Role of CNC in the Evolution of the Semiconductor Industry

However, it’s crucial to navigate this discussion with a clear focus. While the allure of nanotechnology and its groundbreaking applications in the semiconductor industry are widely recognized, our journey today takes a different path. We explore the domain where CNC machining excels in its ability to achieve precision at the micron level. Although this scale is not as small as the Nano-level, it is vital for manufacturing excellence in the semiconductor industry.

At Ethereal Machines, we understand that the finesse of micron-level precision is not just a requirement but a benchmark for quality and efficiency in semiconductor manufacturing. In this extensive exploration, we aim to shed light on how CNC technology, a cornerstone of our expertise, plays a pivotal role in shaping the semiconductor industry. From the intricate details of small dimensions to the robust capabilities of our CNC machining services, we will uncover how precision engineering is not just about meeting standards, but setting them.

Join us as we embark on this insightful journey, unraveling the critical role of CNC in the evolution of the semiconductor industry, and illustrating how Ethereal Machines stand these technological advancements.

The Evolution of the Semiconductor Industry

In the 1970s, the semiconductor industry underwent a monumental shift with the introduction of the microprocessor. Companies like Intel spearheaded this revolution, producing chips that became the central processing units of computers, ushering in the age of personal computing. This period was also defined by Moore’s Law, an observation made by Intel co-founder Gordon Moore, which predicted the exponential growth of computing power by noting that the number of transistors on a chip would double approximately every two years. This law not only described the incredible pace of technological advancement but also served as a target for the industry, driving continual innovations in photolithography, material science, and chip design.

As the industry entered the 21st century, it faced new challenges and opportunities. The rise of artificial intelligence (AI) and the Internet of Things (IoT) created a demand for specialized chips capable of handling extensive data processing and connectivity. However, as the industry approached the physical limits of Moore’s Law, companies began exploring alternative architectures and materials, such as graphene and silicon carbide, to overcome the challenges of miniaturization. Additionally, the increasing importance of sustainability and green computing has led to a focus on more sustainable manufacturing practices and the development of energy-efficient semiconductors.

Today, the semiconductor industry stands at a crossroads, shaped by its rich history of innovation and facing a future filled with both challenges and immense potential. From powering the earliest computers to enabling the latest AI technologies, semiconductors have been fundamental to technological progress, and their evolution will continue to be pivotal in shaping the digital landscape of the future.

