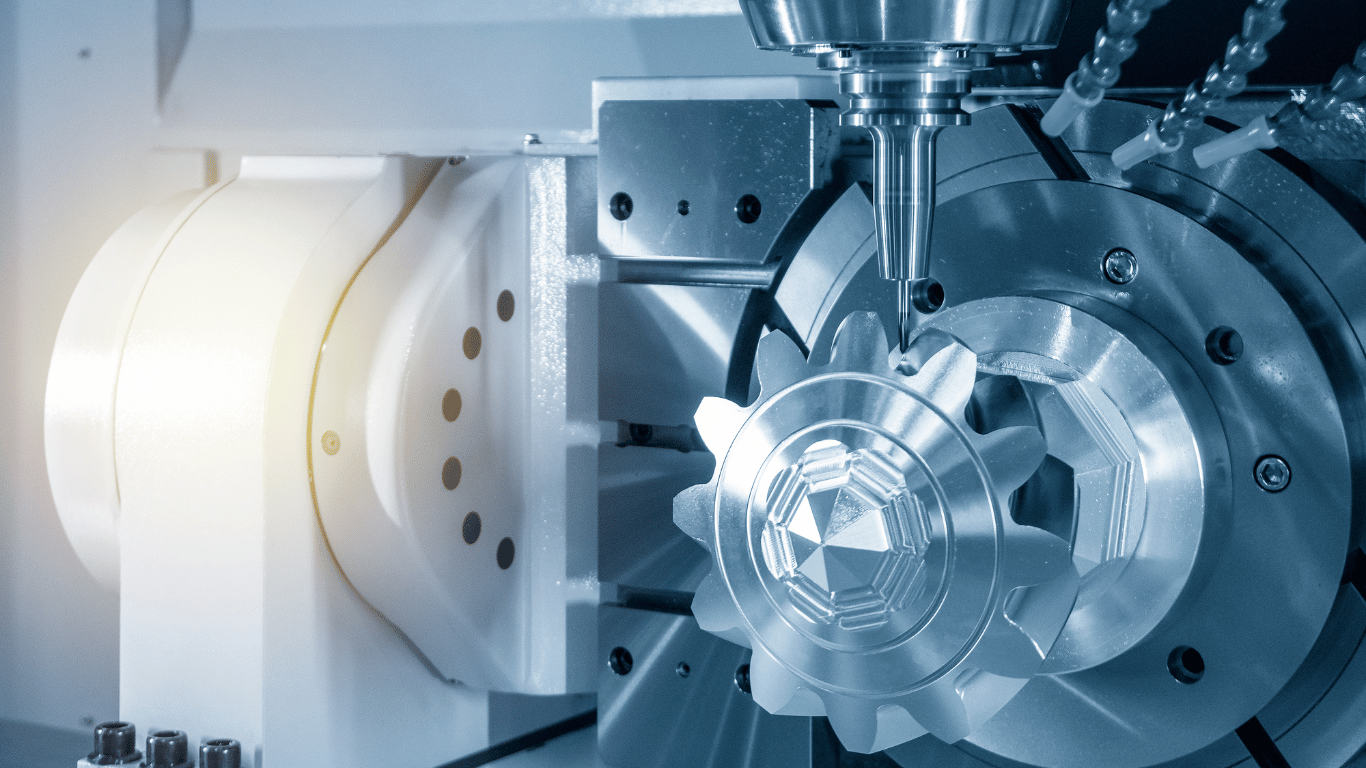

In the world of manufacturing, efficiency and precision are crucial when it comes to creating complex parts and components. With the ever-increasing demand for high-quality products in various industries, it is essential for manufacturers to utilize innovative methods for producing these items. One such technique that has gained widespread recognition in recent years is the 5-Axis Computer Numerical Control (CNC) machining. This technology can be used in many areas of modern manufacturing, from aerospace engineering to the medical field, thanks to its unparalleled versatility.

In this blog, we will explore the fascinating world of 5-Axis CNC machining and how it benefits various industries in modern manufacturing. So, let’s dive in and discuss the wonders of this technological marvel, which is quickly transforming the manufacturing landscape as we know it.

What is 5-Axis CNC Machining?

In simple terms, 5-Axis CNC machining refers to the process of manufacturing complex parts and components using a computerized machine that can move along five different axes. This allows the machine tool to create intricate and precise cuts on the workpiece, enabling it to chip away materials in a highly detailed manner. As a result, manufacturers can quickly and accurately produce items with intricate designs and geometries that would have been nearly impossible through traditional machining methods.

The 5-Axis CNC machining process comprises three linear axes and two rotational axes, which means that the machine tool can move from side to side, up and down, and in and out, while also tilting and rotating the workpiece. This increased freedom of movement allows manufacturers to create sophisticated parts in less time and with greater precision, all while minimizing the potential for human error.

