Choose the Right CNC Partner: ISO9001 & AS9100D Certifications

So, you’re on the hunt for a CNC machining service partner. It’s an exciting endeavor, but before you get dazzled by glossy brochures and flashy websites, let’s talk about something that truly matters – certifications. Yes, those certificates that might seem like mere pieces of paper but hold significant weight in the world of precision manufacturing.

In this article, we’ll take a deep dive into the importance of ISO 9001 and AS 9100D certifications when selecting your CNC machining service partner. We’ll explore what these certifications signify, how they benefit you, and why they should be at the top of your checklist. Trust us; it’s about more than just finding someone who can make impressive parts. Certifications matter, and they matter a lot!

So, fasten your seatbelt as we embark on a journey to understand why these certifications are more than flashy badges – they’re your assurance of a reliable CNC machining partner.

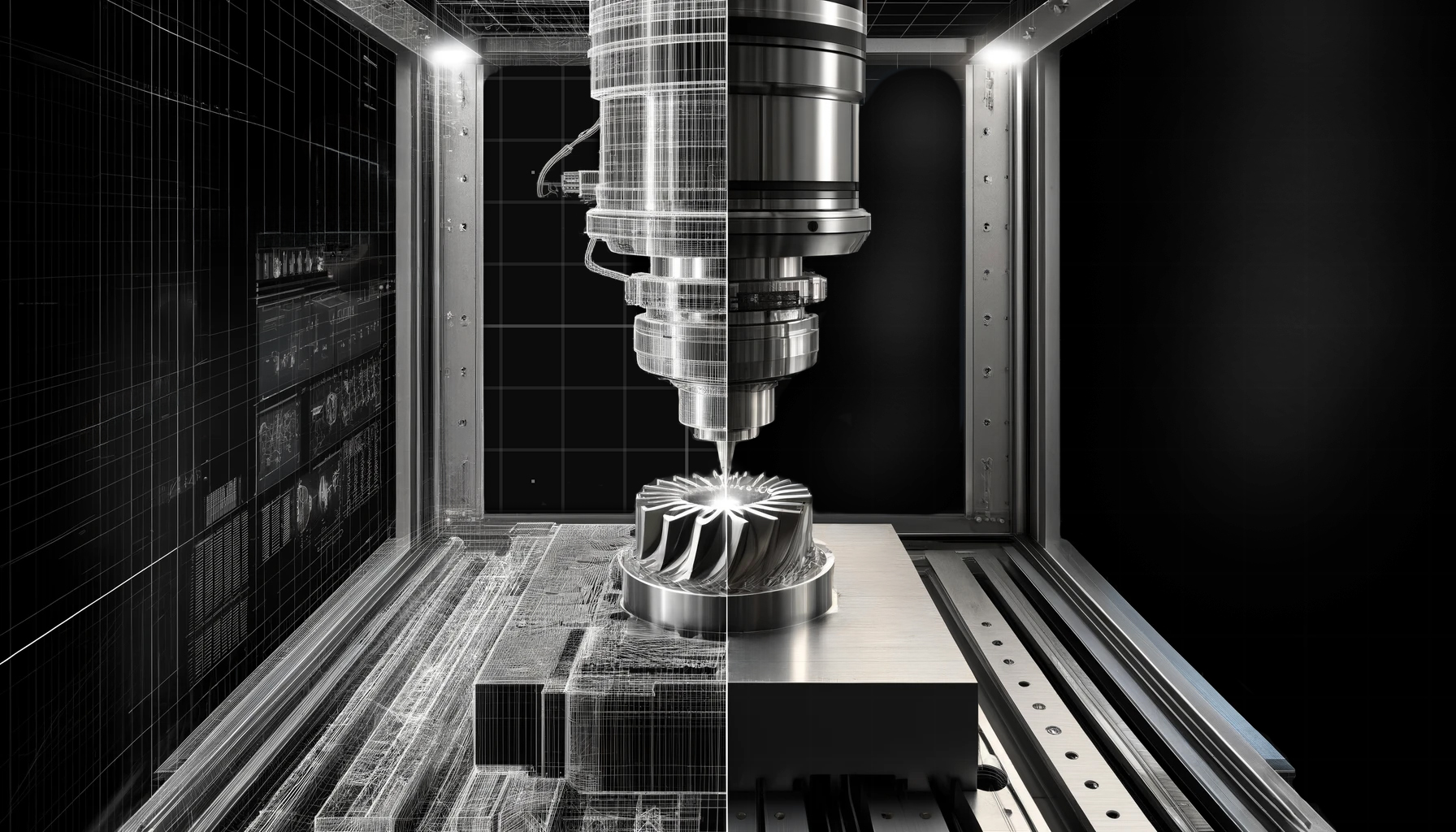

Understanding CNC Machining

The Significance of ISO 9001 Certification

Now that we’ve scratched the surface of CNC machining, let’s delve into why ISO 9001 certification matters in your selection of a CNC machining service partner.

