CNC Machining in Plastic Industry & Importance of 5-Axis Machining Technology

The most economical and efficient technology for high-speed manufacturing of lesser than ten plastic models or prototypes is called the Subtractive method or CNC machining. Subtractive method, because it involves the removal of material.

Plastic CNC machining uses digital milling machines to manufacture plastic product parts in the mass of a plastic block. The functional testing environment is best suited for high-speed prototyping technology for unit production. The product part is from a wide variety of resins that help manufacture the plastic part of the product of the suitable material.

CNC machining does not use molds, thus reducing costs. The machines manufacture several identical parts of the same quality. The metals and thermoplastics used in production facilitate the making of products of the desired physical properties.

Impact and Size — Plastic Industries Contribution to the World Economy

Globally the size of the plastic market in 2020 is approximately USD 579.7 Billion. From 2021 to 2028, the estimated compound annual growth rate (CAGR) of 3.4%. The increase in demand for plastic from the automotive, electrical, constitutional, and electronic industries supports the growth in the market.

Regulations to increase fuel efficiency by decreasing the weight of vehicles reduces the harm to the environment through harmful carbon emissions. That encourages manufacturers to switch to plastic parts rather than steel or aluminum in automobile manufacture.

There is an emerging trend for plastic in the construction industry in countries like Brazil, Mexico, India, and China that has further spiked up production. The need for better public and industrial infrastructure has led to the easing of FDI norms. That has contributed to an increase in foreign investment and the growth of the plastic market.

The demand for plastic decreased due to the pandemic. That is because the industries that use plastic, cut down their production to curtail the disease. But the need for testing kits, gloves, ventilators, etc., to combat the disease saw a rise in demand for plastic.

The Indian plastic industry has grown significantly since its inception in 1957. There has also been a speedy diversification in the industry. It employs more the 4 million people across the country with more than 30,000 processing units. Of these, 85-90% are small or medium enterprises.

What Is the Scope of CNC Machining in the Plastic Industry?

CNC machining can process any material and has unlimited applications that aid several industries, and various applications use it. It works for direct, indirect processes of manufacturing and in collaboration with other procedures. CNC plastic machining technologies have led to sophisticated plastic milling machines that are indispensable for multi-sided machining. The process completes complex parts of low volume in a single setup reducing time and saving energy.

Plastic CNC milling is distinct in its benefits over injection molding, 3D printing, and rapid prototyping. It works with a wide variety of materials with tight tolerance and is economical. CNC machining prototype productions are not limited in their use in one sector.

Scope of CNC Machining in Various Industries

Aerospace

Automotive Industry

Consumer Electronics

Notable Applications of Plastic Machining

Plastic machining offers more merits than demerits. Manufacturers opine that it is the best alternative to create a wide variety of parts and products like:

1. Equipment for use in the laboratory and other scientific purpose

2. Equipment to handle chemicals.

3. Food package and handling.

4.Components of semiconductors.

