Navigating CNC Machining Innovation: 2024 & Beyond

Bridging Innovation and Tradition

Smart Factories

At the core of smart factories lies the integration of Artificial Intelligence (AI) and the Internet of Things (IoT). AI enables machines to process vast amounts of data, identify patterns, and make informed decisions, enhancing the precision and flexibility of CNC machining operations. Meanwhile, IoT devices facilitate seamless communication between machines, tools, and systems, ensuring that every component of the manufacturing process is in perfect harmony.

- Production Ecosystems with IoT Integration: The IoT’s role in smart factories is to create a cohesive production ecosystem. By equipping CNC machines, tools, and production lines with IoT sensors, manufacturers gain real-time insights into every aspect of the manufacturing process. This visibility enables the optimization of workflows, the reduction of waste, and the ability to respond swiftly to changes in production demands or specifications. Moreover, IoT integration supports the development of digital twins—virtual replicas of physical assets—which can be used to simulate and optimize manufacturing processes before they are implemented on the factory floor.

- AI-Driven Predictive Maintenance: One of the most significant advantages of smart factories is the implementation of AI-driven predictive maintenance. Traditional maintenance schedules rely on set intervals, often leading to unnecessary downtime or, worse, unexpected machine failures. Predictive maintenance, on the other hand, uses AI algorithms to monitor the condition of machinery in real time, predicting failures before they occur. This not only minimizes downtime but also extends the lifespan of CNC machines, significantly reducing long-term operational costs.

The ongoing advancements in AI and IoT technologies promise even greater levels of automation, efficiency, and innovation. However, to fully realize the potential of smart factories, manufacturers must invest in continuous learning, upskill their workforce, and embrace the cultural shift toward digital transformation.

