The role of 5-Axis CNC Machining in Industry 4.0

Reshaping Manufacturing through Technological Advancements

Automation is becoming more and more popular, even in the smallest workshops. The price of 5-axis machines has fallen, allowing more stores to afford advanced equipment. Instead of needing multiple machines for a single part, workshops now only need one machine. The evolution of CNC machine services has come a long way since their inception in the 1940s. CNC machines are now used in various industries such as aerospace, electronics, nuclear, health, and medical. The automation of manufacturing processes has revolutionized production sites, with CNC machines being complex and connected to automation. However, with increased connectivity comes the need for precautions to avoid costly communication breakdowns.

Thankfully, solutions are being developed through closer relationships between software vendors, machine tool builders, and robot vendors. The future of CNC machining lies in the continuous advancement of technology, such as Industry 4.0, which includes the Industrial Internet of Things (IIoT) for autonomous monitoring and problem-solving. CNC machining will continue to push the boundaries of what is possible, particularly in precision machining. The demand for 5-axis CNC machines has also increased, thanks to their ability to handle complex parts in industries such as aeronautics, automotive, and healthcare. These machines offer improved reliability, performance, and shorter installation times. The future of CNC machining looks bright, with advanced technology driving innovation and efficiency in manufacturing processes.

The Evolution of CNC Machine Services

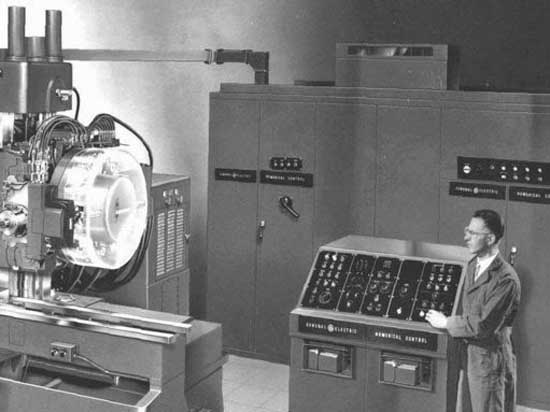

Ah, the good old’ days of the 1940s, when John T. Parsons decided to revolutionize the world of manufacturing with his invention of numerical controls for machine tools (NC). Little did he know that his brainchild would have such a profound impact on modern production.

Those numerical controls were the precursors of the CNC machines we know and love today. Parsons, driven by his quest to find solutions for aircraft parts, ingeniously paved the way for the exceptional service of present-day CNC machines. Bravo, Mr. Parsons!

Fast forward to the 1970s, a pivotal time for the advancement of CNC technology. This was when CAD/CAM made its grand entrance, bringing with it a whole new level of innovative possibilities. And let’s not forget the full introduction of CNC machines, simmering with potential. Things were really starting to heat up!

Today, CNC manufacturing has reached new heights. It’s all about smart machining, connected factories, additive manufacturing, and the fancy term, “lights-out.” Yep, the industry has gone digital, just like the whole world around us. CNC machines have become complex beasts, intricately connected to automation systems.

They’re also buddy-buddy with MRP (Manufacturing Resource Planning) systems and integrated measuring probes. But hey, with great power comes great responsibility. When multiple CNC machines start networking with each other, it’s important to tread carefully. Communication breakdowns can be a real buzzkill, costing precious time and money. We certainly don’t want those production lines grinding to a halt or sacrificing quality, now do we?

Thankfully, solutions are being developed to minimize these hiccups. It’s all about forging closer relationships between software vendors, machine tool builders, and robot vendors. With the help of smart IIoT (Industrial Internet of Things) solutions, we can nip problems in the bud before they escalate to critical levels. Phew! Crisis averted.

So there you have it, the fascinating journey of CNC machine services. From Parsons’ quest for aircraft perfection to the digital era of connected factories, CNC manufacturing continues to evolve. It’s an exciting time to be part of this ever-evolving industry. Stay tuned for more insights into the future of CNC machining!

CNC Manufacturing in the Age of Industry 4.0

In today’s manufacturing landscape, CNC machine tools have undergone significant advancements, revolutionizing the way production processes are carried out. One of the key buzzwords in this industry is “advanced manufacturing.” Gone are the days of manual operation; now, CNC machines are equipped with advanced features that allow for automation and increased efficiency. These smart machines are capable of self-diagnosing problems and correcting errors in the manufacturing process faster than human employees can even detect them. It’s like having a super-intelligent robot working tirelessly on the factory floor.

