The Significance of Engine Components in Aerospace:

Advanced Machining Techniques for Aerospace Components:

Complex Aerospace Components Made Possible:

Here are a few Aerospace CNC machined components with the Challenges in manufacturing those components and the advantages involved in machining those components in CNC 5-axis machine:

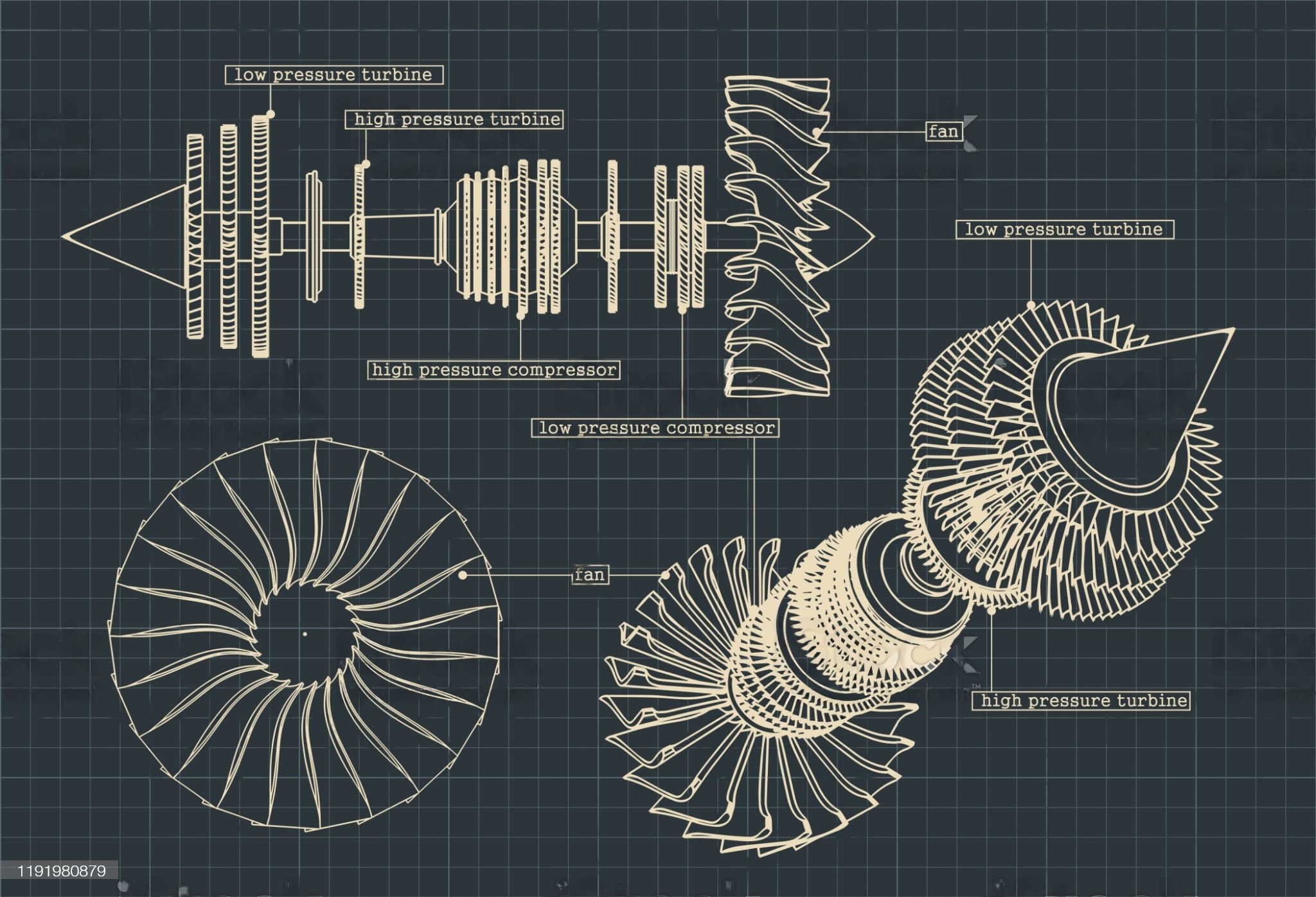

Turbine Blades

Challenges: Manufacturing turbine blades with intricate airfoil shapes require precise machining capabilities to achieve the desired aerodynamic performance.

Advantages: CNC 5-axis machines offer the necessary flexibility and precision to produce complex airfoil shapes, ensuring optimal aerodynamics and performance. The versatility of 5-axis machining enables the machining of curved profiles and intricate blade features.

