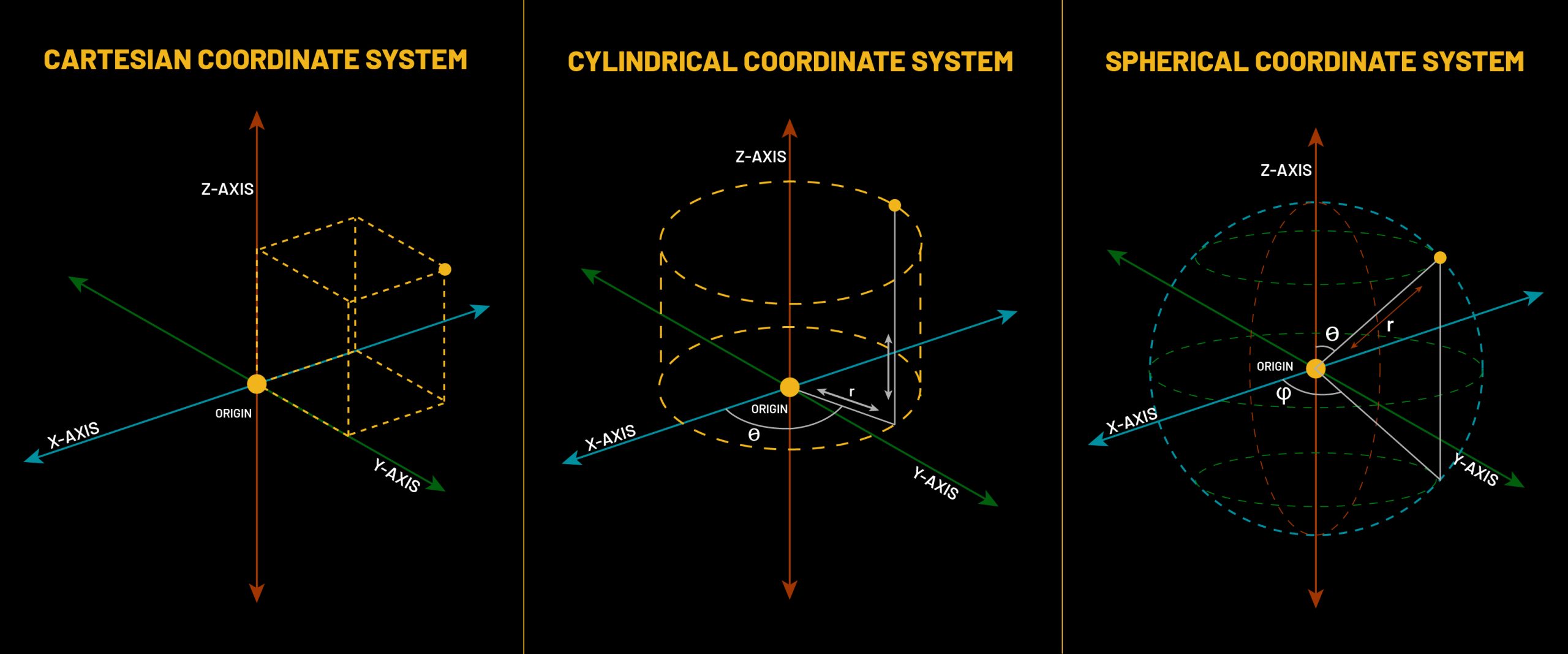

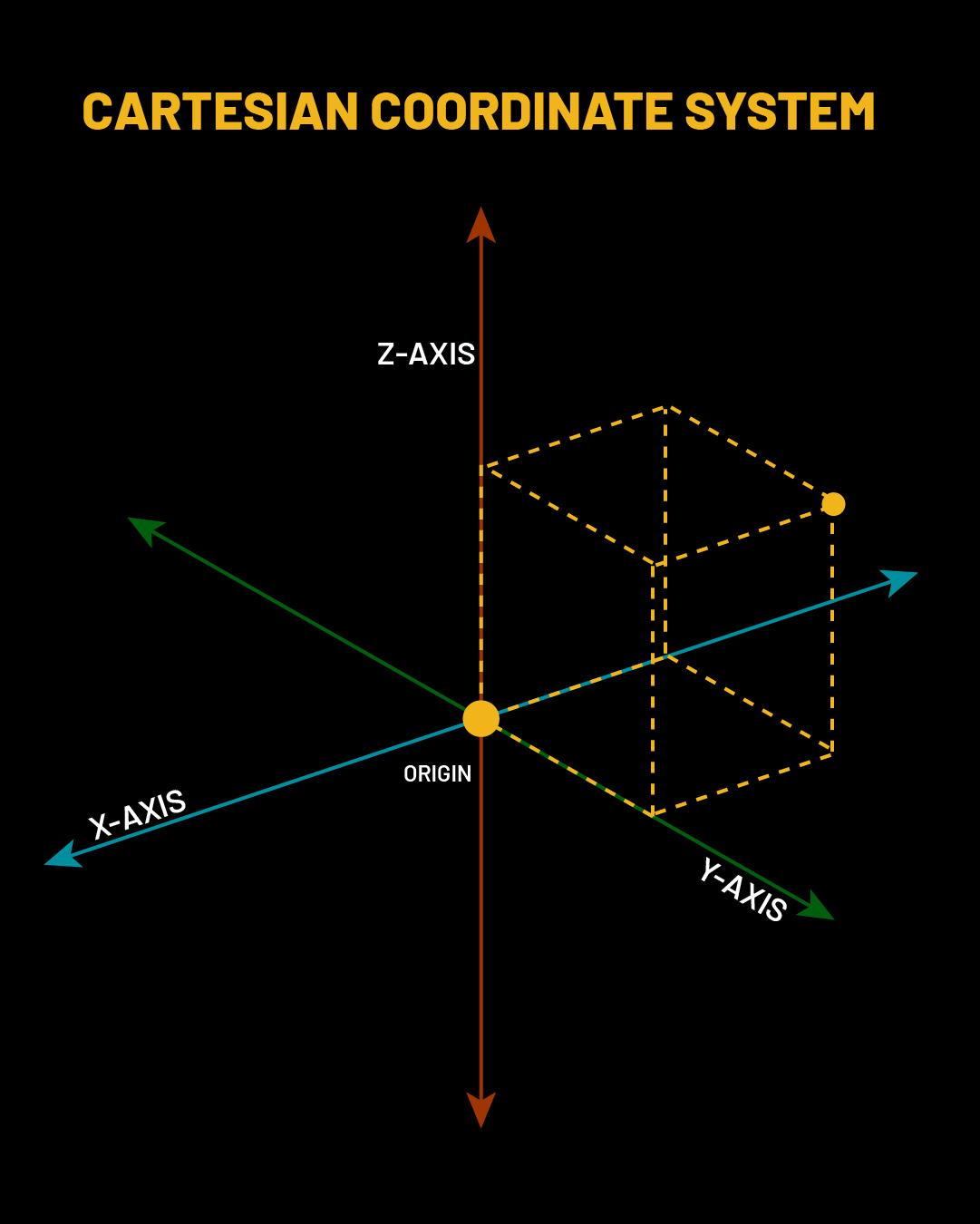

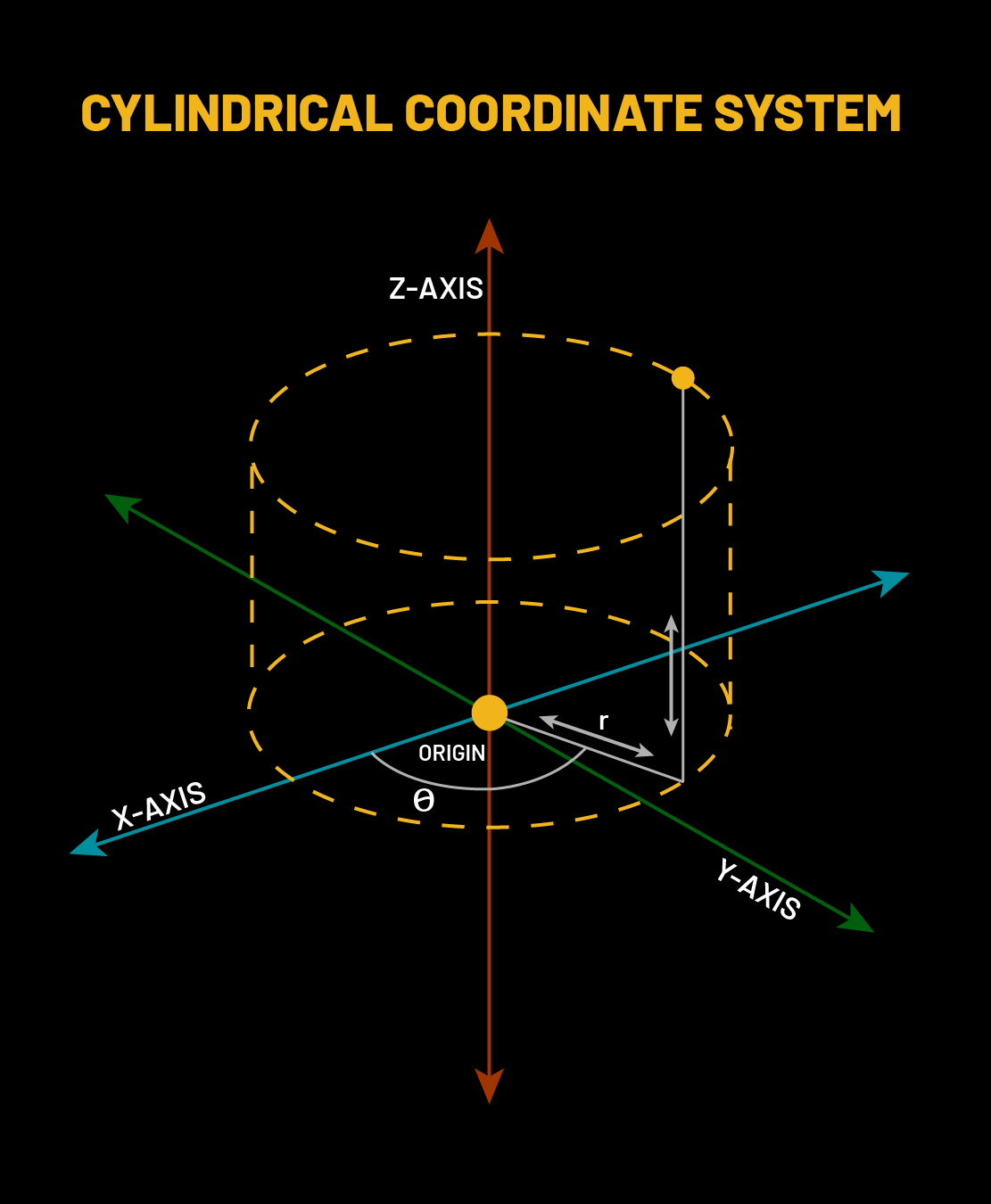

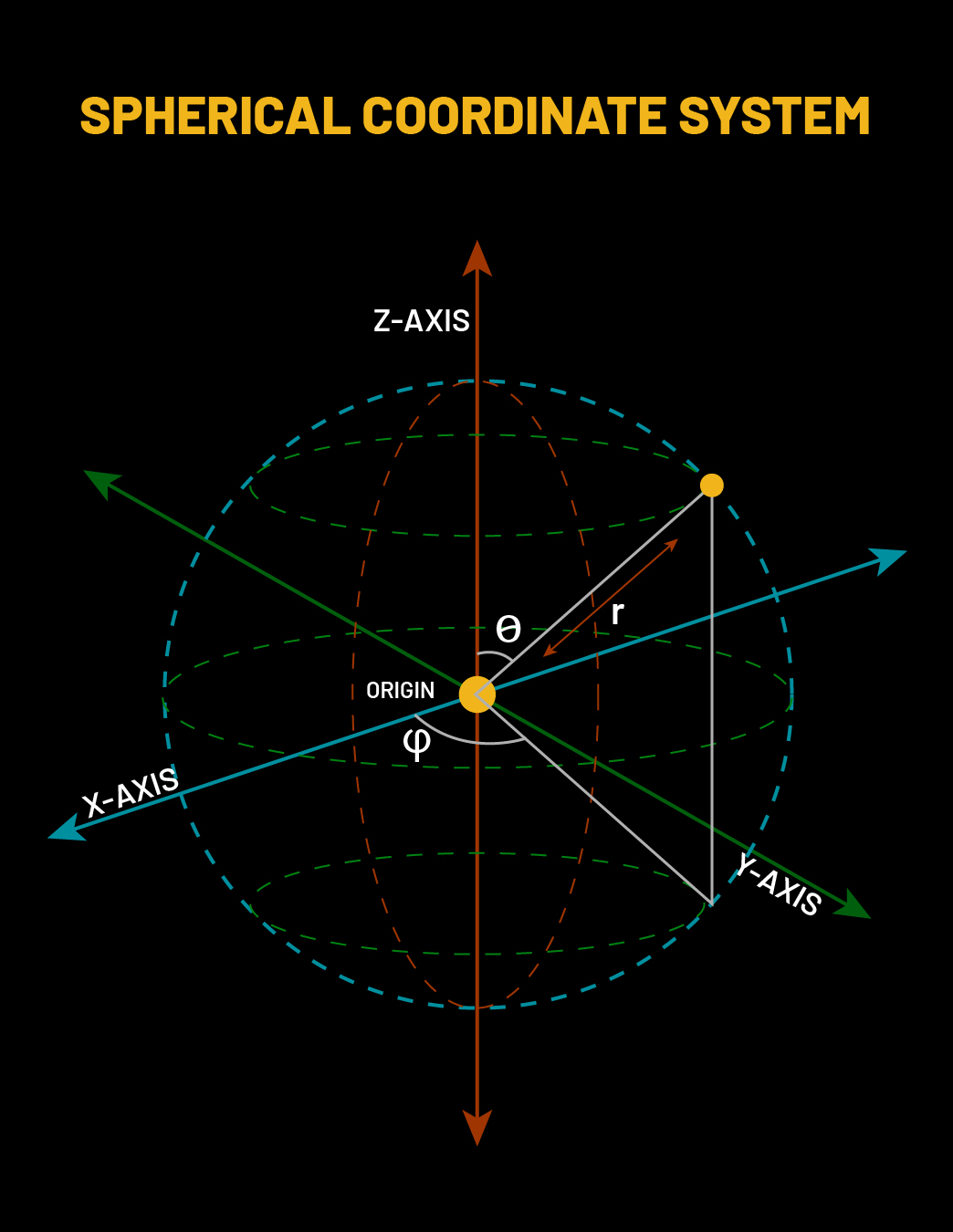

CMM and Different Coordinate Systems:

CMMs are renowned for their ability to measure an array of coordinate systems with high precision. This includes:

- Cartesian Coordinate System: The most common, featuring X, Y, and Z axes for 3D spatial measurement.

- Polar Coordinate System: Utilized for cylindrical objects where measurements are taken in radial distances and angles.