ISO 9001 certification isn’t just a fancy title; it’s a mark of quality and competence in the realm of CNC machining. This internationally recognized standard ensures that a company adheres to defined processes and procedures to consistently deliver top-notch products and services. Think of it as a seal of approval from the quality control deities.

The crux of ISO 9001 is the Quality Management System (QMS). To earn and maintain this certification, a company must have a well-established QMS in place. This means that every facet of their operations, from design to delivery, is meticulously documented, monitored, and controlled. No stone is left unturned in ensuring that every product leaving their facility meets the highest quality standards.

But why should you care about ISO 9001 certification when selecting a CNC machining service partner? Here’s the lowdown:

Quality Assurance: ISO 9001 certification guarantees that the company you choose has a robust quality control process. You won’t have to worry about receiving subpar products that disintegrate at the slightest touch. ISO 9001 certification means quality is a top priority.

Commitment to Improvement: Obtaining and keeping ISO 9001 certification necessitates constant evaluation and enhancement of processes. This means the company is perpetually striving to deliver better products and services to their customers. Who doesn’t want a partner dedicated to continuous improvement?

Customer Confidence: When you spot ISO 9001 certification, it instills confidence in customers. It assures you that the company has undergone rigorous audits and assessments to prove their competence. It’s like having a trusty sidekick by your side, ensuring that your CNC machining needs are in capable hands.

In the world of CNC machining, where precision reigns supreme, ISO 9001 certification is your golden ticket to quality, continuous improvement, and customer satisfaction. Remember, in CNC machining, precision is non-negotiable, and ISO 9001 certification guarantees exactly that.

AS 9100D Certification for the Aerospace Industry

Now that we’ve tackled ISO 9001, let’s soar into the realm of AS 9100D certification, particularly significant in the aerospace industry.

AS 9100D certification is a specialized certification designed for aerospace companies, ensuring they meet the highest quality standards. It builds upon the ISO 9001 standard but incorporates additional requirements tailored specifically to the aerospace industry. So, if your CNC machining service partner holds this certification, it signifies that they’ve undergone rigorous processes to meet industry-specific demands.

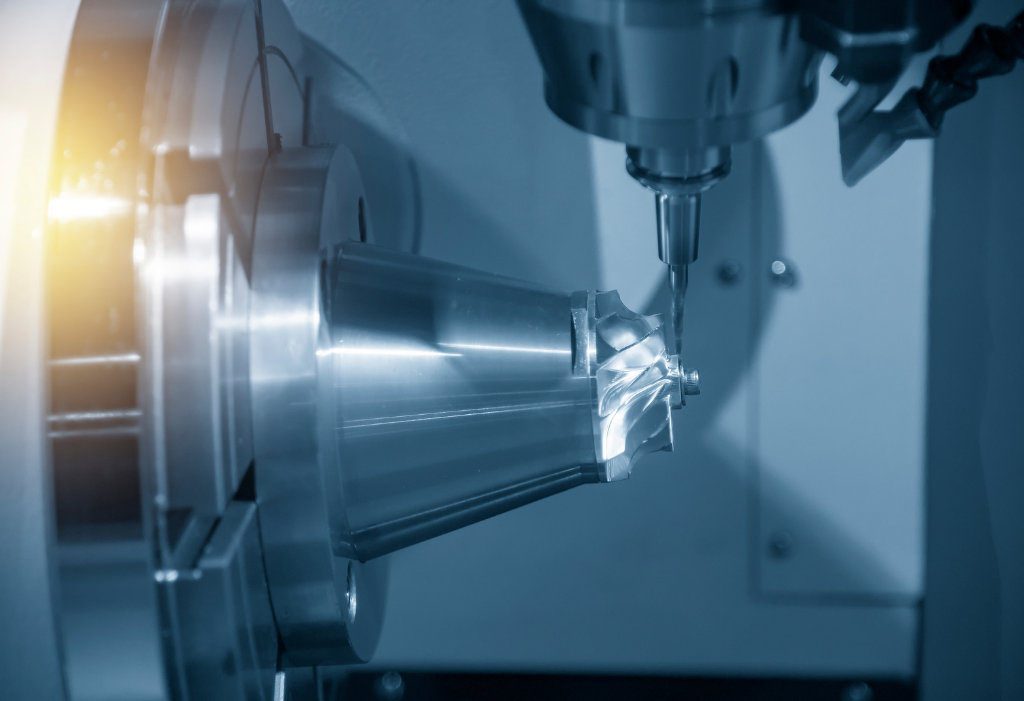

What are these specific aerospace requirements, you ask? In aerospace, precision and reliability are paramount. The tiniest error or defect can have catastrophic consequences. AS 9100D certification focuses on areas like risk management, configuration management, and traceability. It ensures CNC machining service partners have robust processes in place to prevent errors, track changes, and maintain quality control throughout the manufacturing process.

Discover the pivotal role of AS 9100D Certification in aerospace CNC

- Industry Stamp of Approval: AS 9100D certification is akin to a stamp of approval from the aerospace industry itself. It signifies that a CNC machining service partner possesses the expertise, knowledge, and systems needed to meet the rigorous requirements of aerospace manufacturing. It assures you they can deliver high-quality components adhering to the aerospace industry’s stringent standards.

