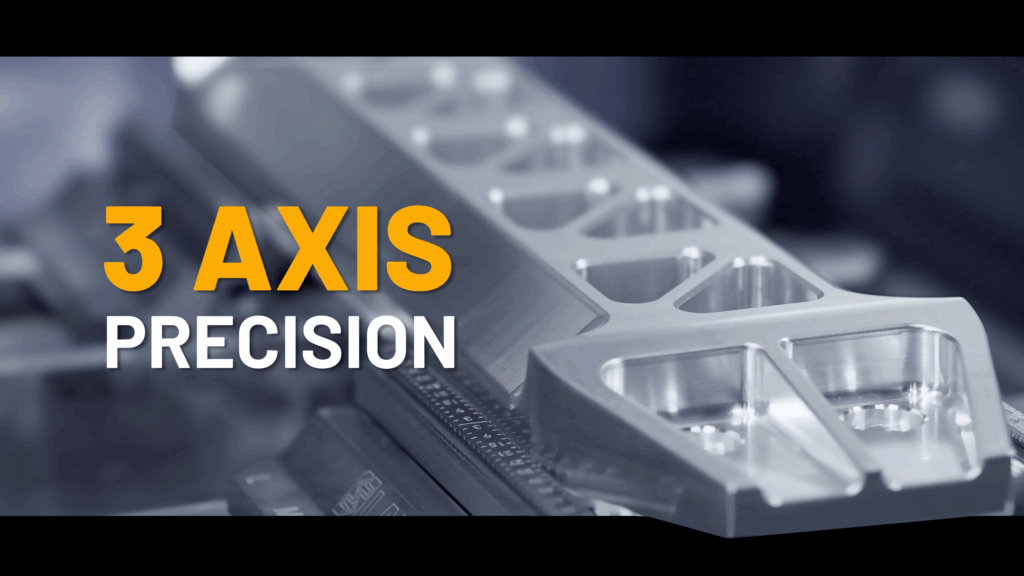

Aura: Ethereal’s 3-Axis CNC Engineered for Production

A Commitment Beyond the Shop Floor

Launching Aura on the eve of India’s Independence Day is our way of marking what self-reliance means in manufacturing. Every part of Aura—its design, build, and validation—was done under one roof here in India. For us, engineering capability at home is as much a contribution to the nation’s future as it is to our customers’ success.

Precision Built In. At Scale.

Aura is Ethereal’s in-house 3-axis CNC system, engineered to keep design intent intact at production pace: ±4 µm positional accuracy (about one-twentieth of a human hair) while moving at 48 m/min. Aura is the standard that partners and future teammates rely on when they work with Ethereal.

Why Aura Exists

Production quality isn’t only about how precise you can be once. It’s about how accurate you remain hour after hour, shift after shift, component after component. Aura was developed to make that consistency the default—by aligning machine structure, motion control, fixturing, tooling, and data into one disciplined system. When standards rise, they should rise for every component, not just the first few.

Key Specs → Real-World Consequences

Specifications matter when they hold up in production. Here’s how Aura’s numbers translate into repeatable outcomes on our floor.

* Accuracy note: Performance depends on material, geometry, tooling, and temperature. We validate per part family under production conditions.

For the multi-axis perspective, see how our five-axis sibling Nimbus applies the same discipline to more complex geometries.

If You Source Precision Parts

The outcome we aim for is simple: predictable geometry and predictable time. Share your drawing and constraints; we’ll show how our process behaves on your part before you commit

If You Want Harder Problems

If your idea of progress is improving motion, control, and inspection, join us to build what comes after Aura.

Views: 2573