Maximizing Precision in CNC Machining with Integrated CAD/CAPP/CAM Technologies

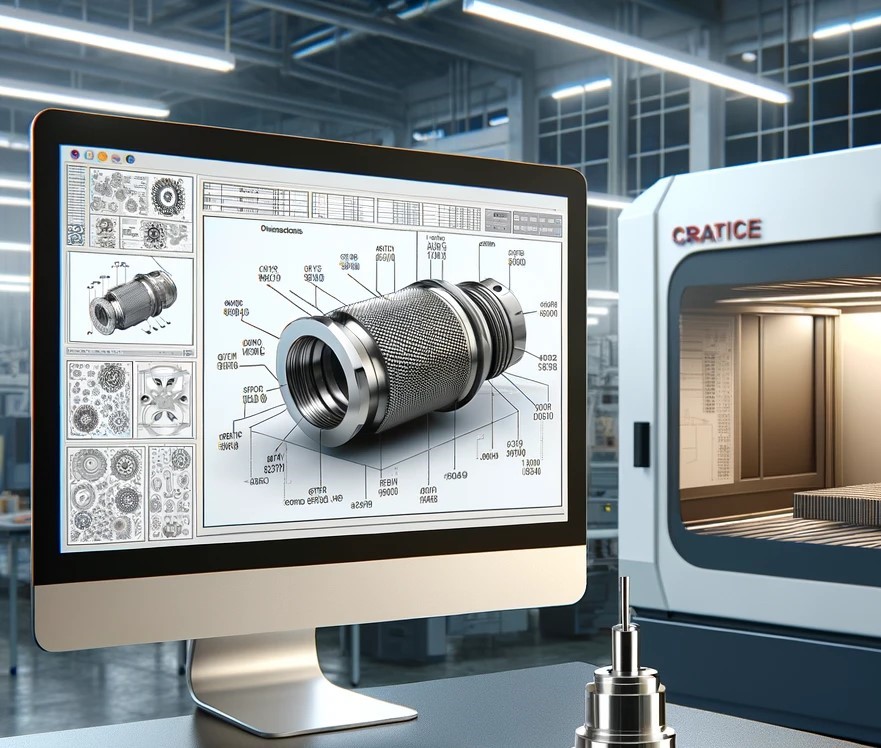

This integration is not merely an incremental improvement but a transformative shift in the way we conceptualize, design, and execute the manufacturing of complex parts. This synergy enables the fabrication of components with complexities and tolerances once deemed unattainable, particularly in high-precision industries such as aerospace, automotive, and medical devices.

From Concept to Reality: The Role of CAD

CAD is the foundation for modern design and engineering. CAD systems enable designers and engineers to create highly detailed, three-dimensional models of parts and assemblies. These models are not merely visual representations; they embody the precise dimensions, tolerances, and materials required for the intended application. The power of CAD lies in its ability to simulate and test designs under various conditions before a single piece of material is cut, ensuring that potential issues are identified and addressed early in the design process.

CAM: Bridging Design and Manufacturing

The sophistication of CAM systems allows for the simulation of machining processes, providing engineers with a visual preview of how the CNC machine will execute the operations. This simulation is crucial for identifying potential problems, such as tool collisions or areas where the tool path may not produce the desired finish before the machining process begins. By addressing these issues in the CAM stage, manufacturers can avoid costly errors and material waste.

The Role of CAPP in Enhancing CNC Machining

Optimizing Machining Strategies: The Core of CAPP

The essence of CAPP lies in its ability to optimize machining strategies. This involves a meticulous selection process for cutting tools, sequencing operations in the most logical and efficient manner, and precisely setting machining parameters such as speed, feed rate, and depth of cut. These decisions are critical, as they directly impact the manufacturability of parts, affecting everything from production time to material wastage and overall part quality.

