Mastering CNC Machining: A Proven Roadmap

The CNC process involves four stages concept, design (CAD), toolpath generation (CAM), and machining. It’s a dance between your imagination and the machine, yielding precise and consistent results. The benefits of CNC machining include precision, efficiency, versatility, and cost-effectiveness, making it invaluable for artists, craftsmen, and industries.

Selecting the right CNC machine requires careful consideration of your needs, budget, space, and desired features. Research, read reviews, and seek expert advice to make an informed decision.

Setting up your CNC machine involves either building one from scratch or purchasing a pre-made model. Ensure you have essential tools, safety gear, and the necessary software. Safety should be a priority, and familiarize yourself with the machine’s operation.

To begin your CNC journey, learn the basics of G-code, calibrate your machine, and start with simple projects. Don’t fear challenges; troubleshooting is part of the learning process. Join online communities, attend workshops, and embrace advanced techniques to continually improve your skills.

What is CNC Machining?

CNC stands for Computer Numerical Control, and it’s a process where a computer program controls the movement of tools and machinery to create precise and intricate designs. So, instead of manually operating machines, you get to sit back and relax while the computer does all the work.

CNC machining has revolutionized the manufacturing industry, allowing for faster production times, superior accuracy, and incredible versatility. With CNC machines, you can create everything from simple shapes to complex 3D designs with ease.

CNC machining is not just for big corporations or genius engineers. It has become more accessible and affordable, making it a viable option for home hobbyists too. So, if you’ve got a bit of space in your garage and a knack for creativity, CNC machining might just be your new favorite hobby.

The Evolution of CNC Machining

CNC machining has come a long way from its exclusive beginnings in the world of manufacturing. It used to be a playground for giant corporations with deep pockets, as massive CNC machines filled expansive factory floors. However, a remarkable transformation has occurred over the years, bringing CNC machining within reach of everyday enthusiasts and small businesses.

Advancements in technology have been a driving force in this evolution. Smaller and more affordable CNC machines have emerged, thanks to innovations in hardware and software. These machines offer precision and versatility, opening doors to a wide range of applications.

The DIY spirit has also played a significant role. Now, with some technical knowledge and basic power tools, individuals can construct their own hobby CNC machines right in their garages. This represents a democratization of CNC technology, empowering anyone with a passion for creating.

Interestingly, the rise of CNC machining shares common ground with 3D printing. Both technologies use similar components such as stepper motors, controllers, and motion guides. In essence, they enable the transformation of creative ideas into physical reality, making it more accessible than ever before.

In the upcoming sections of this blog, we’ll explore the world of CNC machining in more detail. We’ll delve into the different types of CNC machines, uncover how they work, and unveil the incredible possibilities they offer. Whether you’re a seasoned CNC expert or a newcomer intrigued by the world of precision manufacturing, this journey through the evolution of CNC machining promises to be an exciting one. So, buckle up as we navigate the remarkable changes that have revolutionized the way we innovate, create, and build.

Understanding the CNC Process

First, we have the concept and idea stage. This is where your creativity takes flight. Whether you’re envisioning a sleek wooden chair or a complex metal sculpture, this is the moment to let your imagination soar. Think big, dream big, and lay the foundation for your CNC project.

Once your concept is solid, it’s time to dive into the CAD (Computer-Aided Design) process. CAD brings your ideas to life on the digital canvas. Craft intricate 3D models, fine-tune every dimension, and even simulate the look of your final creation. It’s the bridge that connects your imagination to the computer screen.

Now, the spotlight shifts to the CAM (Computer-Aided Manufacturing) process. This is where the true magic unfolds. CAM software translates your meticulously designed model into precise instructions for the CNC machine. It’s the moment when your dreams become reality, as the CNC machine, armed with its cutting tools, transforms raw materials into your masterpiece with astonishing precision.

In essence, CNC machining is an incredible blend of creativity and engineering. So, have fun, push your boundaries, and let your ideas materialize.