Revenue Forecast

Revenue forecasts for the 5-axis CNC machining market are expected to show an upward trend, driven by the growing demand from various industries for quality, precision, and efficiency in manufacturing. According to a report by Market Research Future, the 5-axis CNC machine market is projected to reach USD 4.43 billion by 2023, growing at a CAGR of 6.52% during the forecast period. The report cites the growing demand from the automotive, aerospace, and medical industries, as well as the advancement of technology used in 5-axis CNC machining, as the major factors driving the growth of this market. With increasing demand for complex, sophisticated, and precise components, the 5-Axis CNC machining market is expected to expand rapidly, opening up new opportunities for manufacturers and businesses across automotive, aerospace & medical sectors.

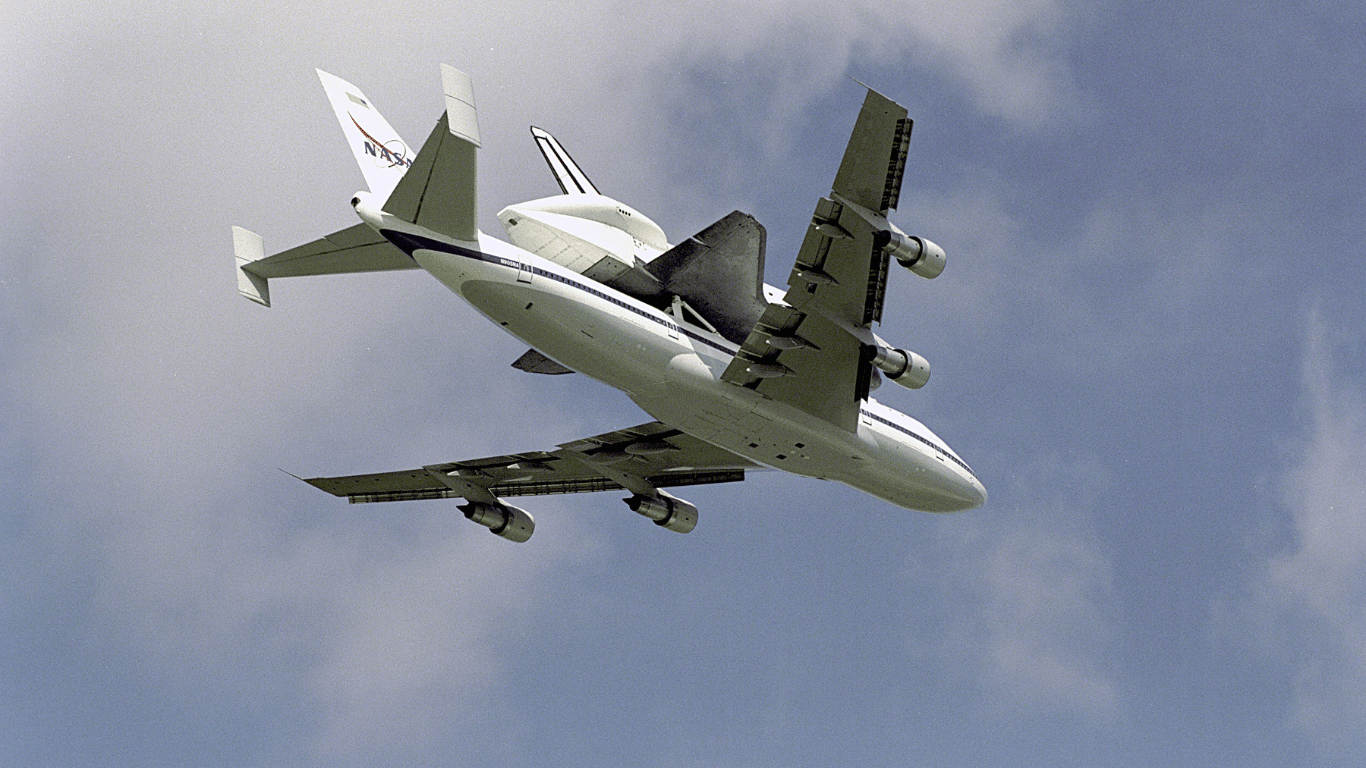

Aircraft and spacecraft design has always necessitated the use of high-quality components that can withstand extreme stress and conditions. With 5-Axis CNC machining, aerospace engineers can manufacture lightweight yet sturdy parts that meet the stringent requirements of this high-stakes industry. Components such as turbine blades, airfoils, and engine casings can be manufactured with absolute precision, ensuring the highest level of performance and safety for their applications.

In addition to producing reliable and lightweight components, 5-axis CNC machining also enables aerospace manufacturers to create more fuel-efficient and environmentally-friendly aircraft. By employing this state-of-the-art technology, engineers can continually refine and improve designs, which in turn, results in financial savings and a reduced impact on the environment.