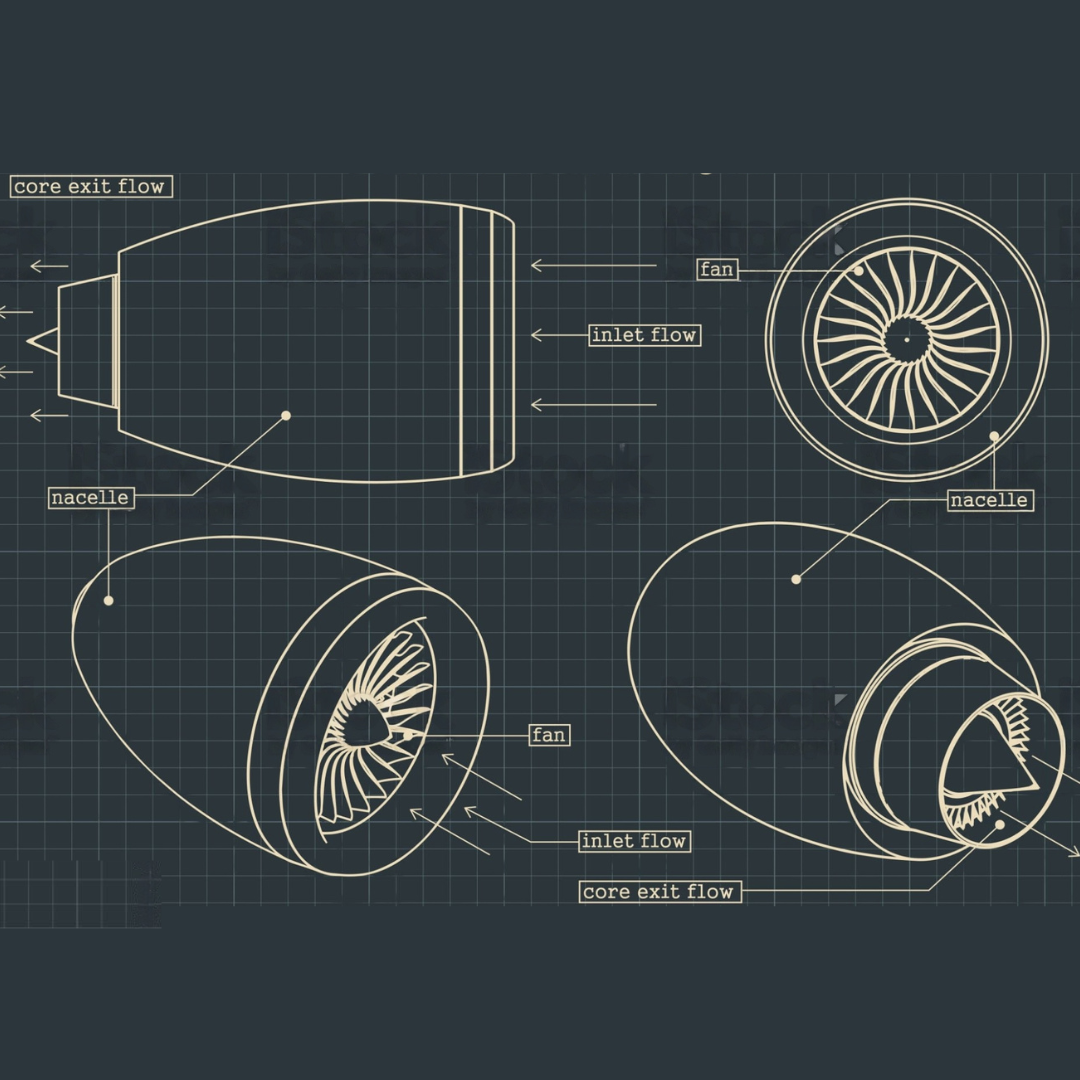

Engine Housings

Challenges: Engine housings often require the machining of complex internal cavities and cooling channels, posing challenges in terms of tool accessibility and precise machining of intricate features.

Advantages: CNC 5-axis machines provide the capability to reach deep and intricate areas within engine housings, ensuring the precise machining of internal cavities and cooling channels. The simultaneous multi-axis movement allows for complex geometries and optimal cooling system designs.

