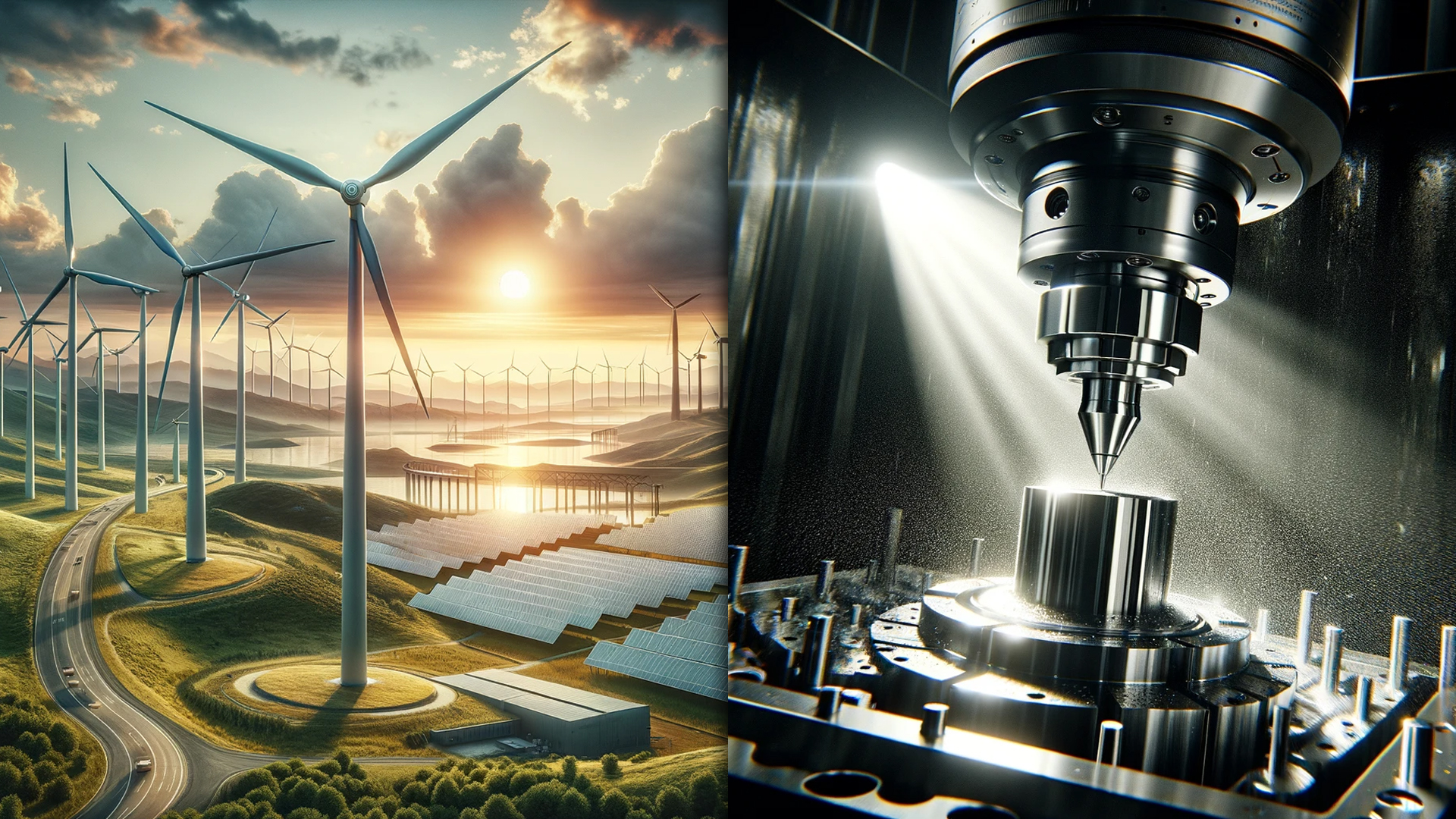

Empowering Renewable Energy: CNC Machining's Role, Opportunities, and Challenges

In deep technology, where innovation and precision are not just aspirations but necessities, CNC (Computer Numerical Control) machining stands as a cornerstone. For over a decade, this technology has revolutionized the manufacturing sector, offering unmatched accuracy, efficiency, and versatility. As we shift our focus towards a more sustainable future, the significance and necessity of CNC machining in the renewable energy sector become evident.

The renewable energy sector, abundant with potential for a cleaner, greener world, presents unique challenges and opportunities. Precision engineering is pivotal, especially in the small dimensions critical in manufacturing components for renewable energy applications. The intricacies of wind turbines, the finesse of solar panel mounts, and the robustness of hydroelectric generators all hinge on the exactitudes offered by CNC technology. This intersection of technology and sustainability underscores the importance of precision engineering in advancing the renewable energy landscape.

Opportunities in the Renewable Energy Sector

Innovation and Design Flexibility

One of the most significant contributions of CNC machining to renewable energy is the freedom it offers in design and innovation. This flexibility is crucial for customizing solutions to fit diverse environmental conditions and energy needs. For instance, the ability to quickly prototype and test various wind turbine blades or solar panel supports enables engineers to optimize designs for maximum efficiency.