CAPP systems leverage advanced algorithms and a wealth of manufacturing data to determine the best course of action for each unique manufacturing scenario. By analyzing the part design, material specifications, and desired tolerances, CAPP can identify the most efficient and effective manufacturing strategies, tailored to the specific requirements of the project.

Facilitating Precision and Efficiency

The integration of CAPP in CNC machining highlights its pivotal role in facilitating precision and efficiency. By developing a detailed and optimized process plan, CAPP ensures that the manufacturing operations are not only feasible but are executed in the most efficient manner possible. This optimization minimizes the risk of errors and inconsistencies, which is particularly crucial in industries where precision is paramount, such as aerospace, medical devices, and automotive manufacturing.

Moreover, CAPP enables a more dynamic and responsive manufacturing environment. As design changes occur or new efficiencies are identified, CAPP can quickly adjust the process plans to accommodate these changes, ensuring that the manufacturing process remains as efficient and effective as possible. This adaptability is essential in today’s fast-paced market, where the ability to respond quickly to design changes or market demands can provide a significant competitive advantage.

Enhancing Collaboration and Integration

CAPP also plays a vital role in enhancing collaboration between the design and manufacturing teams. By providing a clear and detailed process plan, CAPP ensures that the manufacturing considerations are taken into account early in the design phase. This early integration helps to identify potential manufacturability issues, allowing for design modifications before the production phase, thereby reducing the risk of costly rework or delays.

The collaboration fostered by CAPP extends beyond the internal teams. By generating detailed process plans and documentation, CAPP facilitates communication with external partners, such as suppliers and subcontractors, ensuring that they have a clear understanding of the manufacturing requirements. This collaborative approach ensures that all parties are aligned, further enhancing the efficiency and quality of the manufacturing process.

Enhancing Precision and Efficiency through CNC, CAD/CAPP, and CAM Synergy

Precision Engineering: The Heart of CNC Machining

Precision is the cornerstone of CNC machining, where even the minutest inaccuracies can lead to significant repercussions for the functionality and reliability of the manufactured parts. The integration of CAD/CAPP/CAM technologies ensures that every aspect of a component is meticulously planned, designed, and executed with the highest levels of accuracy.

- CAD’s Role in Precision Design: CAD software allows for the creation of complex 3D models that accurately represent the final product, including all necessary specifications and tolerances. These models serve as the blueprint for the manufacturing process, ensuring that the design is both feasible and optimized for machining.

- CAPP’s Contribution to Strategic Planning: CAPP systems take these CAD models and develop a comprehensive manufacturing strategy that includes tool selection, operation sequencing, and parameter setting. This strategic planning ensures that the machining process is not only efficient but also executed with precision, minimizing the risk of errors and material waste.

- CAM’s Execution of Precise Machining: CAM software translates the optimized process plans into G-code, directing the CNC machines to execute the designs with exacting precision. This ensures that the physical part matches the CAD model to the highest degree of accuracy, adhering to the specified tolerances and surface finishes.

Efficiency Gains from Integrated Technologies

The efficiency improvements from this integrated approach extend beyond reducing the machining time. They encompass the entire manufacturing workflow, from design to final production, optimizing every step to save time, reduce costs, and minimize waste.

- Streamlined Workflow: The seamless integration of CAD, CAPP, and CAM technologies streamlines the transition from design to manufacturing. This cohesive workflow reduces the time spent on manual data entry, process planning, and programming, allowing for quicker turnaround times.

- Material and Tool Optimization: By meticulously planning the machining process, CAPP helps in optimizing material usage and tool life. This not only reduces material costs but also decreases downtime due to tool changes, enhancing overall production efficiency.

- Adaptability and Flexibility: The integrated system offers greater flexibility in responding to design changes or customizations. Since the design, planning, and machining processes are closely linked, modifications can be quickly implemented, allowing manufacturers to adapt to customer requirements or design improvements with minimal disruption.

