The Role of G-code and M-code in CNC Milling

G-code and M-code are crucial programming languages that operators must utilize to ensure accurate and repeatable parts. Poor programming may lead to tolerance issues, poor surface finish, and other problems, so understanding the basics is key. In this blog, we’ll discuss the importance of CNC machine programming in modern manufacturing, different types of programming, and tips for successful programming. Join us as we dive into the world of CNC programming and its impact on the industry.

Basic CNC Machine Programming Methods

CNC machine programming involves three basic methods: manual programming, conversational programming, and CAM system programming.

Manual Programming requires the operator to enter the code manually, which could be tedious and time-consuming. It also requires thorough knowledge of the programming language but is an essential skill set to have. It allows quick modifications to CAM outputs and optimizes code.

Conversational Programming is an increasingly popular method that involves graphic and menu-driven functions. Operators enter commands directly into the CNC machine, similar to manual programming. This method eliminates potential issues that may arise from poor post-processors in CAM.

CAM System Programming is similar to conversational programming but more advanced. The software provides an advanced GUI with tool path strategies, eliminating the need for any manual programming.

All CNC machine programming methods involve G-code and M-code. The programming language instructs the CNC machine what to do and facilitates accurate and repeatable parts. M-codes control all the miscellaneous CNC machine functions, such as spindle rotation start and stop. Operators and programmers must check they’re inputting the correct functions before machining.

G-code and M-code

G-code is the programming language used to instruct CNC machines. G-code is a set of instructions that tell the machine where to move, how fast to move, and what path to follow. M-code, on the other hand, controls all the miscellaneous functions of the CNC machine, such as starting and stopping the spindle.

G-code is the backbone of CNC machine programming. It helps operators achieve consistent and repeatable results every time. M-code, on the other hand, makes the machine work smoothly and efficiently. CNC machines are highly customizable and complex, and one of the keys to using them effectively is understanding the G-code and M-code commands. By mastering G-code and M-code, operators and programmers can optimize their operations and reduce mistakes.

Types of CNC Machine Programming

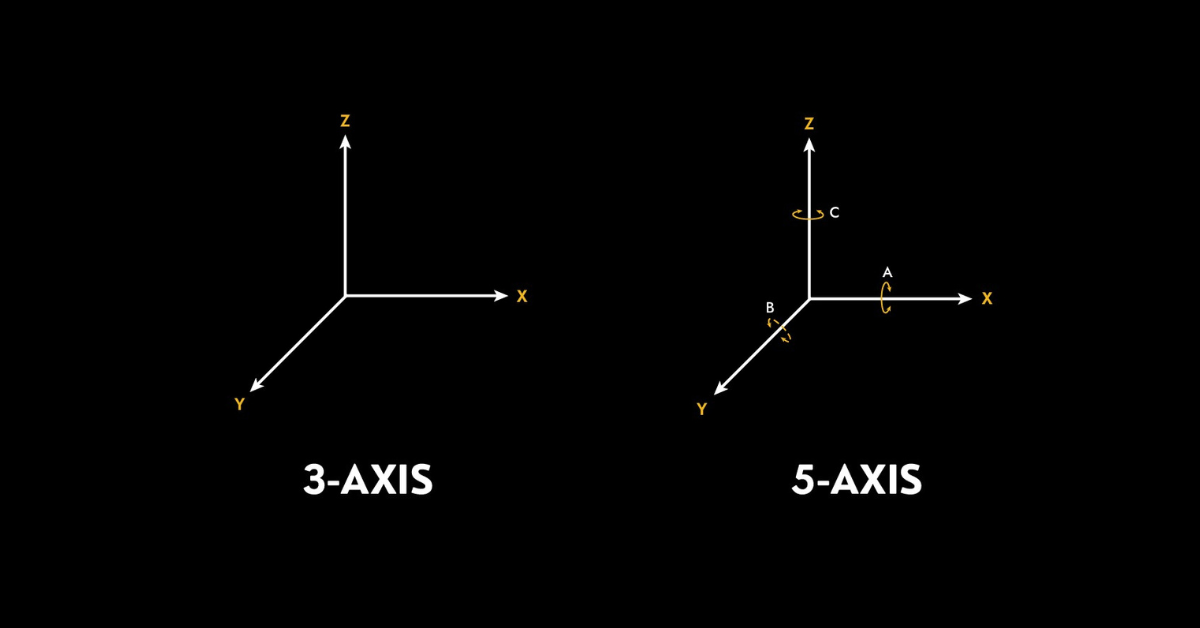

3-axis Programming

3-axis programming involves directing the cutting tool to move in 3 axes, the X, Y, and Z axes. This makes it possible to produce complex parts with intricate shapes and features.