- Spherical Coordinate System: Ideal for spherical objects, measuring angles and distance from a central point.

These systems enable CMMs to adapt to a wide range of geometric measurements, from simple dimensions to complex shapes

CMM and Different Coordinate Systems:

CMMs are renowned for their ability to measure an array of coordinate systems with high precision. This includes:

Cartesian Coordinate System: The most common, featuring X, Y, and Z axes for 3D spatial measurement.

Polar Coordinate System: Utilized for cylindrical objects where measurements are taken in radial distances and angles.

Spherical Coordinate System: Ideal for spherical objects, measuring angles and distance from a central point.

These systems enable CMMs to adapt to a wide range of geometric measurements, from simple dimensions to complex shapes

CMM Uses in CNC Machining

The uses of Coordinate Measuring Machines (CMMs) in CNC machining are multifaceted and crucial for maintaining high standards of precision and quality. Here are some key points:

- Precision in Manufacturing: CMMs are integral in CNC machining to ensure that parts are produced according to specifications. This is essential in industries where even the slightest deviation can lead to product failure or safety issues.

- Quality Assurance: By accurately measuring the dimensions of CNC machined parts, CMMs validate that the products adhere to the stringent tolerances required. This step is vital in guaranteeing the quality and reliability of the final product.

- Reverse Engineering Capabilities: CMMs assist in reverse engineering processes. They can accurately measure a physical part and help create detailed 3D models and technical drawings, which are crucial for replicating or improving existing designs.