- Custom Solutions for Unique Challenges: CNC machining allows for the creation of bespoke components tailored to specific renewable energy projects, whether it’s wind farms in coastal areas or solar arrays in urban settings.

- Rapid Prototyping and Testing: With CNC, prototypes can be produced swiftly, facilitating faster innovation cycles and the ability to test and refine designs in real-time cost-Effectiveness and Efficiency

CNC machining contributes significantly to reducing production costs and improving overall efficiency in the renewable energy sector. By enabling precise and efficient manufacturing processes, CNC technology minimizes waste and reduces the time and resources required for production.

- Reduced Material Waste: The precision of CNC machining means less material is wasted, contributing to both cost savings and environmental sustainability.

- Streamlined Production Processes: CNC’s automation capabilities allow for continuous, unattended operations, leading to higher productivity and lower labor costs.

Aligning with Sustainability Goals

CNC machining aligns perfectly with the sustainability goals of the renewable energy sector. By improving efficiency and reducing waste, CNC technology contributes to the eco-friendly ethos that drives renewable energy initiatives.

- Energy Efficiency in Production: CNC machines are designed to be energy-efficient, further supporting the sustainability goals of renewable energy projects.

- Long-term Reliability and Maintenance: The high quality of CNC-machined components ensures longevity and reduces the need for frequent replacements, contributing to sustainable practices.

Challenges and Solutions in CNC Machining for Renewable Energy

Navigating Complexities: Ethereal Machines’ Approach to Overcoming CNC Machining Challenges in Renewable Energy

The path to integrating CNC technology in the renewable energy sector is not without its challenges. From technical complexities to evolving industry demands, these challenges require innovative solutions and a forward-thinking approach. This section highlights the key challenges and how Ethereal Machines is positioned to address them.

Technical Challenges in CNC Machining for Renewable Energy

The renewable energy sector presents unique technical challenges for CNC machining. These include:

- Machining Complex Components: Many renewable energy components have complex geometries and require high precision. The challenge lies in consistently achieving this precision, especially for large-scale components like wind turbine blades or intricate parts like gearbox components.

- Maintaining Precision Over Large Scales: Ensuring precision in large components, such as those used in wind and hydroelectric power, is a significant challenge, given the scales involved.

Ethereal Machines addresses these challenges through a combination of advanced technology, innovation, and expertise.

- Advanced Machining Capabilities: Our state-of-the-art CNC machines are capable of handling complex geometries and large-scale components with the same level of precision as smaller parts.

- Innovative Design and Simulation Tools: We utilize cutting-edge software for design and simulation, ensuring that potential issues are identified and addressed before machining begins, thereby reducing the risk of errors.

- Expertise and Experience: Our team’s extensive experience in CNC machining for deep tech applications translates into an understanding of the unique requirements of the renewable energy sector.

Future Outlook and Continuous Improvement

The landscape of renewable energy is continuously evolving, and so are the challenges in CNC machining. Ethereal Machines is committed to continuous improvement and innovation to stay ahead of these changes.

- Investment in R&D: We continuously invest in research and development to refine our CNC machining processes and technologies.

- Adapting to Industry Trends: Keeping abreast of industry trends and advancements ensures that our solutions remain relevant and effective.

Ethereal Machines' Role and Offerings in CNC for Renewable Energy

- Customized Machining Solutions: Understanding that each renewable energy project has unique requirements, we offer customized CNC machining solutions. From small, intricate components to large, complex assemblies, our services are tailored to meet diverse needs.

- Advanced Technology Integration: Our CNC machines are equipped with the latest technology, ensuring high precision, efficiency, and reliability. This includes multi-axis machining capabilities, which are crucial for producing complex geometries required in renewable energy applications.

Product Lineup and Features

- State-of-the-Art CNC Machines: Our range of CNC machines, known for their precision and durability, are ideal for manufacturing a variety of renewable energy components. Each machine is engineered to handle different materials and component sizes, ensuring versatility and adaptability.

- Software and Automation: Alongside our hardware, we offer advanced software solutions for design, simulation, and automation. These tools streamline the production process, from concept to final product, ensuring accuracy and reducing time-to-market.

Commitment to Innovation and Quality

- Continuous Research and Development: At Ethereal Machines, we are constantly innovating, ensuring our offerings remain at the forefront of technology. Our commitment to R&D has led to breakthroughs in CNC machining, particularly in renewable energy applications.

- Quality Assurance: We maintain the highest standards of quality in all our products and services, as evidenced by our rigorous testing and quality control processes. This commitment to quality ensures that our clients receive only the best, most reliable solutions.

Conclusion

As we’ve explored, CNC machining is a driving force in renewable energy. Ethereal Machines leads this revolution, offering precision engineering and cutting-edge CNC solutions tailored to the sector’s needs. Embrace the CNC Machining Revolution with us to pioneer breakthroughs. Join Ethereal Machines today and revolutionize your renewable energy projects. Let’s shape a brighter, more sustainable future together.

Contact us now to learn how our CNC machining solutions can elevate your projects to new heights. Together, let’s innovate, optimize, and propel the renewable energy industry forward.

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 284