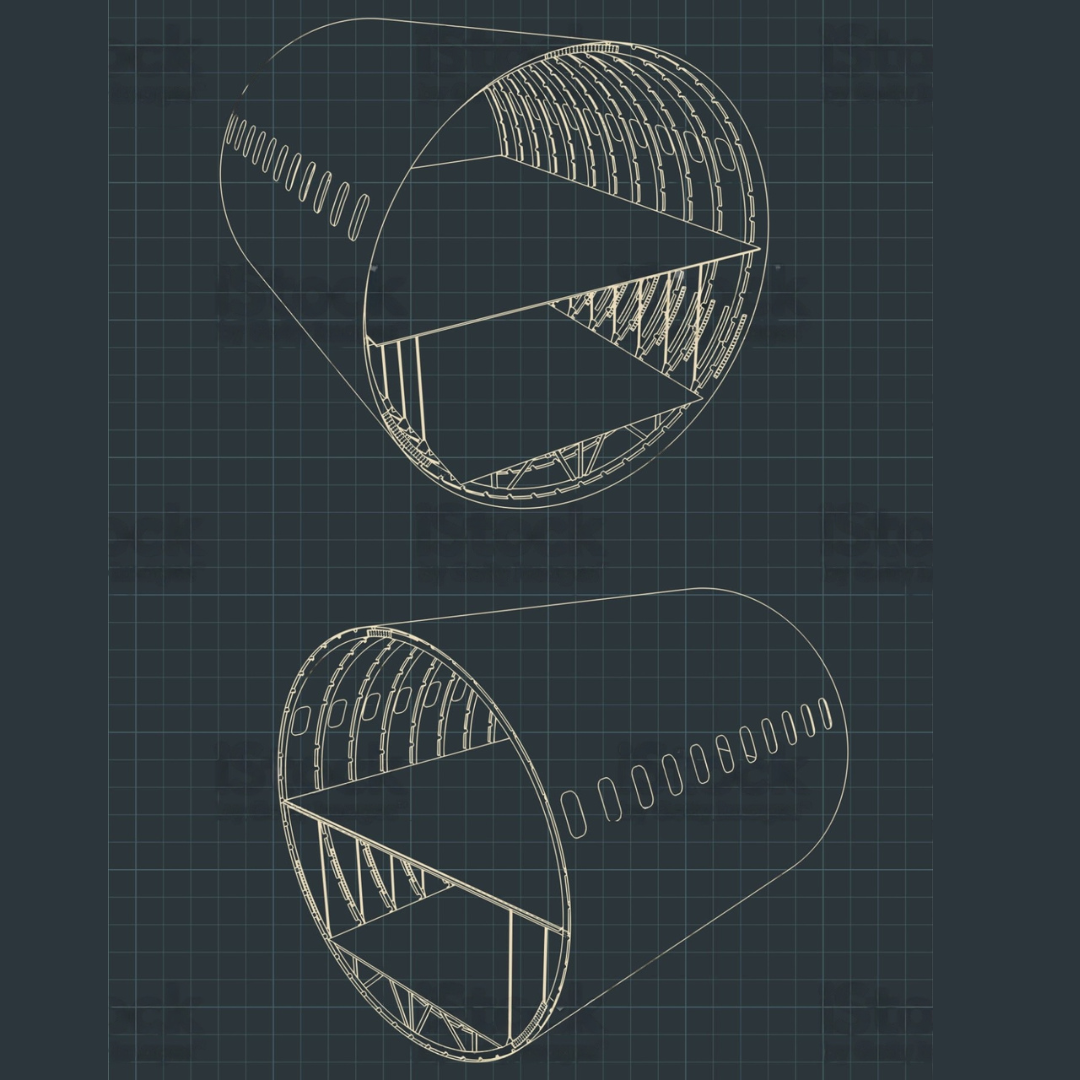

Structural Components

Challenges: Manufacturing intricate structural components with high strength-to-weight ratios requires precise machining of complex geometries and the selection of suitable materials.

Advantages: CNC 5-axis machines excel in machining complex shapes, allowing for the production of intricate structural components. The advanced machining capabilities enable precise material removal, resulting in components with optimal strength-to-weight ratios.