- Dimensional Analysis: Through precise measurement, CMMs provide crucial data for dimensional analysis, ensuring every aspect of a machined part is as designed.

- Automotive Industry Applications: In automotive manufacturing, where each part must fit perfectly and function seamlessly, CMMs are indispensable for verifying dimensions and fit.

- Aerospace Industry Significance: The aerospace industry relies heavily on CMMs to ensure the safety and efficacy of components. Given the high stakes involved in aerospace engineering, the precision provided by CMMs is non-negotiable.

The accompanying infographic visually represents these points, highlighting the importance of CMMs in CNC machining.

Latest Trends Impacting the CMM and CNC Industry

Automation and AI Integration:

- CMMs now feature advanced, automated capabilities.

- AI algorithms optimize measurement paths and processes.

- This leads to reduced manual intervention, enhanced precision, and increased efficiency.

Advances in Speed and Precision:

- The demand for higher speed and precision in CNC machining is rising.

- Modern CMMs are designed to operate at these increased speeds without sacrificing accuracy.

- This aligns with the demanding requirements of current manufacturing processes.

Latest Trends Impacting the CMM and CNC Industry

Automation and AI Integration:

- CMMs now feature advanced, automated capabilities.

- AI algorithms optimize measurement paths and processes.

- This leads to reduced manual intervention, enhanced precision, and increased efficiency.

Advances in Speed and Precision:

- The demand for higher speed and precision in CNC machining is rising.

- Modern CMMs are designed to operate at these increased speeds without sacrificing accuracy.

- This aligns with the demanding requirements of current manufacturing processes.

The Vital Role of CMMS in Enhancing CMM Efficiency

Maintenance Scheduling and Predictive Maintenance

Data Management and Lifecycle Oversight

Cost Management and Regulatory Compliance

Cost management is another facet where CMMS proves indispensable. By providing detailed insights into maintenance-related expenditures, CMMS helps optimize the cost-effectiveness of CMM operations. Additionally, in industries where compliance with stringent standards is non-negotiable, CMMS ensures that CMMs are maintained and calibrated as per regulatory requirements, thereby upholding compliance.

Advanced CMMS Features Elevating CMM Operations

Seamless System Integration

Improved Safety and User Experience

Training and Knowledge Sharing

CMMS also facilitates the development of comprehensive training programs for maintenance staff, ensuring they are well-versed in the best practices for CMM upkeep. Moreover, it serves as a knowledge repository, offering easy access to troubleshooting guides and maintenance instructions, which is invaluable for efficient CMM management.

The relationship between CMM and CMMS epitomizes the perfect blend of precision measurement and efficient management. This integration not only enhances the operational efficiency of CMMs but also aligns with the broader goals of cost-effectiveness, safety, and compliance in the manufacturing sector. As technology continues to evolve, this symbiotic relationship is set to become even more integral to the world of precision manufacturing.

Benefits of CMMs

Unmatched Precision and Efficiency

• Precision and Speed That Translates to Efficiency

Cost-Effective Manufacturing

• Minimizing Errors and Waste

Seamless Integration with Technology

• CAD/CAM Systems Compatibility

CMMs seamlessly integrate with CAD/CAM systems, streamlining the design-to-production workflow. This integration allows for real-time adjustments based on measurement feedback, enhancing the overall manufacturing process.

Beyond Measurements

• Customer Satisfaction and Material Versatility

CMMs contribute to producing high-quality products, leading to increased customer satisfaction. They are also adept at handling diverse materials and intricate designs, adding versatility to their manufacturing capabilities.

Data-Driven Manufacturing

• Analytical Insights for Improvement

Conclusion

CMMs have revolutionized the way measurements are conducted in the CNC industry, bringing unprecedented levels of precision and efficiency. Their evolution has mirrored that of CNC technology, growing more sophisticated and capable. As we look to the future, the continued integration of advanced technologies promises to enhance the capabilities of CMMs further.

In the fast-paced manufacturing world, where accuracy is not a luxury but a necessity, CMMs are a testament to human ingenuity and the relentless pursuit of perfection. They are not just tools but partners in the quest for precision, playing a crucial role in driving the CNC industry forward.

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 763