Industry 4.0 and IoT Transforming the CNC Machining Landscape

In the intricate dance of modern manufacturing, two acronyms have taken the lead: IoT and CNC. The Internet of Things (IoT) represents an interconnected reality where devices communicate and operate with minimal human intervention. Computer Numerical Control (CNC), on the other hand, has long been the backbone of precision and automation in manufacturing. The fusion of these technologies is not just an incremental step forward; it’s a surge reshaping the industry’s landscape.

This surge is not merely about adopting new technologies but about the transformation they bring to the manufacturing floor. As we delve into the heart of this topic, we will explore the symbiotic relationship between IoT and CNC, and why this integration is pivotal in modern manufacturing trends. The journey from standalone machines to intelligent, networked systems is a testament to human ingenuity and the relentless pursuit of efficiency.

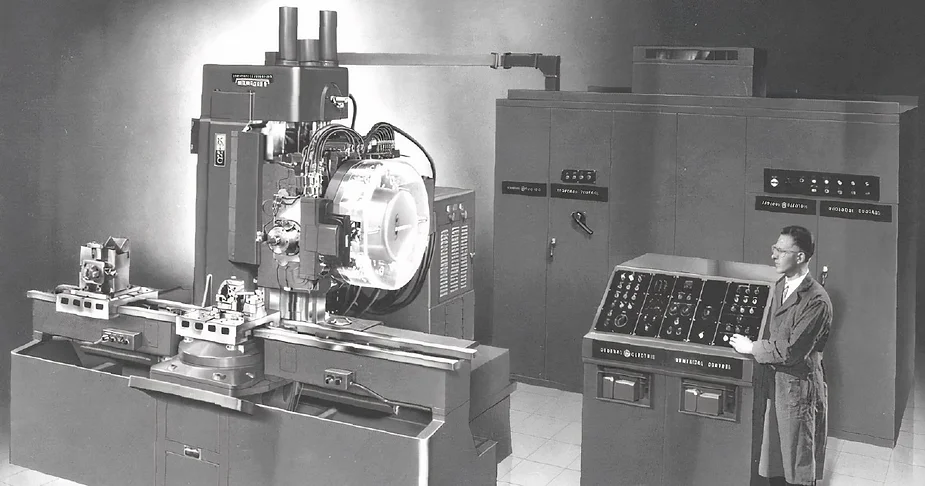

The Evolution of CNC Technology

Traditionally, CNC machines have been lauded for their precision and ability to produce complex parts. However, they operated in silos, with limited ability to adapt to changing conditions or to communicate with other systems. This isolation meant that even as they produced with exactness, there was a gap—a gap in efficiency, predictive maintenance, and real-time adaptability.

The introduction of IoT into the realm of CNC began as a ripple that has since swelled into a significant wave of change. Initial impacts were seen in the ability to monitor machines remotely, but this was just the prelude to a far more extensive symphony of advancements that IoT would bring to CNC technology.

IoT Advancements in CNC

The integration of IoT into CNC machinery has been a game-changer in the manufacturing industry. This section will explore the key advancements that IoT has brought to CNC technology and how they translate into tangible benefits for manufacturers.

Real-time Monitoring and Data Analysis

The cornerstone of IoT’s impact on CNC is the ability to monitor operations in real-time. Sensors embedded in CNC machines collect a myriad of data points – from operational temperatures to vibration patterns. This data is then analyzed to provide insights into the machine’s performance, allowing for immediate adjustments and enhanced control over the manufacturing process. The result is a significant reduction in errors and an increase in the overall quality of the output.

Predictive Maintenance and Machine Learning

One of the most significant advantages of IoT in CNC is predictive maintenance. By analyzing data trends, IoT systems can predict when a machine part might fail or when maintenance is required. This foresight minimizes unexpected downtime, ensuring that the manufacturing process runs more smoothly and efficiently. Machine learning algorithms further refine this process by learning from historical data, continuously improving the accuracy of their predictions over time.