5. Photonics.

6. Microelectronics.

7.Devices for biomedical and pharmaceutical

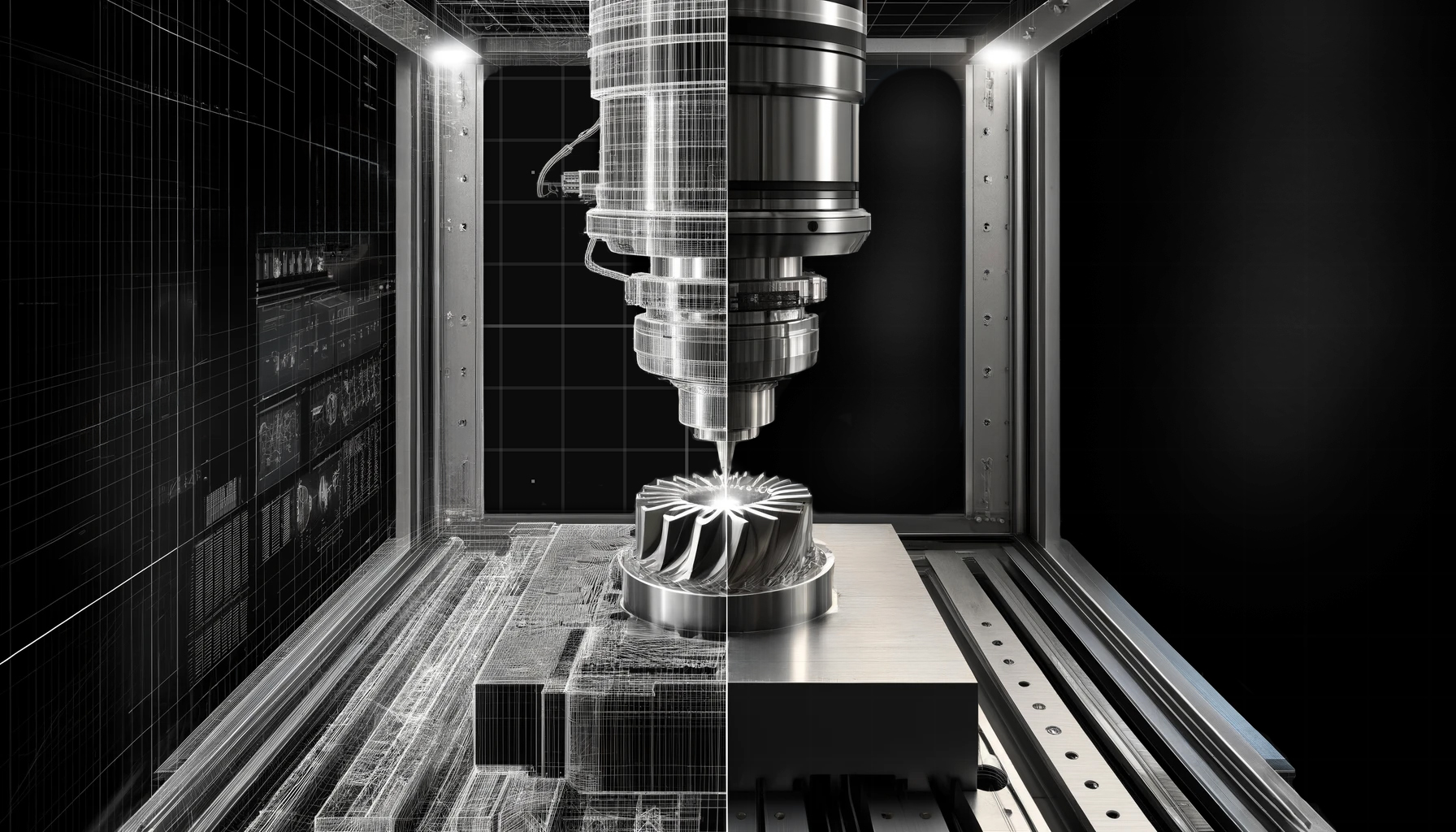

The importance of 5-axis CNC machining in the plastic industry is not much understood because they are rare. They work on 5 out of the 6 axes coordinate systems in the same setup. To put it simply, the machine in one setup — can work on 5 sides of a product part. Only the base will be left out.

The noteworthy part about this is all the 5 axes work together simultaneously. It works to remove material on each surface of the product part other than the base and the clamping area. While the 3 axis machine does the process in multiple setups and manually operated rotations, the 5 axis does it in the same configuration.

CAM software can program the 5 axis machines. The recently manufactured machines are made with better technology and are easy to use. The machine costs more than the other machine but does the work faster, thus breaking even.

Benefits of the 5-Axis Machines

5-axis CNC Machines work with the highest precision with multidimensional rotation to work on all sides of the workpiece. It is preferred to produce components that need intricacy and detailing.

Increases the Life of the Machine

Better Surface Finish

Complex Parts Made Sooner

Works on Complex Contours Efficiently

They Provide a Higher Rotational Accuracy

Conclusion

Views: 97