But that’s not all. The concept of connected factories has also become a reality, thanks to CNC machines. These machines can now be seamlessly integrated with manufacturing resource planning systems (MRP) and even measure and monitor processes with the help of integrated measuring probes. This level of connectivity ensures that production lines can run smoothly and efficiently with minimal human intervention.

Additive manufacturing, also known as 3D printing, has changed the game in CNC manufacturing. It allows for the creation of complex geometries and intricate designs that were previously unimaginable. With additive manufacturing, manufacturers can produce parts with reduced material waste and shorter lead times. And guess what? CNC machines are at the forefront of this revolution, making it possible to combine traditional subtractive manufacturing with additive processes. And let’s not forget the concept of “lights-out” manufacturing. No, it doesn’t involve turning off the factory lights and leaving everything in darkness. Lights-out refers to the ability of CNC machines to operate without human supervision, even during non-working hours. This means that the production process can continue uninterrupted, leading to improved efficiency and productivity.

All these advancements are part of an even bigger movement known as Industry 4.0. This movement aims to create a more complex and interconnected manufacturing setup, utilizing the Industrial Internet of Things (IIoT) to monitor and measure processes autonomously. With Industry 4.0, CNC machines have transformed into intelligent beings that can adapt to changing circumstances or fix issues before they become critical.

So, if you think CNC machining is just about cutting metal, think again. It’s a world of smart machines, connected factories, additive manufacturing, and the rise of Industry 4.0. And the best part? These advancements are not only for large-scale manufacturers but are becoming increasingly accessible to small workshops as well. The future of CNC machining is bright, and it’s time to embrace the smart, connected, and efficient manufacturing revolution.