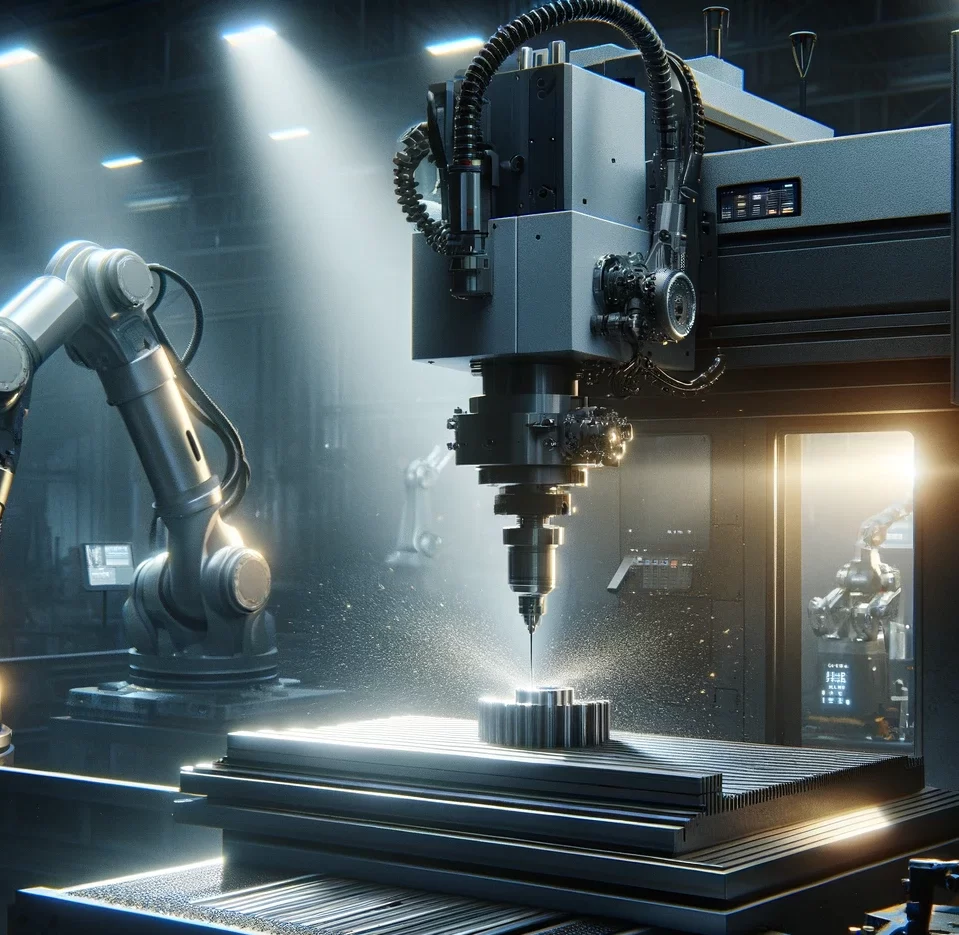

The Dawn of Hybrid Manufacturing

Hybrid manufacturing stands as a testament to the power of technological convergence. By integrating CNC machining’s subtractive processes with the additive processes of 3D printing, manufacturers can produce parts that were previously unimaginable. This synergy allows for the creation of components with complex geometries, internal structures, and materials that traditional methods could not achieve alone.

- Enhancing Flexibility and Reducing Waste: One of the paramount advantages of hybrid manufacturing is its potential to significantly reduce material waste. Traditional CNC machining often involves removing significant portions of the material to achieve the desired shape, which can be inefficient and costly, especially with expensive materials like titanium or aerospace-grade alloys. Additive manufacturing, by contrast, builds parts layer by layer, using material only where it’s needed. Combining these approaches means manufacturers can first additively build a near-net shape and then finish it with the precision of CNC machining, optimizing material usage and reducing waste.

- The Role of Software and Simulation: The rise of hybrid manufacturing has been facilitated by advancements in software and simulation technologies. Modern CAD/CAM systems now offer integrated workflows that seamlessly transition between additive and subtractive processes, allowing designers and engineers to optimize designs for hybrid manufacturing from the outset. Furthermore, simulation software enables the prediction of potential issues in the additive process, such as distortions or support structure complications, ensuring that the subsequent CNC machining process is as efficient as possible.

Looking forward, the potential of hybrid manufacturing is boundless. As research and development continue to enhance the capabilities of both additive and subtractive technologies, the range of applications for hybrid manufacturing will expand. From medical implants tailored to individual patients to lightweight, high-strength components for electric vehicles, hybrid manufacturing is set to play a pivotal role in the next generation of manufacturing challenges.

Sustainability and Efficiency

Green Manufacturing

The urgent need for environmental stewardship is pushing the CNC machining industry towards greener pastures. In 2024, sustainable practices will transition from optional to essential, manifesting through:

- Renewable Energy Adoption: Forward-thinking CNC machining firms are transitioning to renewable energy sources to power their operations. This shift not only reduces the carbon footprint of manufacturing activities but also aligns with global efforts to combat climate change. For instance, solar and wind energy are increasingly used to power CNC machines, offering a cleaner, more sustainable alternative to fossil fuels.

- Eco-Friendly Materials and Processes: There’s a growing emphasis on using recyclable materials and eco-friendly lubricants and coolants in CNC machining. These practices help reduce harmful emissions and waste, contributing to a healthier environment. Additionally, advancements in material science are enabling the use of bio-based polymers and composites, which offer a sustainable alternative to traditional plastics and metals.

This shift towards sustainability reflects a growing recognition of the industry’s responsibility towards the planet and future generations.

Refining Manufacturing with Lean Principles

Lean manufacturing principles are being embraced within the CNC machining sector to enhance efficiency and reduce waste. This approach focuses on streamlining operations, eliminating non-value-added activities, and optimizing resource use.

- Waste Reduction and Process Optimization: By identifying and eliminating inefficiencies, CNC machining operations can significantly reduce waste—whether it’s material scraps, excessive energy use, or time. Techniques such as value stream mapping and continuous improvement (Kaizen) are instrumental in realizing these efficiencies.

- Agility and Flexibility in Production: Lean manufacturing also promotes agility and flexibility, allowing manufacturers to quickly adapt to changing market demands or shifts in production requirements. This responsiveness is crucial in today’s fast-paced market, where customer expectations and technological advancements evolve rapidly.

