Perfecting Fits in Manufacturing

Fits are an essential component in the engineering and manufacturing world, offering a secure and durable method of joining two parts without the need for additional fasteners like screws or adhesives. Imagine fitting together two puzzle pieces—fits ensure that these pieces connect with just the right amount of force, staying firmly in place. Whether it’s in the construction of aerospace components, medical devices, or everyday electronics, understanding fits can help engineers design more reliable and efficient products.

The principle behind a Fit is simple: a slightly oversized part is pressed into a slightly undersized hole, creating a tight interference fit. This fit relies on friction between the two surfaces to hold them together securely. But while the concept is straightforward, the application requires careful consideration of materials, tolerances, and assembly techniques.

Understanding Fits

Fits might seem simple, but they are crucial in ensuring that components in various industries, from aerospace to consumer electronics, stay firmly together without the need for screws or adhesives. Essentially, fits work by pressing a slightly larger part into a smaller hole, creating a secure bond through friction.

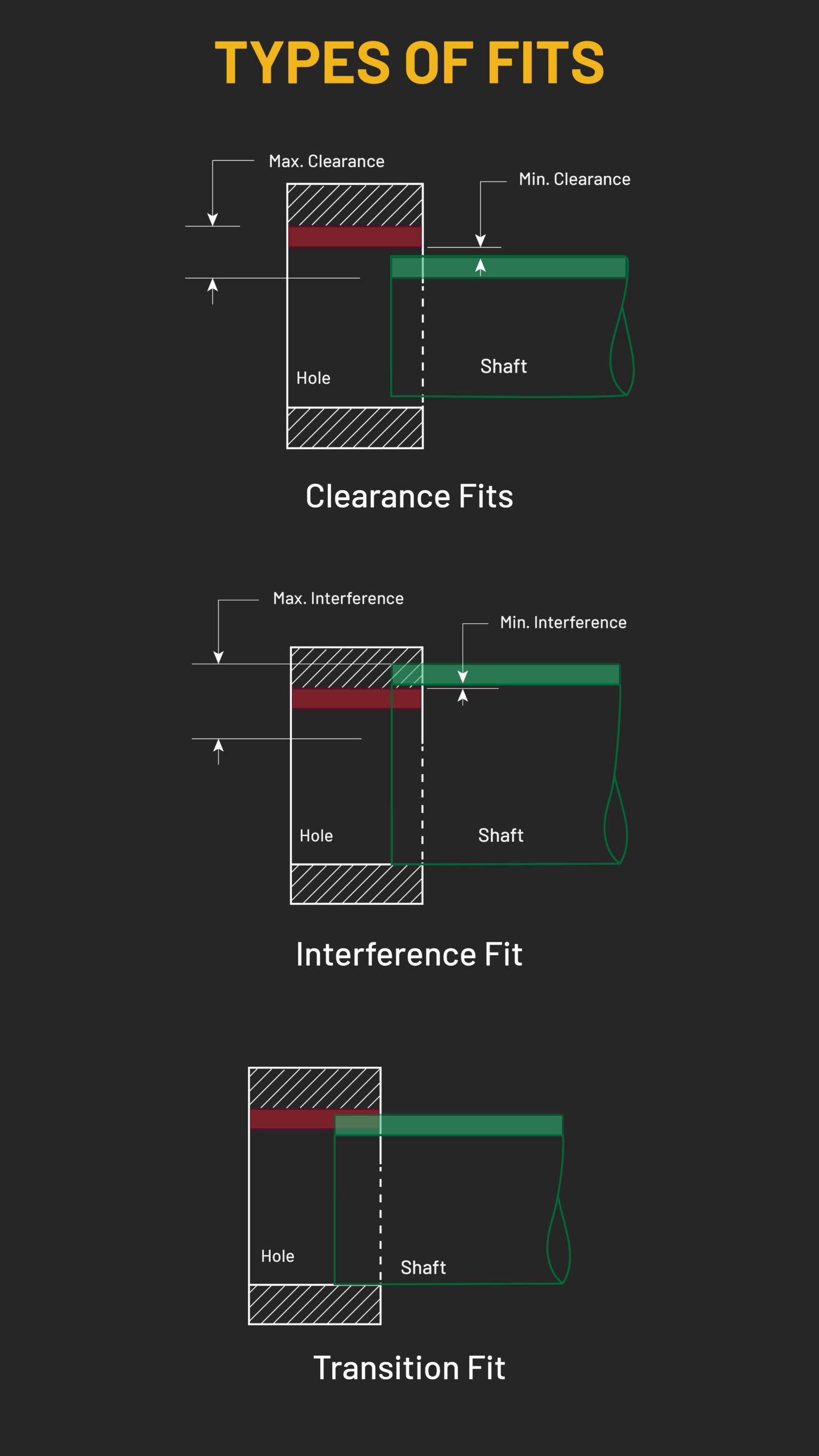

There are several types of fits, each suited to different applications. Understanding these types can help in choosing the right method for a specific project:

Clearance Fits

Clearance fits are used when components need to move freely relative to each other. The hole is slightly larger than the inserted part, allowing for movement without compromising the assembly. Subtypes include:

- Loose Running Fit: Allows for maximum movement, ideal for parts that need to slide easily, such as in machinery or piping.