5-axis Programming

This type of CNC machine programming is designed for advanced applications. It involves directing the cutting tool to move in all five axes, the X, Y, Z, and two rotational axes.

- A-Axis: Rotational movement around the X-axis.

- B-Axis: Rotational movement around the Y-axis.

- C-Axis: Rotational movement around the Z-axis.

Most of the 5-axis CNC machines have either XYZAC or XYZBC configuration. This programming is ideal for producing parts with complex curves and contours.

In modern manufacturing, it is essential to have an understanding of the different types of CNC machine programming and to choose the right one for the job. With suitable programming, it’s possible to create complex parts with ease and precision.

Significance of CNC Machine Programming in Different Fields

The importance of CNC Machine Programming extends beyond its use in the manufacturing industry and has trickled down to various sectors such as the Healthcare Sector, Consumer Electronics, Aerospace and Aircraft, Drone industries, and Automotive industries.

In the Healthcare Sector, CNC programming produces complex components and medical devices, including joint replacements, cranial implants, and dental restorations. The precision offered by CNC machines is essential when manufacturing medical equipment crucial to people’s lives and health.

Consumer Electronics also leverages CNC machining and its programming for optimal prototyping and production of laptops, smartphones, and other electronics. The detailed parts required for making electronics, including circuit boards, are produced with precision with the help of CNC programming.

The Aerospace and Aircraft industry benefits from CNC programming as it facilitates the production of many components and products such as propellers, wings, frames, landing gear components, and engines. CNC machines help in the creation of spacecraft like satellites and rockets, making them an important tool for the aerospace industry.

CNC machine programming plays a pivotal role in the precision-driven world of Drone manufacturing. It’s the backbone of the entire production process, ensuring accuracy and consistency in the creation of complex drone components. Take, for example, the drone’s frame. CNC programming allows for intricate designs with minimal human error, resulting in lightweight yet durable frames that enhance drone performance.

In the case of rotor blades, CNC programming optimizes their aerodynamic shape, improving flight stability and efficiency. CNC also facilitates the machining of intricate motor mounts, ensuring the precise alignment of motors, which is crucial for the drone’s balance and control.

In the Automotive manufacturing sector, parts for automobile engines, such as cylinder heads, crankshafts, camshafts, valves, brackets, and pulleys, are made by CNC programmers. Besides, CNC machines produce parts for fluid systems, suspensions, and the inside, and exterior of cars. The machines can be controlled to produce components for street automobiles, race cars, buses, and trains.

CNC machine programming is a critical skill necessary for modern manufacturing and has far-reaching importance beyond the industry. A mastery of the basics, using appropriate tools, creating a prototype, and effective debugging, are fundamental to successful CNC programming.

Tips for a Successful CNC Machine Programming

Mastering the basics of CNC machine programming is vital for producing high-quality parts consistently. Before starting a project, it’s essential to grasp manual and conversational programming methods and double-check calculations to ensure accuracy. Creating a prototype initially enables programmers to identify potential issues and refine the programming accordingly. Using appropriate tools and ensuring they are set up correctly can reduce the incidence of errors and tool damage. Effective debugging is critical for identifying and troubleshooting issues. In summary, by mastering the basics, creating a prototype, using appropriate tools, and effective debugging, operators, and programmers can produce consistent results with minimal errors.

Conclusion

In conclusion, CNC machine programming is critical in modern manufacturing as it offers improved quality and productivity over manually operated machines. With the right CNC machine programming skills and tools, manufacturers can produce precise and accurate parts in various fields, including healthcare, consumer electronics, aerospace and aircraft, and automotive. Mastering the basics of machine programming, creating a prototype, using appropriate tools, and effective debugging are some tips for successful CNC machine programming. The impact of CNC machine programming on manufacturing is immense, as it helps reduce errors, improve quality, and ultimately increase productivity.

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 296