Types of CNC Machines

1. CNC Milling Machines

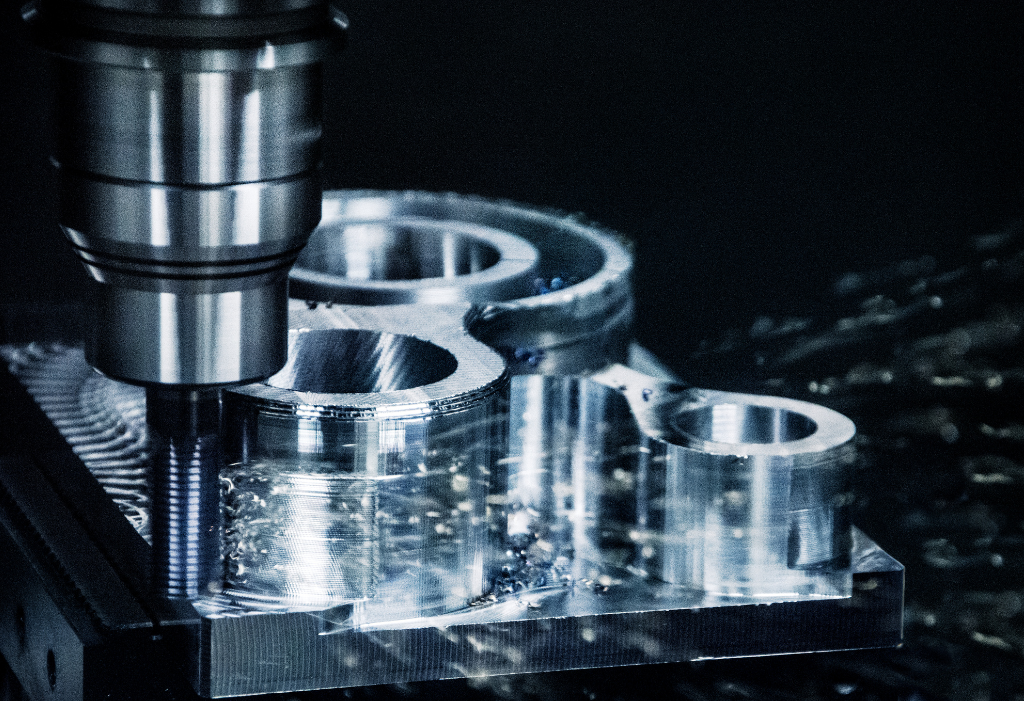

CNC milling machines are like the workhorses of the CNC world. They use rotary cutters to remove material from a workpiece, making them ideal for tasks like cutting, drilling, and shaping various materials, from metals to plastics and wood. Whether you’re crafting intricate prototypes or producing precision parts, CNC milling machines offer incredible versatility.

2. CNC Lathes

If you’re more into turning and shaping cylindrical or conical objects, CNC lathes are your go-to machines. They rotate the workpiece while cutting tools shape it into the desired form. CNC lathes are perfect for creating components like shafts, pins, and custom screws with precision and consistency.

3. CNC Routers

CNC routers are the artists of the CNC world, excelling at intricate carving, engraving, and 2D/3D machining. These machines are a favorite among woodworking enthusiasts, sign makers, and artists looking to transform their digital designs into tangible masterpieces. Whether you’re crafting detailed wooden sculptures or personalized signs, CNC routers make it possible.

4. CNC Plasma Cutters

Need to cut through thick sheets of metal like a hot knife through butter? CNC plasma cutters are your solution. They use a high-velocity jet of ionized gas to cut through metal with precision, making them invaluable in industries like metal fabrication, automotive, and aerospace.

5. CNC 3D Printers

While not technically a traditional CNC machine, CNC 3D printers deserve a mention. They use additive manufacturing to build objects layer by layer, making them ideal for producing intricate prototypes, custom components, and even artistic creations. If you’re passionate about 3D printing, CNC 3D printers are a fantastic addition to your workshop.

Each type of CNC machine has its niche and strengths, so choosing the right one depends on your specific projects and goals. Whether you’re crafting mechanical parts, artistic creations, or custom prototypes, CNC machining offers a world of possibilities waiting for you to explore. So, which CNC machine will you choose for your next project? The choice is yours!

Unlocking the Potential of CNC Machining

In the realm of craftsmanship, CNC machining shines as a game-changer that offers precision, efficiency, and versatility in abundance. CNC machining ensures that every cut, carving, or engraving is executed with flawless precision, replacing uncertainty with pinpoint accuracy. It’s like having a skilled craftsman at your side, guiding each operation to perfection.