Pioneering Advanced CNC Solutions Through Integration

Customization at the Core

One of the most significant advantages of integrating CAD, CAPP, and CAM with CNC machinery is the unparalleled level of customization it offers. Traditional manufacturing methods are often limited by the constraints of manual process planning and the inherent limitations of standalone machining operations. However, the dynamic interaction between CAD design, CAPP process optimization, and CAM programming allows for an almost infinite level of detail and complexity in manufactured parts.

- CAD for Design Innovation: CAD software is continuously evolving, incorporating more sophisticated algorithms and modeling capabilities. This evolution enables designers to explore complex geometries and innovative designs that were previously unachievable, pushing the envelope of creativity and functionality in component design.

- CAPP for Customized Process Planning: The sophistication of CAPP systems lies in their ability to take these innovative designs and develop highly customized and efficient machining strategies. By considering factors such as material properties, machining dynamics, and tool wear, CAPP creates a tailored process plan that optimizes every aspect of the manufacturing process.

- CAM for Precision Execution: CAM systems translate these optimized process plans into precise machining instructions. With advanced simulation capabilities, CAM software ensures that the CNC machinery can execute complex designs with high precision, adapting to the unique requirements of each project.

Advanced Manufacturing for Complex Components

The integration of these technologies has profound implications for the manufacturing of complex components, particularly those within the 400mm size range. For instance, the production of intricate engineering parts like impellers or connectors, which require not only precision but also a nuanced understanding of material properties and machining dynamics, benefits immensely from this integrated approach.

- Tailored Tool Paths: By customizing tool paths based on the component’s design and the selected material, manufacturers can significantly improve the quality and performance of the finished product. This customization also extends to adjusting machining parameters in real-time, ensuring optimal tool engagement and material removal rates.

- Proprietary Machining Strategies: The development of proprietary machining strategies is another area where this integration shines. By leveraging the combined capabilities of CAD, CAPP, and CAM, manufacturers can innovate unique approaches to machining that enhance efficiency, reduce cycle times, and improve the overall quality of the machined parts.

Advanced Manufacturing for Complex Components

Through active engagement in reshaping the capabilities of precision manufacturing, the integration of CNC with CAD/CAPP/CAM technologies is setting new industry standards. This bespoke approach to manufacturing ensures that each component not only meets but exceeds the requirements of high-precision applications.

- Innovation in Action: An excellent example of this innovation in action is the fabrication of aerospace components, where the margin for error is virtually zero. The integrated approach allows for the production of parts that meet stringent aerospace standards, demonstrating the superior precision and reliability that this technology offers.

Boosting Competitiveness with CNC, CAD/CAPP, and CAM Integration

Superior Design and Production Capabilities

- Complex Parts with Extreme Precision: The seamless transition from digital design in CAD to physical production through CAM, guided by the strategic process planning of CAPP, enables manufacturers to produce parts with complexities and tolerances that were previously unfeasible. This capability is invaluable in industries such as aerospace, automotive, and medical devices, where the precision and reliability of components can directly influence the safety and efficacy of the final products.

- Rapid Prototyping and Iteration: The integration facilitates rapid prototyping, allowing manufacturers to quickly transition from design to prototype. This speed is crucial for iterative design processes, where multiple prototypes may be required to refine product designs. The ability to rapidly produce prototypes not only accelerates the development cycle but also enables a more agile response to market demands and technological advancements.

Efficiency and Cost-Effectiveness

- Streamlined Manufacturing Workflow: By eliminating the need for manual intervention between design and production stages, the integrated approach significantly reduces production lead times. This efficiency is not just a matter of faster production; it’s about the smart allocation of resources, minimizing waste, and optimizing the use of machinery and materials.

- Customization and Scalability: The flexibility offered by the integrated system allows for the efficient production of both custom and standard parts. This adaptability is a considerable advantage for manufacturers looking to serve a broad market spectrum, from bespoke solutions to mass-produced components, without compromising on precision or efficiency.

Conclusion

<span data-metadata=""><span data-metadata=""><span data-buffer="">MAAS

Machining As A Service

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 810