Enhanced Precision and Automation through IoT

IoT doesn’t just allow for monitoring; it enables a higher level of precision and automation. By constantly feeding back data to the CNC system, machines can adjust their operations for optimal performance. This self-regulation not only enhances precision but also allows for a higher degree of automation. As a result, CNC machines can operate with minimal human intervention, even adjusting to new designs and specifications with ease.

Case Studies of IoT-driven CNC Efficiency Improvements

Several case studies highlight the efficiency improvements brought about by IoT in CNC. For instance, a manufacturer might use IoT to reduce the energy consumption of their CNC machines by optimizing their operation schedules based on real-time demand and workload data. Another case study might showcase a factory that has significantly reduced waste material by using IoT-enabled precision monitoring, ensuring that each cut and mold is within micrometers of the specified dimensions.

Industry 4.0 and CNC

The term Industry 4.0 signifies the fourth industrial revolution, characterized by a fusion of technologies that blur the lines between the physical, digital, and biological spheres. CNC machines, once considered the pinnacle of industrial automation, are now being redefined within the context of Industry 4.0.

The Role of CNC Machines in the Fourth Industrial Revolution

CNC machines have evolved from standalone units to integral components of a connected manufacturing ecosystem. In Industry 4.0, these machines are not just tools for cutting and shaping but are intelligent systems capable of self-optimization and decision-making. They are nodes in a vast network of production intelligence, contributing to and benefiting from the collective knowledge of the entire manufacturing process.

Integration with Other Industry 4.0 Technologies

The true potential of CNC in Industry 4.0 is unlocked when integrated with other technologies such as AI, robotics, and additive manufacturing. AI algorithms can enhance CNC machine learning capabilities, leading to more efficient operations. Robotics can work in tandem with CNC machines for material handling, loading, and unloading, which streamlines the workflow. Additive manufacturing, or 3D printing, can complement CNC machining for complex components, allowing for more creative and flexible design possibilities.

The Transformation of Manufacturing Workflows

The integration of IoT with CNC machines is transforming manufacturing workflows. Data-driven insights enable more agile production methods, rapid prototyping, and dynamic response to market demands. The traditional linear production line is giving way to a more flexible, modular, and scalable approach. This transformation is not just about efficiency; it’s about resilience and the ability to adapt to new challenges rapidly.

Benefits of IoT-Driven CNC Machines

The integration of IoT with CNC machines has brought forth a plethora of benefits that resonate throughout the entire manufacturing process. These benefits not only enhance productivity but also foster a more sustainable and responsive manufacturing environment.

Increased Productivity and Efficiency

IoT-driven CNC machines streamline the manufacturing process, leading to a significant uptick in productivity. With real-time monitoring, these machines can operate at optimal speeds, manage resources more efficiently, and reduce the time it takes to switch from one production batch to another. The ability to preemptively identify and address potential issues before they result in downtime contributes to a more efficient production line.

Reduction in Downtime and Operational Costs

Downtime is the adversary of productivity. IoT-enabled predictive maintenance ensures that CNC machines are serviced before breakdowns occur, dramatically reducing unplanned downtime. Moreover, the operational costs associated with machine failure and maintenance are significantly lowered, as IoT systems facilitate a more targeted and efficient approach to servicing.

Improved Safety and Working Conditions

The safety of the manufacturing floor is paramount, and IoT-driven CNC machines contribute to a safer work environment. By continuously monitoring machine conditions, IoT systems can detect potential safety hazards and trigger alerts before they pose a risk to workers. Additionally, with machines taking on more autonomous roles, human operators are less exposed to dangerous tasks, further improving working conditions.

Customization and Flexibility in Manufacturing

The modern market demands customization, and IoT-equipped CNC machines are well-suited to meet this need. They can quickly adjust to new specifications and designs, allowing manufacturers to offer a wider range of customized products without sacrificing efficiency. This flexibility is a competitive edge in a market that values tailored solutions over one-size-fits-all products.

