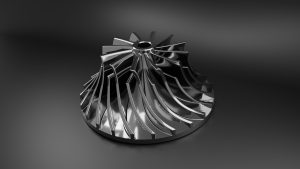

CERTIFIED FOR EXCELLENCE

Leaders in CNC Component Manufacturing.

Please fill out the form below andwe will get back to you pronto!

Please fill out the form below andwe will get back to you pronto!

Views: 41

Please fill out the form below andwe will get back to you pronto!

Please fill out the form below andwe will get back to you pronto!

Please fill out the form below andwe will get back to you pronto!

Please fill out the form below andwe will get back to you pronto!

Join our Mailing List

Stay updated with all things Ethereal!