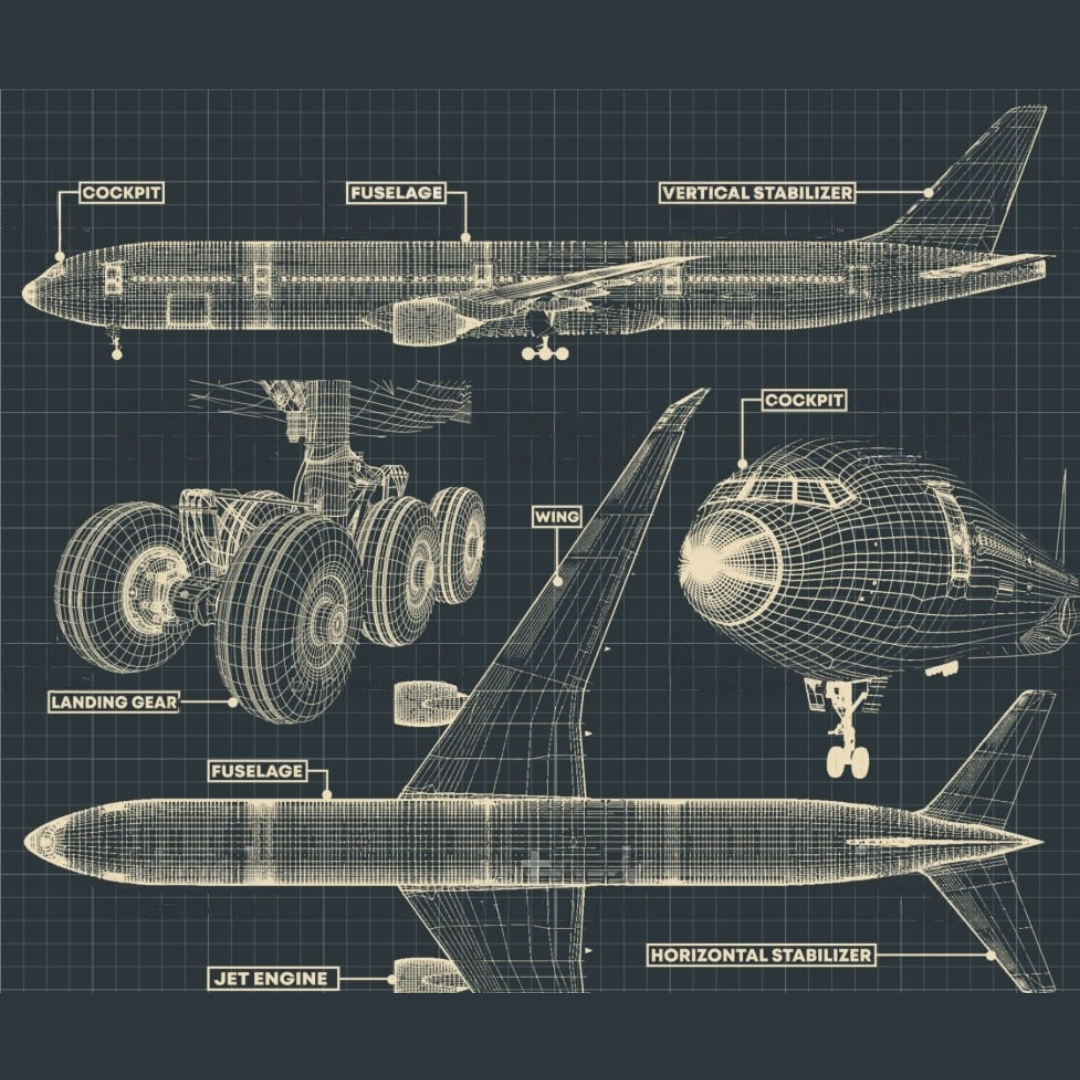

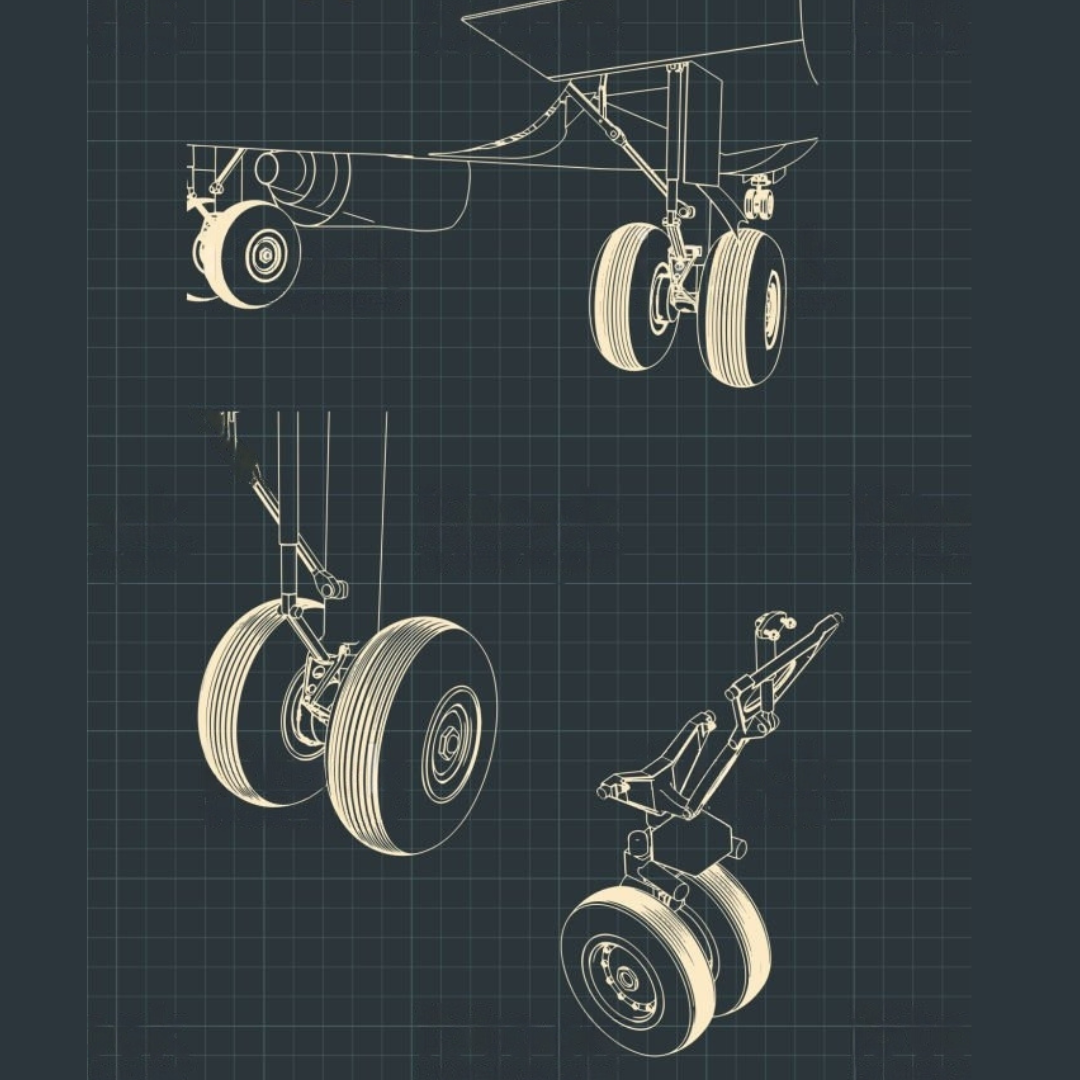

Landing Gear Components

Challenges: Landing gear components often have complex geometries, including intricate profiles and features that require precise machining for strength and durability.

Advantages: CNC 5-axis machines provide the versatility to accurately machine complex landing gear geometries. The simultaneous movement of multiple axes ensures the precise machining of intricate features, resulting in landing gear components that meet stringent strength and durability requirements.

Ensuring Safety and Reliability:

Quality Control and Inspection: Implementing a robust quality control system is essential to verify the accuracy and integrity of each component. This involves conducting thorough inspections at various stages of the manufacturing process, including pre-machining, post-machining, and final inspection. Advanced inspection techniques such as coordinate measuring machines (CMMs) and non-destructive testing (NDT) methods can be employed to detect any defects or deviations from specifications.

Material Traceability: Maintaining proper material traceability is vital in the aerospace industry. Each component should be traceable back to its source material, including the specific alloy or material grade used. This ensures that the materials used meet the required specifications and have the necessary certifications. Material traceability also facilitates effective quality control and enables quick identification and resolution of any issues that may arise.

Documentation and Record-Keeping: Accurate and comprehensive documentation is essential to track the entire manufacturing process and ensure traceability. This includes maintaining records of material certifications, machining parameters, inspection reports, and any modifications or repairs made during the process. Proper record-keeping allows for easy identification of any potential issues and facilitates effective corrective actions if required.

Testing and Validation: After CNC machining, it is crucial to subject the components to rigorous testing and validation procedures. This may include functional testing, stress testing, fatigue testing, and environmental testing to simulate real-world operating conditions. These tests help verify the performance, durability, and reliability of the components, ensuring they meet the required standards and specifications.

Collaborative Partnerships and Industry Expertise:

At Ethereal Machines, we take immense pride in our role as a deep-tech parts manufacturer, driving aerospace innovation and performance through precision machining. With our expertise, advanced technologies, and unwavering commitment to quality, we continue to establish credibility as trusted partners in the aerospace industry. Together, let us shape the future of aerospace engineering by delivering precision, reliability, and excellence in every engine component we manufacture.

Views: 396