The Role of CNC Machining in Semiconductor Manufacturing

Understanding CNC Technology in Precision Manufacturing

Meeting the Demand for High Precision at Small Dimensions

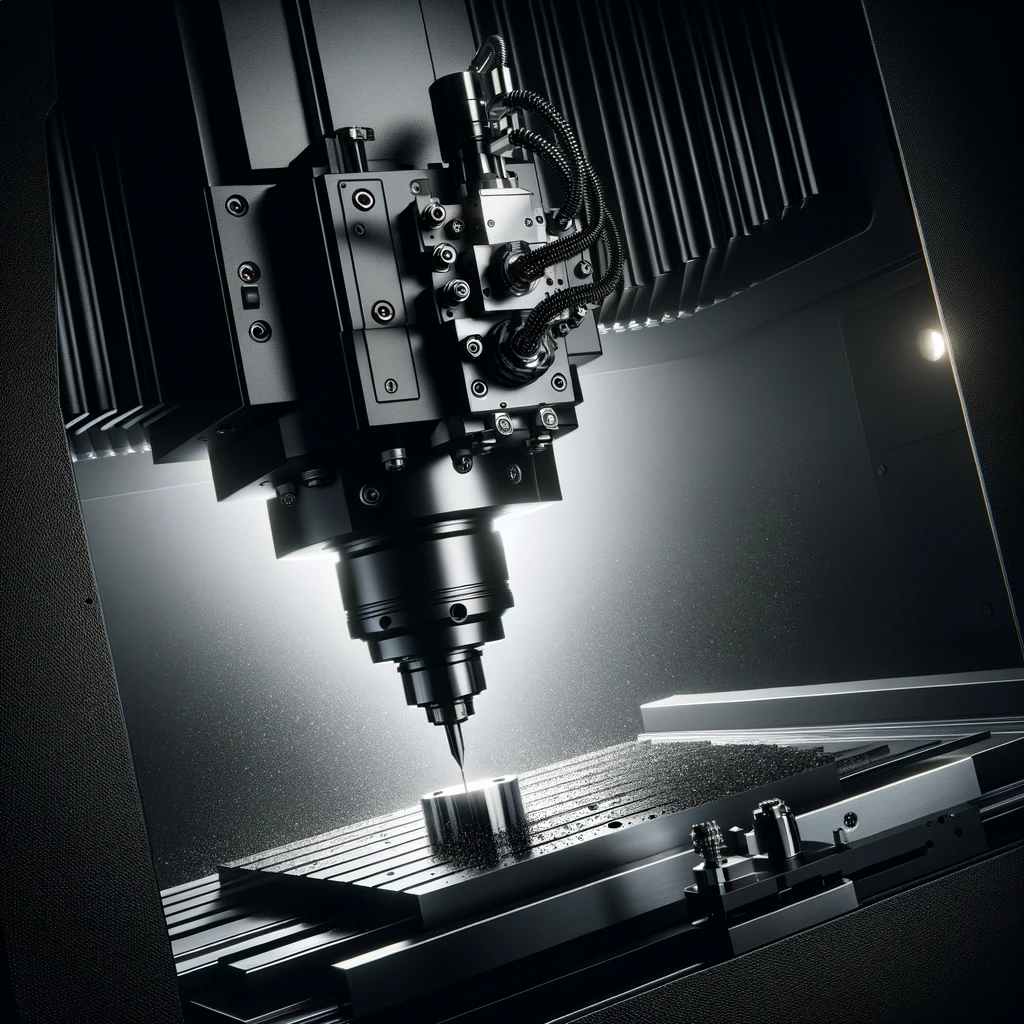

In the semiconductor industry, where the margin for error is incredibly slim, CNC machining stands out for its ability to consistently produce parts with micron-level precision. The importance of this level of accuracy cannot be overstated. Even the slightest deviation can lead to significant performance issues or complete failure of semiconductor devices. CNC machines, with their advanced controls and precision tooling, can maintain tolerances within a few microns, ensuring that each component meets the stringent standards required.

CNC Machining in Action

To illustrate the role of CNC machining in semiconductor manufacturing, let’s consider two real-world applications.

- Heat Sinks: Heat sinks are crucial for dissipating heat from electronic components. These heat sinks often require complex geometries and exact dimensions to function effectively. CNC machining allows for the creation of these intricate designs with the necessary precision.

- Semiconductor Enclosures: The production of semiconductor enclosures is another area where CNC machines shine. They are used to ensure that the housing is perfectly sized and shaped to protect delicate electronic components.

CNC Solutions for the Semiconductor Industry

At Ethereal Machines, we have embraced the challenge of providing CNC solutions tailored specifically for the semiconductor industry. Our state-of-the-art CNC machines are designed to handle the demands of micron-level precision manufacturing. With advanced software and cutting-edge tooling, our machines are capable of producing complex parts with the accuracy required by the semiconductor sector.

In conclusion, CNC machining plays a pivotal role in semiconductor manufacturing, enabling the industry to achieve levels of precision, miniaturization, and efficiency that were once unimaginable. As technology continues to advance, CNC machining will undoubtedly remain at the forefront of semiconductor fabrication, driving innovation and pushing the boundaries of what’s possible in this critical industry.

Advancements in CNC for Semiconductor Manufacturing

The semiconductor industry’s relentless push for miniaturization and precision has driven significant advancements in CNC technology. As we at Ethereal Machines continue to innovate and adapt, it’s essential to understand these technological strides and their implications for the future of semiconductor manufacturing.

Recent years have seen remarkable developments in CNC technology, each aiming at enhancing precision, efficiency, and versatility. Key advancements include:

- High-Precision Tooling: The introduction of ultra-precise cutting tools has allowed for even finer work at the micron level, crucial for semiconductor applications. These tools have higher durability and can maintain sharpness for longer periods, ensuring consistent quality.

- Advanced Control Systems: Modern CNC machines are equipped with sophisticated control systems. These systems offer greater accuracy in movement and positioning, vital for the intricate work required in semiconductor manufacturing.

- Improved Software for Design and Simulation: Enhanced CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software have revolutionized how components are designed and produced. They allow for more precise modeling and simulation of parts before actual production, reducing the risk of errors.

Embracing and Leading Advancements

At Ethereal Machines, we not only embrace these advancements but also contribute to their development. Our R&D team is constantly working on integrating these cutting-edge technologies into our CNC solutions, ensuring that our machines are at the industry’s forefront.

These advancements in CNC technology have profound implications for the semiconductor industry:

- Increased Precision and Consistency: With better tooling and control systems, CNC machines can produce parts with higher precision and consistency, essential for the semiconductor industry.

- Enhanced Production Efficiency: Automation and improved software reduce production times and increase throughput, allowing semiconductor manufacturers to meet growing demands more effectively.

- Innovation in Component Design: The advancements in CNC technology have expanded the possibilities in semiconductor component design, enabling more complex and efficient designs.

Conclusion

In wrapping up our exploration of CNC’s indispensable role in shaping the semiconductor industry, it becomes evident that the road ahead is brimming with exciting possibilities. At Ethereal Machines, our unwavering commitment to pushing the boundaries of CNC technology persists. We are dedicated to providing cutting-edge solutions that not only meet but surpass the rigorous demands of the semiconductor sector.

As we look toward the future, we anticipate further innovations in CNC technology, including smarter machines with AI integration, further automation, and even more precise tooling. These advancements will continue to shape the semiconductor industry, driving it towards greater efficiencies and capabilities.

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 990