Challenges and Considerations

While the integration of IoT with CNC machinery heralds a new era of manufacturing prowess, it also brings to the fore several challenges and considerations that must be navigated carefully.

Security Concerns with IoT-Enabled Machines

The modern market demands customization, and IoT-equipped CNC machines are well-suited to meet this need. They can quickly adjust to new specifications and designs, allowing manufacturers to offer a wider range of customized products without sacrificing efficiency. This flexibility is a competitive edge in a market that values tailored solutions over one-size-fits-all products.

Investment and Cost-Benefit Analysis

Adopting IoT technology in CNC machines requires significant investment. Manufacturers must consider the upfront costs of upgrading equipment, implementing new software systems, and training personnel. A thorough cost-benefit analysis is essential to determine the long-term savings and increased revenue that IoT integration can deliver, ensuring that the investment is justified.

Skill Gap and the Need for Workforce Training

The sophistication of IoT-driven CNC machines necessitates a workforce that is skilled in both traditional machining and modern digital technologies. This dual requirement can exacerbate the existing skill gap in the manufacturing sector. Companies must commit to training their employees, not only to operate these advanced machines but also to analyze and act on the data they provide.

Ensuring Data Privacy and Compliance with Regulations

With the vast amounts of data generated by IoT devices, manufacturers must navigate the complexities of data privacy and regulatory compliance. This includes managing the storage, processing, and sharing of data following legal requirements, which can vary significantly across different regions and jurisdictions.

