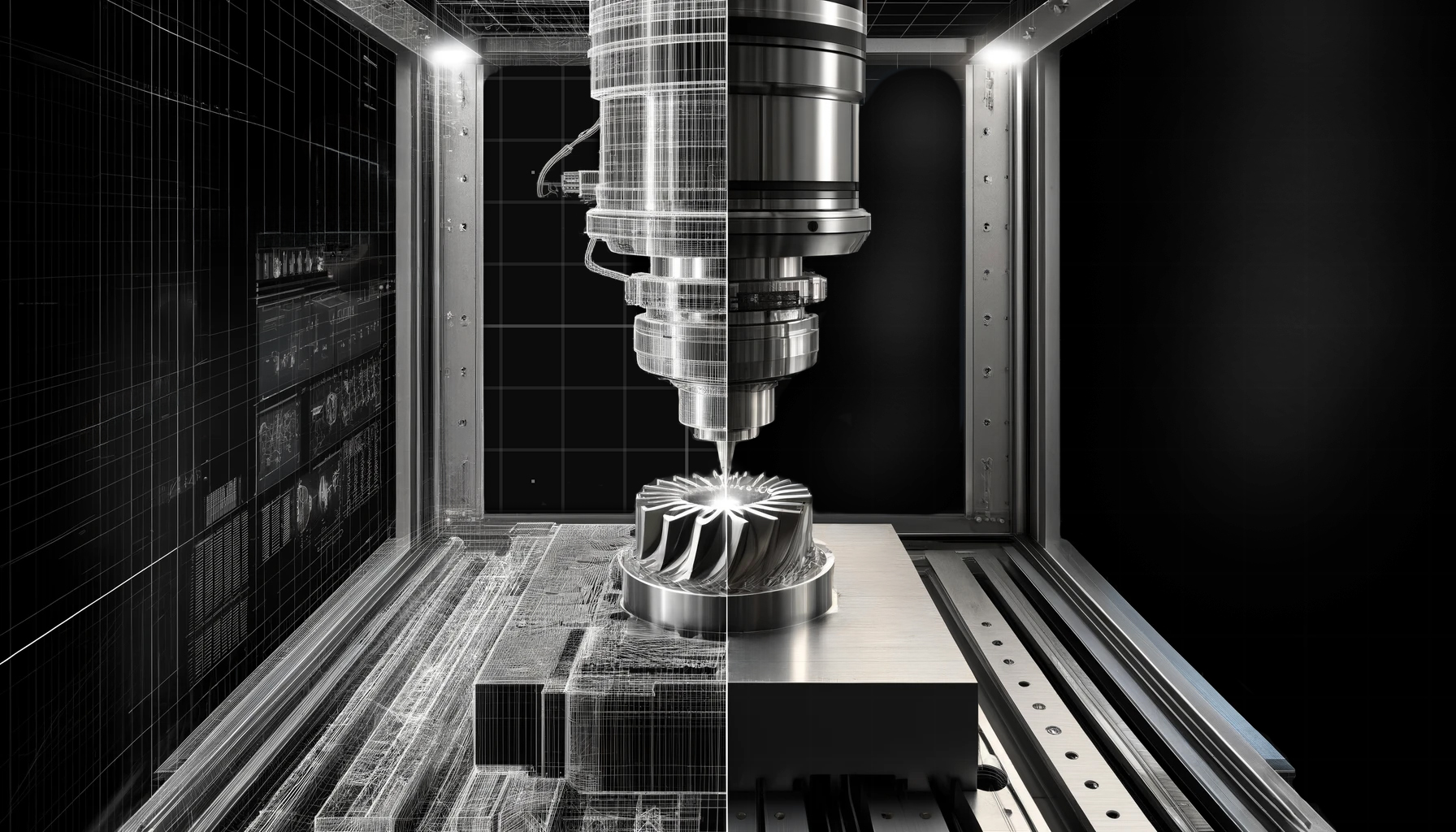

Mastering CNC Machining: The Power of Fixtures

They serve as the backbone for holding workpieces securely and consistently in position during machining operations. You see, without fixtures, your parts would be all over the place, ruining your chances of achieving precision and repeatability.

Not only do fixtures make sure that each part meets exacting specifications, they also minimize errors and maximize efficiency. They reduce setup times and allow for uninterrupted, automated production. And ultimately, they save you costs and improve product quality. Who knew these little tools could have such a big impact? Now that you know the significance of fixtures in CNC machining, let’s dive deeper into the different types of fixtures and their applications.