- Technology Prowess: The aerospace industry thrives on cutting-edge technologies. When a CNC machining service partner holds AS 9100D certification, it indicates their commitment to staying updated and continuously improving their processes. They’re leveraging the latest technologies and techniques to excel. In essence, they’re a reliable, forward-thinking partner.

Choosing a CNC Machining Service Partner

Now that we’ve dissected the importance of ISO 9001 and AS 9100D certifications, let’s navigate the critical terrain of selecting the ideal CNC machining service partner. It’s not just about certifications; several key factors come into play.

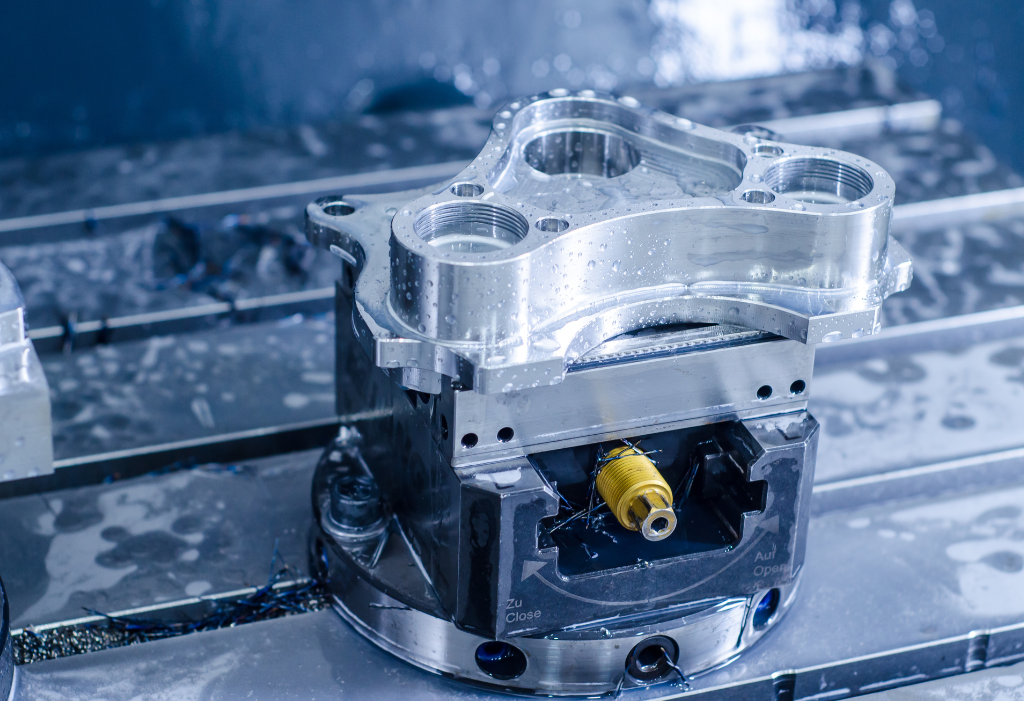

- Capabilities and Expertise: Assess the capabilities and expertise of the CNC machining company you’re considering. Do they have the necessary equipment and technical know-how to handle your specific machining requirements? You want a partner capable of adapting to various industries and handling a wide range of projects.

- Quality Management System: Investigate the company’s quality management system. Look for ISO 9001 certification, which ensures stringent quality standards. It’s your guarantee that they’ve implemented effective quality control processes and are committed to continuous improvement.

- Emphasis on Continuous Improvement: Seek a CNC machining service partner that prioritizes continuous improvement. Do they show a commitment to staying ahead of the curve and enhancing their processes and technologies continuously? This ensures they can deliver even better results with each project, adapting to the evolving needs of the industry.

- Certifications: Certifications serve as vital parameters when evaluating a CNC machining service partner. While ISO 9001 is a general certification, consider specialized certifications like AS 9100D for the aerospace industry. These certifications demonstrate the company’s commitment to meeting the specific requirements and quality standards of the industry they serve.

- Real-World Results: Beyond certifications, examine real-world results. Case studies and customer reviews provide insights into the CNC machining service partner’s previous projects and customer satisfaction levels. It helps you gauge their track record and ensures they can deliver on their promises.

In conclusion, choosing the right CNC machining service partner is a multifaceted endeavor. Assess capabilities and expertise, scrutinize the quality management system, emphasize continuous improvement, and consider certifications, and review case studies and customer feedback. By following these guidelines, you can find a reliable and competent partner who will meet your CNC machining needs with precision and excellence.

Conclusion

Choose Ethereal Machines as your CNC machining partner, and you’ll experience unmatched precision and quality. Prioritize certifications like ISO 9001 and AS 9100D when selecting your partner for a commitment to excellence.

In conclusion, these certifications symbolize competence and dedication to quality. Your CNC machining dreams are attainable with the right partner. Join us on this journey towards unparalleled excellence. Your success is our mission. Thank you for choosing Ethereal Machines as your CNC service provider. Stay connected for updates and let’s shape an inspiring future together. Happy machining!

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 274