Digital Twin Technology in CNC Machining

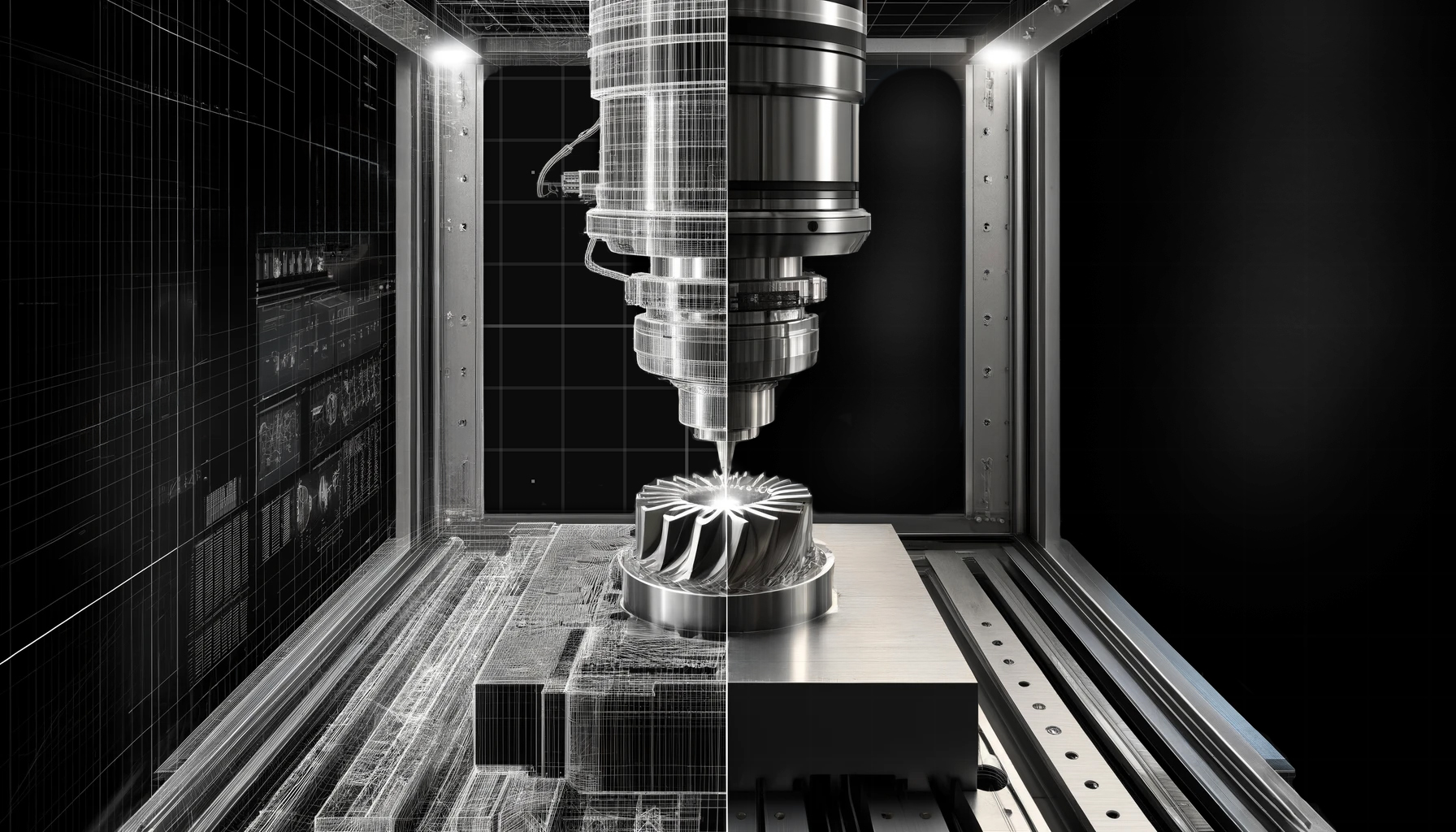

Digital twin technology is transforming the manufacturing landscape, offering unprecedented precision and efficiency in CNC machining. As industries increasingly adopt digitalization, digital twins have emerged as a critical tool in bridging the gap between physical and virtual environments. A digital twin is a virtual replica of a physical entity, created through the integration of data, sensors, and advanced modeling techniques. This technology enables real-time monitoring, simulation, and optimization of manufacturing processes, significantly enhancing the capabilities of CNC machines.

In the CNC machining industry, digital twin technology is revolutionizing how parts are designed, manufactured, and maintained. By creating a dynamic, real-time digital counterpart of a physical machine or component, manufacturers can predict performance issues, optimize operations, and ensure product quality with remarkable accuracy. This not only reduces downtime and operational costs but also paves the way for more innovative and complex designs.

What is Digital Twin Technology?

The Process of Digital Twin Technology and How It Works

Step 1: Initial Setup Requirements

Data Collection and Sensor Integration

Infrastructure Setup

Establishing a robust IT infrastructure is essential for managing the data flow between the physical machine and its digital counterpart. This includes secure network connections, data storage systems, and cloud-based platforms for data processing and analysis.