Efficiency takes center stage with CNC machining. Gone are the laborious days of manual work, as CNC machines effortlessly handle the heavy lifting. While one project is underway, you can seamlessly shift your focus to sanding or assembling another, all while sipping your coffee.

However, CNC machining isn’t limited to precision and efficiency alone. It’s a versatile tool that expands the horizons of creativity. With CNC technology, you can delve into uncharted territories of intricate inlays and carvings, fostering artistic innovation. +It’s akin to uncovering a hidden level in a video game you never knew existed. The possibilities are boundless, and every project becomes a canvas for your imagination.

Affordability is often a concern for hobbyists, but fear not. The home hobby CNC movement has democratized access to these machines, making them more affordable and attainable than ever. Whether you have a modest budget or are willing to invest more, there are CNC kits to suit every financial plan. The “best” CNC machine is the one that aligns with your budget, skill level, and creative ambitions.

In terms of applications, CNC machining knows no bounds. It finds its place in woodworking, metalworking, jewelry making, and even prototyping. Crafting intricate designs on jewelry pieces or engraving personalized wooden signs becomes a breeze with CNC machining as your trusted ally. It’s a versatile Swiss Army knife, ready to tackle any challenge that crosses its path.

So, if you’re eager to elevate your craftsmanship to new heights, CNC machining is your golden ticket. Precision, efficiency, versatility, and cost-effectiveness are the hallmarks of this technology, catering to both seasoned professionals and budding enthusiasts. Unleash your creativity and let CNC machining handle the rest, for in the world of CNC, there are no limits—only a world of endless possibilities.

Choosing the Right CNC Machine

Assessing Your Needs

Considering Budget and Space

Researching and Comparing Options

Seeking Expert Advice

Getting Started with CNC Machining

Starting with CNC machining can be both thrilling and a bit intimidating.

Understanding G-Code

Testing and Calibration

Starting Simple and Troubleshooting

Begin with straightforward projects to bolster your CNC confidence. Create basic shapes or engrave simple designs, progressively advancing to more complex tasks. Inevitably, you’ll encounter common issues like tool alignment, cutter breakage, or material mishaps. Stay patient and adopt a problem-solving mindset.

Remember, CNC machining mastery takes time. Embrace the learning curve and press onward. With practice and persistence, you’ll become a CNC machining pro. So, dive into this exciting world, learn G-Code, fine-tune your machine, start small, and tackle challenges head-on. Prepare for a journey that will test and reward your creativity, taking your craftsmanship to new heights.

Expanding Your Skills and Knowledge

In the realm of CNC machining, continuous skill and knowledge development are essential for personal and professional growth. It presents countless opportunities for individuals to expand their expertise and capabilities. Let’s delve into some crucial insights that can help your proficiency from a beginner level to a pro-level rapidly:

- Joining Online Communities: Online forums and groups are treasure troves of knowledge and experience. Whether you need advice or want to share your insights, these communities have your back. Engage in discussions, attend webinars, and learn from like-minded enthusiasts.

- Attending Workshops and Classes: For a hands-on approach, consider workshops and classes tailored to CNC machining. Industry experts can help you gain practical experience and connect with fellow enthusiasts in a classroom setting.

- Experimenting with Advanced Techniques: Push your boundaries by trying complex designs and multi-axis machining. Exploring new techniques expands your skill set and unlocks creative possibilities.

- Continuously Learning and Improving: CNC machining is always evolving. Stay updated with industry trends, read blogs, watch tutorials, and attend seminars. Continuous learning ensures your skills remain top-notch.

Embrace this journey of growth and discovery in CNC machining. By following these steps, you’ll become a CNC master in no time.

Conclusion

This beginner’s guide has taken you through the wonderful world of CNC machining. From understanding the basics to exploring advanced techniques, you’re now equipped with the knowledge to embark on your own CNC machining adventure. Whether you’re a hobbyist looking to bring your creative ideas to life or a professional aiming to take your business to new heights, CNC machining is an exciting and rewarding skill to master.

But why stop at just mastering the knowledge when you can bring your CNC projects to life with precision and expertise? Consider Ethereal Machine’s CNC Machining Services. Our team of skilled professionals and state-of-the-art equipment can help turn your ideas into reality. Whether it’s a one-time project or ongoing production needs, we’re here to provide you with top-quality CNC machining solutions. Don’t miss out on the opportunity to take your CNC projects to the next level.

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 781