- Free Running Fit: Provides a balance between movement and stability, often used in rotating components where smooth operation is crucial.

- Sliding Fit: Offers controlled movement with minimal clearance, ensuring that the parts move smoothly but with minimal play, which is important in precision machinery.

Interference Fits

Interference fits are used when a secure, permanent connection is necessary. The inserted part is slightly larger than the hole, creating a tight fit. Here are some common subtypes:

- Force Fit: Requires significant force for assembly and is typically irreversible. Ideal for components that must remain fixed indefinitely, like wheels on axles.

- Shrink Fit: This involves heating the outer component so it expands, allowing the inner part to be inserted. Upon cooling, the outer component contracts, securing the fit. It’s commonly used in situations where a strong bond is needed without applying excessive force during assembly.

- Press Fit: Often used in mechanical assemblies, this fit involves pressing the parts together using a press machine. It provides a reliable, secure bond while still allowing for some level of disassembly if needed.

Transition Fits

Transition fits are designed to balance security and ease of assembly. They provide a moderate level of interference or clearance, making them suitable for parts that might need to be disassembled or adjusted. Key subtypes include:

- Medium Fit: Offers slight interference, making it easier to assemble than a force fit but still secure enough to prevent movement. It’s often used in applications like gear assemblies where components must remain aligned.

- Tight Fit: Provides more security than a medium fit but still allows for disassembly if needed. This fit is ideal for applications where parts need to be precisely aligned but might require occasional maintenance.

Each type of fit serves a specific function, depending on the desired balance between ease of assembly and the need for a secure, durable connection. Understanding these types and their subtypes helps in making informed decisions during the design and assembly process.

The Science Behind Fits

Fits aren’t just about pushing one part into another; there’s a lot of science behind ensuring that fit is perfect. The material properties, such as hardness and thermal expansion, play a significant role in the success of a fit. For example, metals expand and contract with temperature changes, which can affect the fit over time.

Tolerance is another critical factor. The tightness of the fit, measured in microns, determines whether the assembly will be too loose, too tight, or just right. Getting this balance is crucial to avoiding issues like material stress or failure.

Thermal expansion also requires careful consideration. As parts heat up during operation, they expand, potentially leading to loosening or cracking. Engineers must account for this when designing press fits to ensure reliability under all conditions.

When to Use Fits

Fits are particularly useful in applications where a permanent, high-strength bond is required. For example, in aerospace and automotive industries, fits are often used to ensure that components remain securely in place even under extreme conditions.

However, knowing when to use a fit versus another assembly method is crucial. Fits are ideal for situations where disassembly is not needed, as they are generally designed to be permanent. They also work well when the assembly process needs to be streamlined, as they eliminate the need for additional fasteners.

While fits offer many advantages, there are challenges, such as the risk of deformation or difficulty in disassembly. Understanding these challenges and carefully planning the assembly process can help ensure that press fits are used effectively.

Common Challenges and Solutions

While fits offer many advantages, they do come with their own set of challenges. One common issue is the potential for deformation, especially if the parts are pressed together with excessive force. This can lead to stress within the material, potentially causing cracks or even complete failure over time.

Another challenge is dealing with thermal expansion, particularly in environments where temperatures fluctuate. As materials expand and contract, the fit can loosen or tighten, leading to potential issues. To address these challenges, it’s essential to carefully control the assembly process, ensuring that the fit is neither too tight nor too loose.

One effective solution is to use precision alignment tools during the assembly process. This helps ensure that the parts are aligned correctly, reducing the risk of deformation. Additionally, it’s crucial to account for thermal expansion during the design phase, selecting materials that will behave predictably under varying temperatures.

Best Practices for Achieving Perfect Fits

Achieving a perfect press fit requires careful planning and execution. One of the most critical aspects is the design phase, where material properties and tolerances must be carefully calculated to ensure a secure fit. During this phase, considering factors like thermal expansion and the operating environment is crucial to prevent issues down the line.

Quality control is also vital. Using advanced inspection techniques, such as 3D scanning or X-ray imaging, can help ensure that the parts meet the required specifications. These techniques allow for precise measurements and the early identification of potential issues, ensuring that the press fit will perform reliably in its intended application.

In addition to precision in design and inspection, proper assembly techniques are essential. This includes using the right tools and ensuring that the parts are aligned correctly before pressing them together. By following these best practices, you can achieve a press fit that is both secure and durable, minimizing the risk of failure.

Conclusion

Understanding the intricacies of fits is essential for engineers and manufacturers aiming to create reliable and efficient products across various industries. From selecting appropriate materials and calculating precise tolerances to implementing meticulous assembly and quality control processes, every step plays a vital role in achieving a successful press fit.

By carefully considering factors such as thermal expansion and the specific demands of the operating environment, designers can prevent common issues like deformation and failure. Employing best practices and utilizing advanced technologies ensures that press fit assemblies maintain their integrity and performance over time.

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 579