The Significance of Fixtures in CNC Machining

Types of Fixtures and Their Applications

We have dedicated fixtures. These custom-designed fixtures are tailored for a particular part or component, ensuring optimal accuracy and repeatability. They’re perfect for high-volume production where consistency is key. Then we have general fixtures, that can accommodate a range of workpieces. They’re ideal for small to medium-sized batches or when part variety is essential.

Now that you know the different types of fixtures, it’s time to consider something equally important: toolpath optimization. Prudent planning of toolpaths and fixture design is essential to avoid collisions between the cutting tool and fixture components.

But what about maintenance and troubleshooting? Regular cleaning and lubrication keep them in tip-top shape. Periodic inspections help identify and rectify any signs of wear, damage, or misalignment. And when issues like slippage or misalignment arise, prompt troubleshooting minimizes downtime and keeps production efficiency soaring.

Innovations are always on the horizon, and CNC machining fixtures are no exception. Fancy some 3D printing of fixtures? Additive manufacturing techniques allow for rapid prototyping and custom fixture creation, reducing lead times. And how about smart fixtures? By integrating sensors and monitoring systems, they provide real-time feedback, improving process control and efficiency.

So what does the future hold for CNC machining fixtures? Brace yourself for the integration of artificial intelligence (AI), which will optimize fixture designs and toolpaths for increased efficiency and reduced material waste. And let’s not forget about sustainability. As environmental concerns grow, there will be a focus on eco-friendly materials and processes to minimize the fixture production’s environmental impact.

With these fixtures by your side, you’ll be well on your way to mastering CNC machining.

Toolpath Optimization and Fixture Considerations

When it comes to achieving top-notch results in CNC machining, toolpath optimization is key. We don’t want any collisions between the cutting tool and the fixture components – that would be a disaster! So, careful planning of the toolpath and well-designed fixtures go hand in hand to ensure a smooth operation. Fixture integration into the CAM software comes into play here, streamlining the entire machining process.

But wait, there’s more! Fixture maintenance and troubleshooting are crucial too. We can’t just neglect our fixtures and expect them to perform flawlessly forever. Regular cleaning and lubrication are necessary to prevent wear and tear. And let’s not forget about inspections – periodic check-ups to identify any signs of wear, damage, or misalignment are essential. Addressing issues such as slippage or misalignment promptly is vital to minimize downtime and maintain production efficiency.

So, the next time you’re delving into CNC machining, remember the importance of collision avoidance and fixture integration. Keep those fixtures well-maintained and troubleshoot issues as soon as they arise.

Fixture Maintenance and Troubleshooting

Fixtures play a vital role in CNC machining, keeping workpieces securely in place during machining operations. They are the unsung heroes behind the precision and repeatability associated with CNC machining. Fixtures require proper maintenance and troubleshooting to ensure consistent performance and longevity.

One of the essential tasks in fixture maintenance is cleaning and lubrication. Regularly cleaning and lubricating fixture components is crucial to prevent wear and maintain clamping effectiveness. You wouldn’t want your fixtures to lose their grip and start slipping during machining, would you? That would be disastrous! So, make sure to give them a bit of TLC.

Another important aspect of fixture maintenance is inspection. Periodic inspections allow you to identify and rectify any signs of wear, damage, or misalignment. Imagine if you didn’t catch that misalignment on time. It could lead to costly errors and delays in production. So, keep a close eye on your fixtures and fix any issues before they escalate.

And of course, when it comes to troubleshooting, prompt action is key. If you notice slippage, misalignment, or deformation, address these issues immediately. Ignoring them will only lead to more downtime and decreased production efficiency. So, be proactive and tackle those problems head-on!

Maintaining and troubleshooting fixtures may not be the most glamorous part of CNC machining, but it is absolutely necessary. By taking care of your fixtures, you ensure that they continue to do their job effectively, allowing you to produce high-quality parts and save time and money.

To summarize, fixture maintenance involves regular cleaning and lubrication, periodic inspections, and prompt troubleshooting. So, don’t neglect your fixtures! Give them the attention they deserve, and they will reward you with precise and efficient machining.

Innovations in CNC Machining Fixtures

3D Printing of Fixtures: Say goodbye to the traditional manufacturing methods, because 3D printing has entered the world of CNC machining fixtures with a bang! This innovative technique allows for rapid prototyping and custom fixture creation, reducing lead times and increasing design flexibility. Need a fixture with complex geometries or intricate designs? No problem! Just press a few buttons, and voila! Your fixture is ready to take on any machining challenge.