Medical Industry: Custom Implants and Surgical Tools

Like aerospace engineering, the medical industry also necessitates the use of cutting-edge technology for producing precise, safe, and effective equipment. As such, 5-axis CNC machining has become a staple in the manufacturing of custom implants, prosthetics, and surgical tools.

Implants, such as hip and knee replacements, must be specifically tailored to the individual patient to ensure a proper fit and function. 5-Axis CNC machining allows medical manufacturers to create customized implants that precisely match a patient’s unique anatomy. This degree of personalization leads to better outcomes and significantly reduces recovery times.

Similarly, 5-Axis CNC machining is vital for producing complex surgical tools and instruments that are crucial for performing complex, life-saving operations. Surgeons can rely on these high-quality, precision-engineered tools to execute their tasks with confidence and accuracy, ultimately providing the best care possible for their patients.

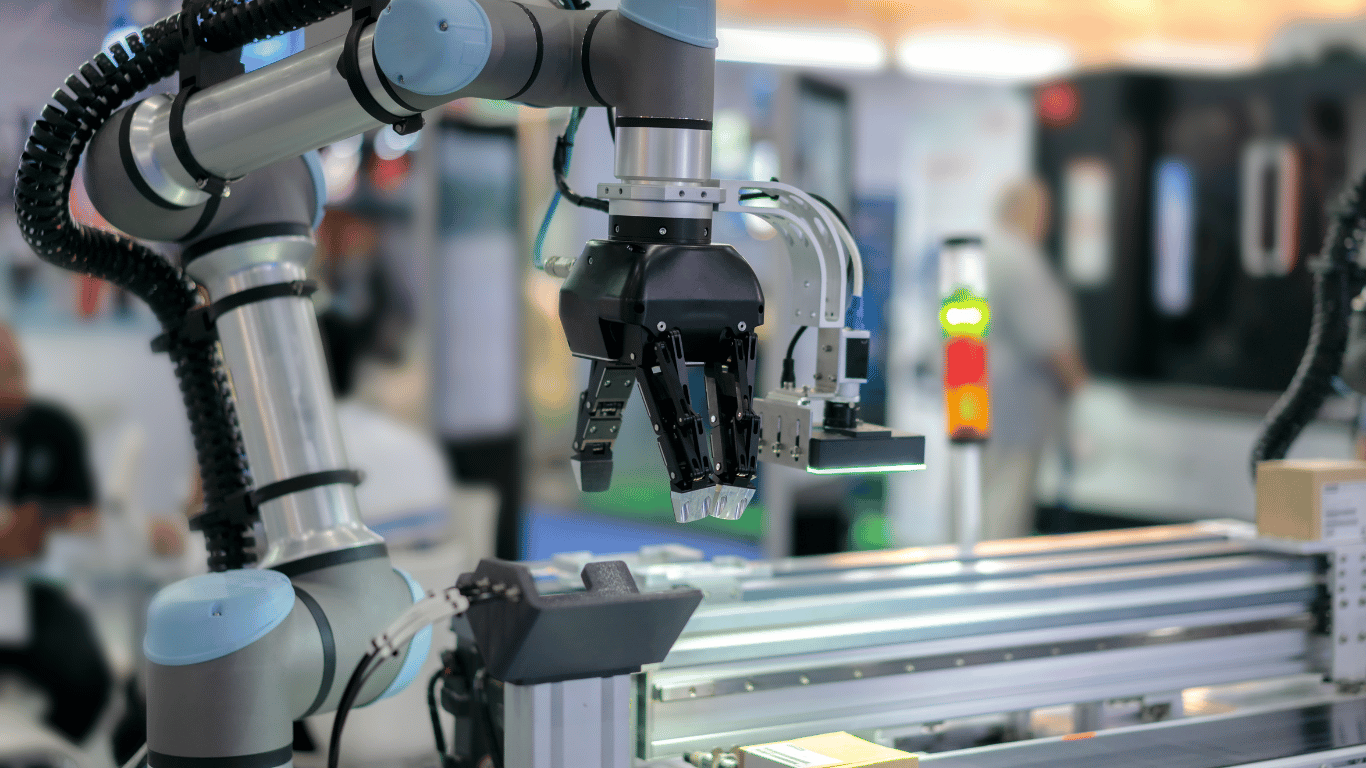

Automotive Manufacturing: Enhanced Design and Performance Capabilities

5-axis CNC machining has also revolutionized the automotive industry by allowing manufacturers to create high-performance engine components and aesthetically pleasing car designs. With this technology, automobile makers can produce engine parts that exhibit enhanced fuel efficiency, reduced engine noise, and increased power output. Additionally, 5-axis CNC machining enables the creation of intricate and sophisticated car designs that were once thought to be impossible.

Conclusion

Views: 379