Advancements in CNC Machining

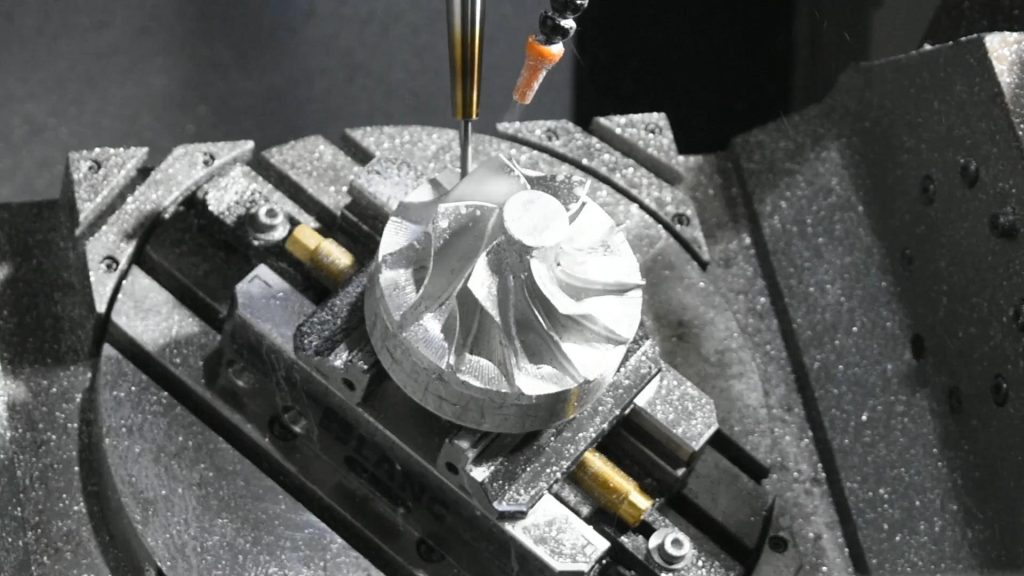

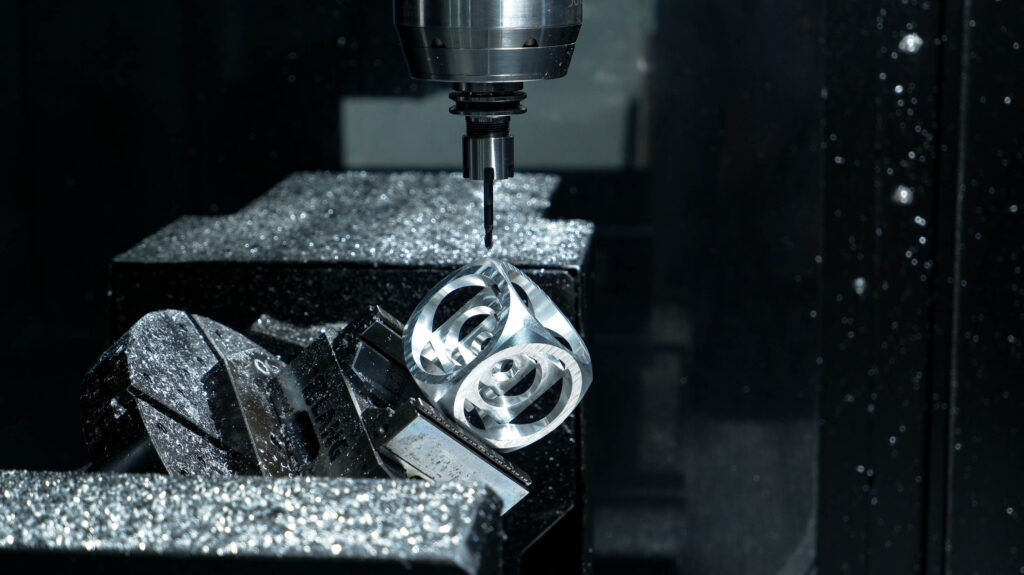

Precision CNC machining is like magic. It’s the art of crafting intricate and complex parts with utmost precision and accuracy. With the advent of advanced technology, CNC machines have taken machining to a whole new level. These machines are equipped with state-of-the-art software and hardware that can perform an array of tasks with unmatched efficiency.

Gone are the days when manufacturing was a tedious and time-consuming process. Today, CNC machines can produce parts with incredible speed and accuracy, thanks to their advanced controls and automated processes. The advancements in CNC machining have made the seemingly impossible possible.

Precision CNC machining is not limited to one industry. It has found its application in various sectors, including aerospace, automotive, electronics, and medical. These machines can fabricate components with intricate designs and tight tolerances, ensuring high-quality and flawless end products.

With precision CNC machining, manufacturers can achieve incredible efficiency, improved productivity, and cost savings. These machines eliminate the need for multiple setups and reduce the risk of human error. The result is faster production cycles and consistent quality.

In conclusion, precision CNC machining is revolutionizing the manufacturing industry. With its advanced capabilities and precision, it has opened up new possibilities for creating complex and intricate parts. As technology continues to advance, we can expect even more remarkable developments in CNC machining that will redefine the manufacturing landscape.

The Growing Demand for 5-Axis CNC Machines

The demand for 5-axis CNC machines has been on the rise lately. These machines are capable of moving a workpiece or cutting tool along five different axes simultaneously, allowing for the machining of complex parts. Industries such as aeronautics, healthcare, and automotive rely on 5-axis CNC machines to create intricate and diverse components.

But why the sudden surge in demand? Well, for starters, 5-axis CNC machines offer several advantages. They allow for single configuration machining, which means there is no need for multiple machines to produce a single part. This not only saves space but also improves efficiency.

Another reason behind the growing popularity of 5-axis CNC machines is their ability to achieve optimal cutting positions, resulting in longer tool life and improved cycle times. Suppliers are always looking for ways to reduce installation times and meet the increasing demand for machined parts.

Moreover, advancements in CNC machine controls and software have made it easier than ever to adapt to design changes and achieve the complex machines of the future. Today’s CNC machines are incredibly powerful, with PC integration becoming the norm.

So, it’s no wonder that the demand for 5-axis CNC machines is skyrocketing. These machines offer the perfect solution for industries that require precision, efficiency, and versatility. And with the constant advancements in the field, the future of CNC machining looks brighter than ever!

Benefits and Applications of 5-Axis CNC Machines

Throughout history, manufacturing has evolved and adapted to the changing needs and demands of various industries. One such advancement that has redefined the manufacturing landscape is the 5-axis CNC machine. These machines have gained popularity due to their ability to move a workpiece or cutting tool along five different axes simultaneously. And hey, who doesn’t want a machine that can multitask?

So, what are the benefits and applications of these mighty 5-axis CNC machines? Let’s dive in and explore!

First off, the 5-axis CNC machines excel in machining complex parts. This is particularly useful in industries like aeronautics, where they need to create intricate components. It’s like the CNC machine is playing a game of cat and mouse with the workpiece, maneuvering it from all angles to achieve perfection. Also, it’s important to consider the medical sector, where precision is of utmost importance. Utilizing a 5-axis CNC machine, they can fabricate components and devices that align with unparalleled precision and accuracy.

But wait, there’s more! The automotive industry is also reaping the benefits of 5- axis CNC machines. With the growing demand for diverse and advanced automotive designs, these machines come to the rescue. They can handle the ever-changing part designs and achieve optimal cutting positions, resulting in improved cycle times. Efficiency is the name of the game, folks!

