The Impact of CNC Machining on Product Development Cycles

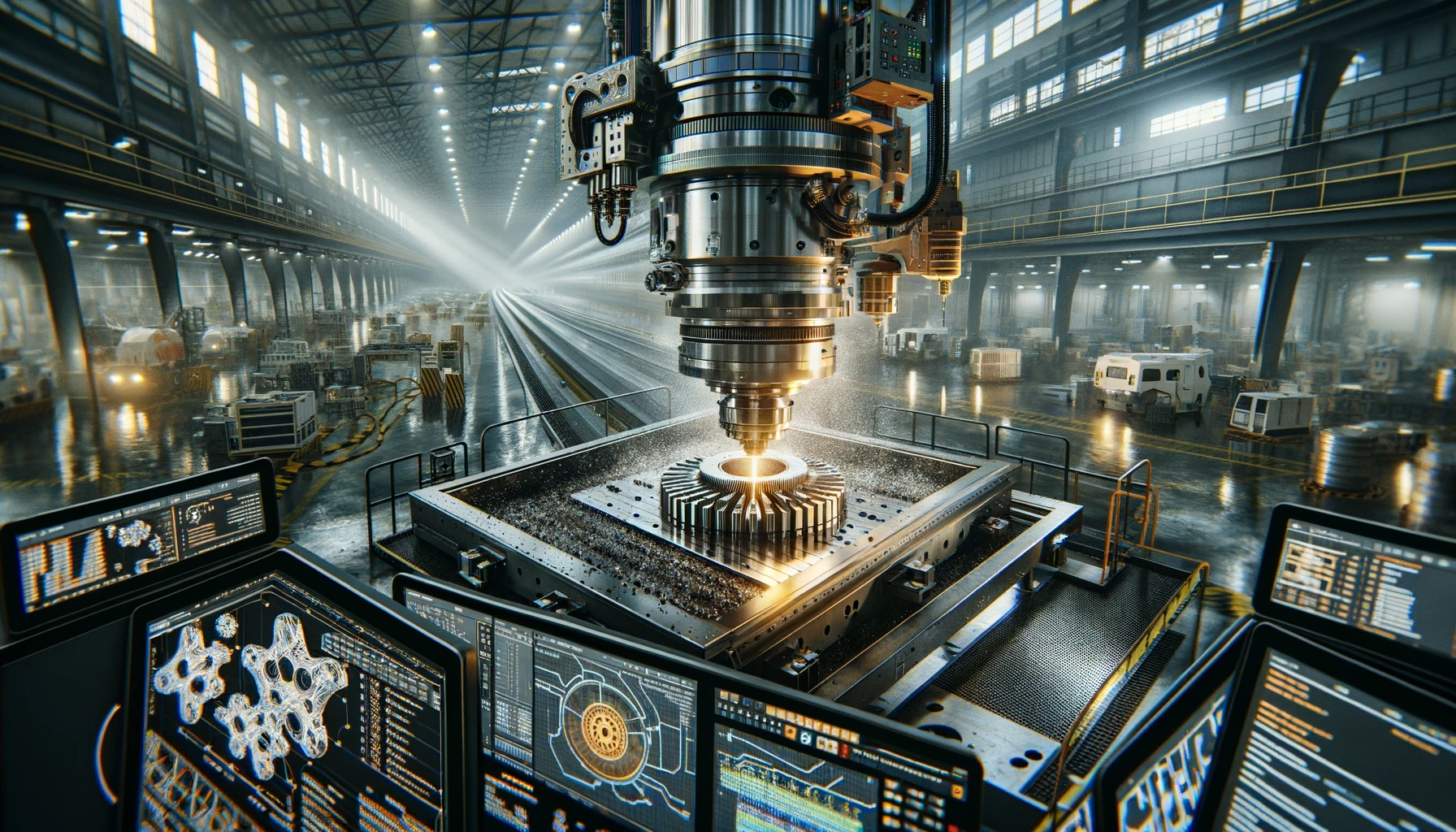

The significance of CNC machining extends beyond its technical capabilities; it fundamentally alters the product development cycle, enabling faster, more efficient, and cost-effective creation of products. From the initial concept to the final product, CNC machining integrates seamlessly into the digital workflow, bridging the gap between digital designs and physical prototypes. This integration is pivotal for industries demanding high precision and complexity in their components, such as aerospace, automotive, and medical devices.

At Ethereal Machines, we leverage CNC technology to push the boundaries of what’s possible in product development. Our expertise in CNC machining not only allows us to create intricate and precise components but also significantly accelerates the development process. This enables our clients to iterate their designs rapidly and bring their products to market faster than ever before.

Core Impact of CNC Machining on Product Development

Speed and Efficiency

One of the most significant impacts of CNC machining on product development cycles is the dramatic increase in speed and efficiency it offers. Traditional manufacturing methods often involve time-consuming processes and the manual adjustment of machines for each new component. CNC machining, however, streamlines these processes through automation, allowing for continuous operation with minimal downtime. Ethereal Machines harnesses this capability to expedite prototype production, enabling rapid iteration and refinement of designs. This swift turnaround is crucial in industries where being first to market can define success.

Moreover, the efficiency of CNC machining minimizes human error, reducing the risk of defects and rework. At Ethereal Machines, our state-of-the-art CNC equipment and expert operators ensure that every component is produced with precision, right from the first run. This not only speeds up the development cycle but also conserves resources, making the entire process more sustainable.

Precision and Consistency

CNC machining’s ability to execute complex designs with high precision is unparalleled. This precision is vital in developing modern products, which often incorporate intricate components that must fit together flawlessly. Ethereal Machines specializes in creating high-precision parts, utilizing advanced CNC machines capable of operating within tight tolerances. This ensures that every part is consistent with the CAD model, eliminating the variability seen in manual machining processes.

The consistency offered by CNC machining means that engineers and designers can push the boundaries of innovation, safe in the knowledge that their designs can be accurately brought to life. This level of precision and repeatability is essential for industries like aerospace and medical devices, where the margin for error is virtually zero.

Flexibility and Complexity

Enabling Complex Geometries

The advanced capabilities of CNC machines mean that complex designs requiring high levels of detail, which would be difficult or impractical to achieve through traditional machining or manual methods, can now be realized. This flexibility has a profound impact on product development, enabling more innovative and complex products to enter the market faster.

Ethereal Machines stands at the forefront of this innovation, utilizing our sophisticated CNC machinery to bring even the most complex designs to life. Our ability to accurately machine components with intricate geometries means that our clients can explore new design possibilities without being constrained by manufacturing limitations.

Customization at Scale

Cost Reduction Strategies

Minimizing Material Waste

Reducing Labor Costs

The Future of CNC Machining in Product Development

Conclusion

CNC machining has fundamentally transformed product development cycles, enabling faster, more efficient, and precise manufacturing. The integration of digital workflows has further enhanced this impact, making it possible to bring complex and innovative products to market quicker than ever before. At Ethereal Machines, we are proud to be at the cutting edge of this revolution, offering our clients unparalleled manufacturing solutions that drive progress and innovation.

Through our commitment to excellence and continuous improvement, we look forward to pushing the boundaries of what’s possible in CNC machining and helping our clients achieve their visions for the future.

<span data-metadata=""><span data-metadata=""><span data-buffer="">MAAS

Machining As A Service

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 735