Step 2: Data Acquisition and Real-Time Synchronization

Continuous Data Collection

Data Streaming and Synchronization:

Step 3: Digital Model Creation and Simulation

Building the Digital Model

Simulation of Machining Processes

Step 4: Calibration and Ongoing Maintenance

Calibration of Digital Twin

Predictive Maintenance

Step 5: Optimization and Continuous Improvement

Real-Time Monitoring and Optimization

Feedback Loop

Benefits of Digital Twin Technology

Real-Time Monitoring and Predictive Maintenance

Reduced Downtime and Optimized Performance

Improved Product Quality and Consistency

Specific Use Cases in CNC Machining

Aerospace

Aerospace manufacturing demands unparalleled precision and reliability in manufacturing components. Digital twin technology enables aerospace manufacturers to create detailed simulations of complex parts, optimizing machining processes to achieve exact specifications.

Using digital twins to manufacture turbine blades with intricate geometries allows for the simulation of the machining process and adjustment of parameters in the digital model. This can result in a significant reduction in material waste and an improvement in surface finish quality.

Healthcare

In the healthcare sector, the production of medical devices requires stringent quality control and adherence to regulatory standards. Digital twins allow manufacturers to monitor and control every aspect of the machining process, ensuring compliance and high product quality.

A healthcare device manufacturer producing precision components for surgical instruments can use digital twin technology to identify and correct potential defects in the digital model, leading to an increase in production yield and a reduction in time-to-market.

Drones

The drone industry benefits from digital twin technology by optimizing the design and manufacturing of lightweight and high-strength components. Digital twins help in simulating the performance of drone parts under various conditions, ensuring durability and efficiency.

Utilizing digital twins to manufacture custom drone parts helps optimize the weight-to-strength ratio, potentially increasing flight efficiency and reducing production costs.

Electronics

The electronics industry requires high precision and consistency in manufacturing small and complex components. Digital twin technology enables real-time monitoring and control of the machining process, ensuring high quality and reducing the likelihood of defects.

An electronics manufacturer using digital twins to produce intricate circuit board components can predict and mitigate potential issues, leading to a reduction in defect rates and an increase in production speed.

General Engineering

In general engineering, digital twins facilitate the production of custom parts with high precision and efficiency. They enable engineers to test and refine designs in the virtual space before actual manufacturing, reducing trial-and-error and improving overall productivity.

Implementing digital twin technology to produce bespoke machine parts allows for precise simulations and optimizations, which can lead to an improvement in machining accuracy and a decrease in lead times.

Future Trends in Digital Twin Technology

Integration of Artificial Intelligence and Machine Learning

- Enhanced Predictive Capabilities: The integration of AI and machine learning with digital twin technology is set to revolutionize predictive maintenance and operational optimization. By analyzing vast amounts of data, AI algorithms can identify patterns and predict potential issues with greater accuracy, enabling more proactive and efficient maintenance strategies.

- Autonomous Optimization: Machine learning models can continuously learn from data generated by digital twins, autonomously optimizing machining processes in real time. This leads to improvements in efficiency, precision, and overall productivity without human intervention.

IoT Connectivity and Real-Time Data Analytics

- Seamless Data Flow: The Internet of Things (IoT) facilitates seamless connectivity between physical machines and their digital counterparts. This real-time data exchange ensures that digital twins are always up-to-date, providing accurate and timely insights into machine performance and health.

- Advanced Analytics: The combination of IoT and digital twins enables advanced data analytics, offering deeper insights into machine operations. Manufacturers can leverage this data to make informed decisions, enhance process efficiency, and improve product quality.

Advancements in Simulation Technologies

- High-Fidelity Simulations: Future advancements in simulation technologies will enable the creation of even more accurate and detailed digital twins. High-fidelity simulations will allow manufacturers to model complex machining processes and predict outcomes with greater precision.

- Virtual Testing and Validation: Enhanced simulation capabilities will facilitate virtual testing and validation of new designs and processes. Manufacturers can experiment with different scenarios and configurations in the digital realm, minimizing the need for physical prototypes and reducing development time and costs.

The Evolving Role of Digital Twins in Industry 4.0

- Smart Manufacturing: Digital twins are at the forefront of the Industry 4.0 revolution, driving the transition to smart manufacturing. By integrating digital twins with other Industry 4.0 technologies, such as AI, IoT, and robotics, manufacturers can create highly automated and intelligent production environments.

- Sustainable Manufacturing: Digital twin technology can also contribute to more sustainable manufacturing practices. By optimizing resource usage and reducing waste, digital twins help manufacturers minimize their environmental impact and achieve sustainability goals.

Potential Impacts on the CNC Machining Industry

- Increased Competitiveness: Manufacturers that adopt digital twin technology will gain a competitive edge by achieving higher efficiency, precision, and product quality. This technology will enable them to meet the growing demands of customers and stay ahead in a rapidly evolving market.

- Innovation and Customization: Digital twins will drive innovation and enable greater customization in CNC machining. Manufacturers can experiment with new designs and processes in the digital realm, bringing innovative products to market faster and more efficiently.

Conclusion

Digital twin technology is a transformative force in the CNC machining industry, offering unparalleled precision, efficiency, and operational excellence. By creating a dynamic, real-time digital replica of physical machines, manufacturers can optimize processes, predict and prevent issues, and ensure the highest quality standards. From aerospace to healthcare, drones to electronics, and general engineering, the applications and benefits of digital twin technology are vast and impactful.

Looking forward, the integration of AI, machine learning, IoT, and advanced simulation technologies will further elevate the capabilities of digital twins. These advancements will drive the next wave of innovation in CNC machining, contributing to smarter, more efficient, and sustainable manufacturing practices. Embracing digital twin technology is not just a step forward; it’s a leap into the future of manufacturing.

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 1006