And let’s not forget about the longer tool life. These machines don’t just work harder; they work smarter. With their single configuration machining capabilities, they minimize the wear and tear on the tools, extending their lifespan. It’s like having a magical tool fairy that ensures your tools stay sharp and ready for action.

By investing in 5-axis CNC machines, manufacturers can streamline their operations and reduce costs. Instead of needing multiple machines to produce a single part, they now only need one machine. It’s like having a Swiss Army knife in the workshop, versatile and efficient.

So, as we look to the future of manufacturing, it’s clear that 5-axis CNC machines will continue to play a vital role. Their ability to tackle complex parts, improve efficiency, and reduce costs makes them a must-have for industries across the board. It’s time to embrace these mighty machines and redefine the possibilities of manufacturing. Who knows what mind-blowing innovations await us on the horizon? Buckle up, because the future of CNC machining is bound to be an exhilarating ride!

The Future of CNC Machining

As CNC technology continues to advance, the future of machining looks promising. One key player in this advancement is the rise of Industry 4.0. With its complex manufacturing setup that includes the Industrial Internet of Things (IIoT), CNC machines are now able to monitor and measure manufacturing processes. They can even react autonomously when something goes wrong. Talk about machines taking over the world!

Thanks to Industry 4.0, CNC machines now have the ability to self-diagnose problems and correct errors in the manufacturing process faster than humans can. So, all those CNC machinists out there, be prepared to bow down to your new computerized overlords. They will soon be diagnosing and fixing their own issues while you’re left wondering what to do with your intricate knowledge of machining.

But don’t worry, even in this automated future, there will still be a need for human intervention. Industry 4.0 systems will require people to program and monitor them. So you won’t be entirely obsolete. You just need to be ready to embrace new roles in the business when the Industry 4.0 configuration is launched. Maybe you can become an expert in debugging CNC machines or a supervisor of robotic overlords. The future is full of exciting possibilities!

Speaking of exciting possibilities, let’s not forget about the medical industry. CNC machines, combined with Computer-Aided Manufacturing (CAM), are playing a crucial role in producing high-quality components for medical devices. Precision and flawless products are of utmost importance in this industry, as people’s lives depend on fail-safe components. With CNC machining and Industry 4.0 technology, manufacturers can ensure the production of top-notch medical devices. So, the next time you’re in need of a life-saving medical procedure, say thanks to CNC machines and don’t forget to give them a virtual high-five.

In conclusion (oops, I mean, not in conclusion), CNC machining is advancing rapidly, thanks to the power of Industry 4.0 and the integration of CAM. While automation may lead to some job displacement, there will still be a need for human expertise in programming and monitoring these intelligent machines. So, embrace the future of CNC machining and get ready to witness the rise of machines in the medical industry as well. It’s an exciting time to be a part of this ever-evolving field!

Conclusion

Manufacturing has come a long way with advancements in CNC machining and 5-axis machines. These technologies have revolutionized the industry, making it more efficient and cost-effective. CNC machines, with their numerical control systems, have paved the way for modern production. By being able to cut metal efficiently, CNC machines are useful in various industries, including aerospace, electronics, nuclear, health, and medical.

Today, CNC machine tools are complex and connected to automation, thanks to the rise of Industry 4.0. Smart machining, connected factories, additive manufacturing, and “lights-out” operations are no longer just buzzwords but have transformed into reality. These technologies, along with Industry 4.0 systems, have made it possible for CNC machines to self-diagnose and correct errors in the manufacturing process faster than ever before.

The demand for 5-axis CNC machines has also been on the rise. These machines can move a workpiece or cutting tool along five different axes simultaneously, allowing for the machining of complex parts. This is particularly valuable in industries like aeronautics and medical, where precision is crucial. Automotive manufacturers have also embraced 5-axis CNC machines to keep up with the market’s demand for diverse and advanced designs.

The future of CNC machining looks promising. Industry 4.0 will continue to play a significant role in advancing technology and automation. While the integration of these technologies may lead to job displacement, it also creates new opportunities for training and repositioning the workforce. In the medical industry, CNC machines, coupled with Industry 4.0 technology, ensure the production of high-quality components for medical devices.

In conclusion, CNC machining and 5-axis machines have redefined manufacturing by improving efficiency, precision, and capabilities. These technologies, along with the advent of Industry 4.0, have transformed the industry and will continue to shape its future. As manufacturers embrace these advancements, they open doors to new possibilities and ensure high-quality products in various sectors. So, buckle up and get ready to witness the exciting future of CNC machining!

Views: 769