As the CNC machining industry continues to evolve, sustainability and efficiency will remain at the forefront of innovation. The integration of green manufacturing practices and lean principles is not just a trend but a fundamental shift in how businesses operate. Companies that embrace these imperatives are setting new standards for excellence, paving the way for a future where CNC machining is synonymous with environmental stewardship and operational efficiency.

Technological Synergy for Competitive Edge

Collaborative Robots in CNC Machining

Cobots are designed to work alongside human operators, combining the strengths of human intuition and robotic efficiency. Unlike traditional industrial robots, which require safety barriers, cobots are equipped with advanced sensors and AI algorithms that allow them to safely interact with humans in a shared workspace.

- Enhancing Safety and Efficiency: By taking on repetitive, physically demanding, or hazardous tasks, cobots reduce the risk of workplace injuries. This enhances safety and allows human workers to focus on more complex, value-added activities. For example, cobots can be used for loading and unloading CNC machines, a task that is monotonous yet requires precision.

- Scalability and Flexibility: Cobots offer CNC machining operations the flexibility to scale production up or down without significant downtime or reconfiguration. Their intuitive programming and ease of integration make them ideal for small-batch production and custom manufacturing, areas where CNC machining excels.

Digital Tools Elevating Human Capabilities

The rise of digital tools, from sophisticated CAD/CAM software to IoT devices and AI-driven analytics, is providing human operators with unprecedented insights and control over the manufacturing process.

- Predictive Analytics and Maintenance: AI and machine learning algorithms can analyze data from CNC machines in real-time, predicting maintenance needs and optimizing machining parameters for efficiency and quality. This predictive approach ensures machines operate at peak performance, with minimal downtime, directly impacting productivity and the bottom line.

- Augmented Reality (AR) for Training and Operations: AR technology is becoming an invaluable tool in CNC machining, offering immersive training experiences that accelerate learning curves for new operators. Additionally, AR can overlay digital information onto physical machinery, guiding operators through complex setups or troubleshooting procedures, thereby enhancing precision and reducing errors.

Fortifying the Digital Front: Cybersecurity

As the CNC machining industry embraces digital transformation, its interconnected systems become increasingly vulnerable to cyber threats. Cybersecurity has thus emerged as a pivotal concern, with the integrity of manufacturing operations, the protection of intellectual property, and the trust of customers at stake. The journey toward securing the digital landscape of CNC machining involves advanced technological solutions, awareness, and vigilance at every level of operation.

Rising Cyber Threats in Manufacturing

Advanced Solutions for Cybersecurity

To combat these threats, CNC machining firms are increasingly investing in advanced cybersecurity measures:

- Encryption and Firewall Technologies: Encrypting data in transit and at rest ensures that sensitive information, such as design files and operational parameters, is secure from unauthorized access. Firewalls serve as the first line of defense, preventing unauthorized access to networked machines and systems.

- Regular Cybersecurity Audits and Employee Training: Regular audits of cybersecurity practices help identify potential vulnerabilities, ensuring that security measures are up-to-date and effective. Equally important is training employees on cybersecurity best practices, making them aware of potential threats and actions they can take to prevent breaches.

A Culture of Cyber Vigilance

Creating a culture of cybersecurity within the CNC machining industry goes beyond implementing technology. It involves fostering an environment where every employee understands the importance of cybersecurity and is equipped with the knowledge to act proactively against threats. This culture of vigilance is crucial in an era where cyber threats are constantly evolving.

As the CNC machining industry continues to evolve, the importance of cybersecurity will only increase. The future of manufacturing is undeniably digital, making the protection of digital assets a top priority. Companies that prioritize cybersecurity will not only protect themselves from potential threats but will also position themselves as leaders in the digital manufacturing landscape, ready to embrace new opportunities with confidence.

Envisioning the Future of CNC Machining

The journey into 2024 and beyond offers the CNC machining industry a vista of opportunities enriched by innovation, sustainability, and technological advancement. Adapting to these trends requires investment in new technologies and a commitment to continuous learning and improvement.