Smart Fixtures: As if fixtures weren’t already smart enough, now we have “smart fixtures” adding a whole new level of intelligence to the CNC machining game. These fixtures are equipped with sensors and monitoring systems that enable real-time feedback and process control. They can detect any deviations in the machining process and make adjustments on the fly. It’s like having a fixture that can think for itself! Smart fixtures improve efficiency, reduce errors, and ensure consistent quality.

In conclusion, the world of CNC machining fixtures is undergoing a revolution. With 3D printing and smart fixtures paving the way, the possibilities are endless. So, hop on the innovation train and embrace these cutting-edge technologies to unlock the true power of fixtures in CNC machining.

Future Trends in Fixture Technology

The evolution of fixture technology is a focal point driving efficiency and precision. This exploration into “Future Trends in Fixture Technology” aims to dissect transformative shifts that will redefine workholding solutions. From enhanced automation to adaptive technologies, this discussion navigates the path towards a future where fixture technology plays a pivotal role in optimizing manufacturing processes.

Artificial Intelligence (AI) Integration:

Sustainable Materials:

With the growing need for environmentally friendly practices, sustainability in CNC machining fixtures is gaining importance. Manufacturers are now looking for materials that can be easily recycled or reused at the end of their lifecycle. Sustainable fixture designs take into account the entire life cycle of the fixture, from production to disposal. Utilizing eco-friendly materials not only reduces the environmental impact but also showcases a company’s commitment to sustainability. So, imagine a world where fixtures are not only efficient and precise but also eco-friendly. By embracing sustainable materials, CNC machining can become a greener and more responsible industry.

The future of fixture technology in CNC machining is bright and promising, with AI integration and sustainable materials leading the way. These advancements will not only revolutionize the way we approach CNC machining but also contribute to a more efficient, cost-effective, and sustainable manufacturing industry. So, buckle up and get ready for a future where fixtures are smarter, greener, and more efficient than ever before.

Workholding Techniques for CNC Machines

When it comes to CNC machining, workholding techniques are an essential aspect that ensures the workpiece stays firmly in place during machining. Let’s dive into the key techniques:

Jigs and Fixtures: These custom-designed tools are like the superheroes of work holding. They come to the rescue when you have complex workpieces that need precision machining. Jigs and fixtures provide a secure grip on the workpiece, allowing the CNC machine to work its magic with utmost accuracy.

Vacuum Chucks: Picture this – delicate and thin materials flying all over the place during machining. Sounds like a nightmare, right? Well, not if you have vacuum chucks. These ingenious devices use the power of suction to hold those delicate materials in place.

Magnetic Workholding: Ever wondered how you can securely hold ferrous workpieces? Enter magnetic workholding. These magnetic marvels use the power of magnets to grip and hold ferrous materials during machining. With magnetic workholding, you can say goodbye to time-consuming setup and hello to increased efficiency.

So, whether your workpiece is complex and needs a custom solution or delicate and requires a gentle touch, CNC machining has the right workholding technique for the job. From jigs and fixtures to vacuum chucks and magnetic workholding, these techniques ensure that your parts stay put during the machining process.

With these techniques in your arsenal, you’ll have the power to conquer any CNC machining challenge that comes your way. So, tighten those screws, fire up the machines, and let the workholding techniques do their magic.

Conclusion

In conclusion, ensuring precision and repeatability in operations. Dedicated fixtures excel in high-volume production, while general fixtures offer versatility for smaller batches. Modular fixtures provide adaptability to various workpiece shapes. Explore more blogs by Ethereal Machines to master CNC machining techniques.

Optimizing toolpaths and integrating fixture design is vital for top-notch results. Regular fixture maintenance ensures consistent performance. Exciting advances include 3D printing for rapid prototyping, sensors for real-time feedback, and AI-driven designs. The future promises AI-optimized fixtures and eco-friendly materials.

To delve deeper into CNC machining’s intricacies, read Ethereal Machines’ blogs. Unlock the potential of fixtures for precision and efficiency.

On-demand CNC Machining Services by Ethereal Machines offers the perfect solution for your CNC machining needs. With secure and confidential processes, you can get an instant quote and access expert advice from their technical team. Whether you need custom CNC machined parts or have a specific project in mind, Ethereal Machines is committed to helping you every step of the way. Try MAAS now and achieve your goals with ease.

Views: 194