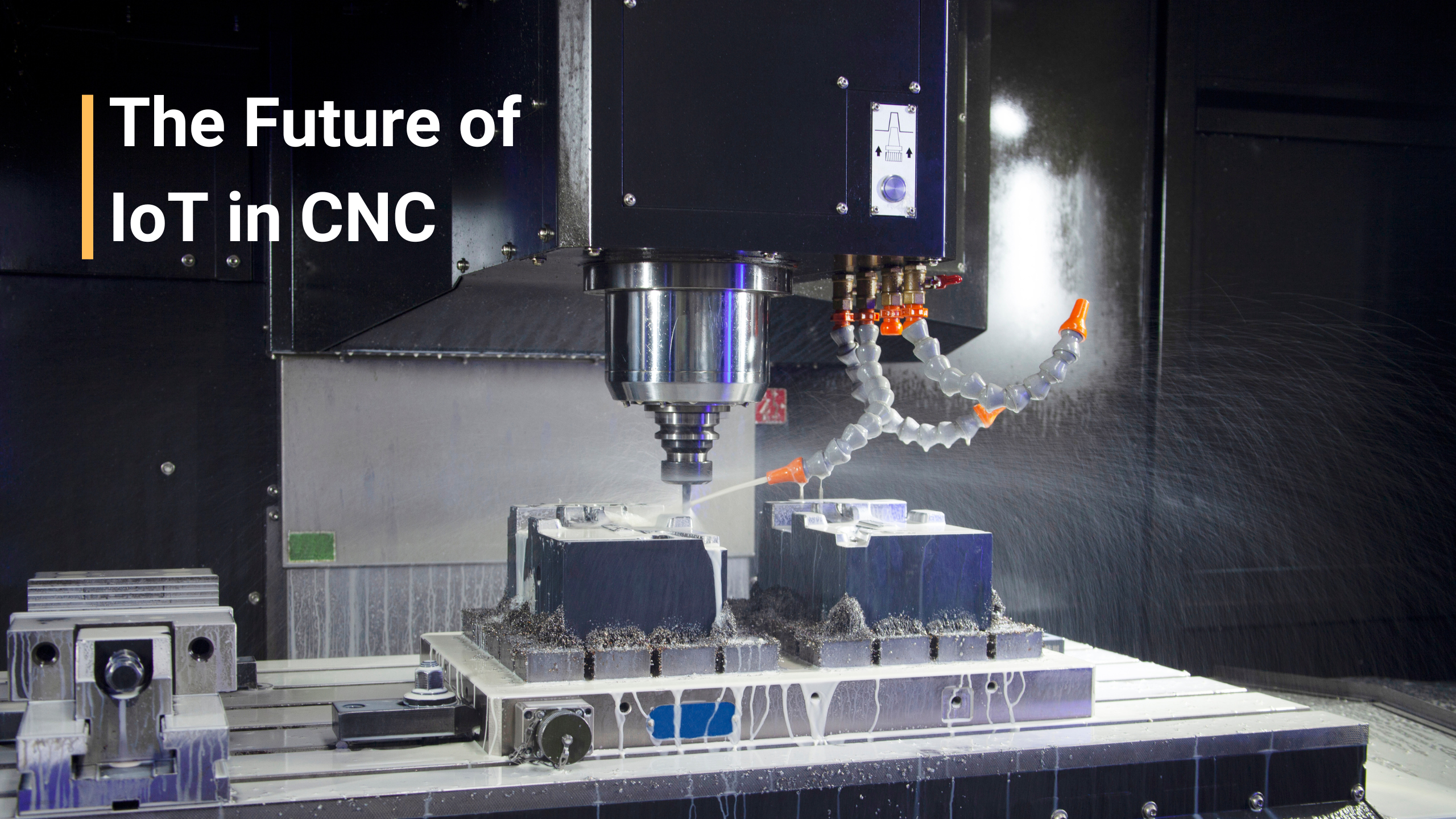

The Future of IoT in CNC

As we stand on the cusp of new developments in manufacturing technology, the future of IoT in CNC promises even more profound changes to the industry. This section will explore the emerging trends and technologies that are poised to further advance CNC capabilities and the potential impact on global manufacturing and economies.

Emerging Trends and Future Technologies

The future will likely see the advent of more sophisticated forms of machine learning and AI integrated into CNC machines, enabling them to make more complex decisions and further improve manufacturing processes. The integration of augmented reality (AR) for machine maintenance and training could also enhance the capabilities of technicians, leading to even greater efficiencies.

Another trend is the development of more advanced sensors and machine components that can self-diagnose and even self-repair, pushing the boundaries of predictive maintenance. Additionally, the rise of 5G technology is expected to significantly improve the speed and reliability of machine-to-machine communication, facilitating more responsive and flexible manufacturing systems.

Predictions for IoT's Role in Advancing CNC Capabilities

As IoT technology continues to evolve, it is predicted that CNC machines will become even more autonomous, and capable of handling a wider range of tasks with minimal human intervention. This could include automatic adjustment of cutting parameters in response to sensor data or the ability to switch between different manufacturing tasks without manual reprogramming.

Potential Impact on Global Manufacturing and Economies

The implications of these advancements are far-reaching. On a global scale, IoT-driven CNC technology could lead to the creation of more high-tech jobs and a shift in the skills required in the manufacturing workforce. Economies could become more efficient as production times and costs decrease, and the ability to rapidly adapt to market changes could become a new competitive advantage for manufacturers.

Conclusion

The surge in the CNC industry driven by IoT integration is not just a fleeting trend; it is a fundamental shift in how manufacturing is approached. This blog has explored the evolution of CNC technology, the advancements brought about by IoT, and the benefits and challenges of this integration. We have seen through case studies how businesses have reaped tangible rewards from embracing these technologies.

As we look to the future, it is clear that the trajectory of IoT in CNC manufacturing is set to continue its upward course. For businesses, the importance of embracing these technological advancements cannot be overstated. Those who do will likely find themselves at the forefront of the next industrial wave, equipped to meet the demands of a rapidly evolving marketplace.

The convergence of IoT and CNC is more than just a technological upgrade; it is a redefinition of manufacturing possibilities. As we navigate this new wave, the potential for innovation and growth is boundless, promising a future where manufacturing precision, efficiency, and flexibility reach unprecedented levels.

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 1605