Embracing these pivotal changes can elevate CNC machining from a conventional production method to a cornerstone of futuristic manufacturing, marked by efficiency, precision, and resilience. As we navigate this transition, the success of the CNC machining industry will lie in its ability to anticipate future challenges and harness emerging opportunities, steering towards a future forged in the fires of innovation and shaped by the hands of skilled professionals.

The road ahead is complex, but with these trends as our guideposts, the CNC machining industry is poised to tackle the challenges head-on, driving growth, innovation, and excellence. Let’s delve further into how these developments unfold and their broader implications for the industry.

Mastering the Material Revolution

As we push the boundaries of what’s possible within CNC machining, the exploration and incorporation of new materials will play a pivotal role. Innovative materials, including advanced composites, superalloys, and bio-based polymers, offer unique properties that can revolutionize product design and functionality. Embracing these materials will require:

- They advanced tooling and machining strategies to handle their unique characteristics efficiently.

- Strong partnerships with material scientists and engineers to stay ahead of the curve in material technology.

This focus on material innovation not only enhances product offerings but also aligns with sustainability goals by exploring recyclable and environmentally friendly options.

Expanding the Horizons of Machine Intelligence

The infusion of artificial intelligence (AI) into CNC machining goes beyond operational efficiency. AI’s potential to transform the industry encompasses:

- Predictive analytics for machine maintenance, significantly reducing unexpected downtimes.

- Enhanced quality control through real-time adjustments during the machining process, ensuring unparalleled precision and reducing waste.

These AI-driven improvements signify a leap towards fully autonomous production lines, where decision-making is data-driven, optimizing every aspect of the manufacturing process.

Building Resilient Supply Chains

Recent global events have underscored the importance of resilience and adaptability in manufacturing supply chains. For the CNC machining industry, this means diversifying supplier networks and leveraging digital tools to enhance visibility and responsiveness.

Blockchain technology, for instance, can provide a secure and transparent way to trace materials and components, ensuring their authenticity and quality.

A resilient supply chain is crucial for maintaining production schedules and meeting customer demands, making it an essential component of future-proofing CNC machining operations.

Elevating Customer Experience through Technology

In an era where customer expectations are higher than ever, leveraging technology to enhance customer experience becomes a competitive advantage. CNC machining companies can achieve this by:

- Utilizing AR (Augmented Reality) and VR (Virtual Reality) for immersive product demonstrations and prototyping.

- Implementing advanced e-commerce platforms and customer portals for streamlined ordering and tracking.

These technological touchpoints create a more engaging and informative customer journey, building loyalty and trust in the CNC machining brand.

Fostering a Culture of Continuous Learning

As the CNC machining industry rapidly evolves, the workforce must keep pace. Emphasizing continuous learning and development ensures that employees:

- Are skilled in the latest technologies and methodologies, enhancing productivity and innovation.

- Feel valued and invested in, reducing turnover and fostering a culture of excellence.

Investing in human capital is just as important as investing in technology, as a skilled and motivated workforce is essential for navigating the future of manufacturing.

Conclusion

The future of the CNC machining industry is bright and filled with the promise of technological innovations, sustainable practices, and new growth opportunities. However, unlocking this potential requires deliberate action today—investing in technology, nurturing talent, and fostering innovation.

As we look towards 2024 and beyond, it’s clear that the CNC machining industry is not just responding to change but is actively shaping the future of manufacturing. By embracing these trends, CNC machining firms can redefine what’s possible, driving forward with resilience, agility, and a steadfast commitment to excellence.

In this dynamic landscape, the path forward may be complex, but it is also incredibly exciting. For CNC machining professionals, the journey ahead is not just about tackling challenges but about seizing opportunities to innovate, improve, and inspire. The future is not just something to prepare for—it’s something to create, and the CNC machining industry is poised to lead the way.

<span data-metadata=""><span data-metadata=""><span data-buffer="">MAAS

Machining As A Service

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 1053